Preparation method of anti-falling lithium ion battery

A lithium-ion battery, anti-drop technology, applied in the direction of electrode manufacturing, secondary batteries, circuits, etc., can solve the problems of increasing scrap cost, difficulty in meeting requirements, and low coating efficiency, so as to reduce scrap cost and realize large-area coating effect of coating and improving coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the specific embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

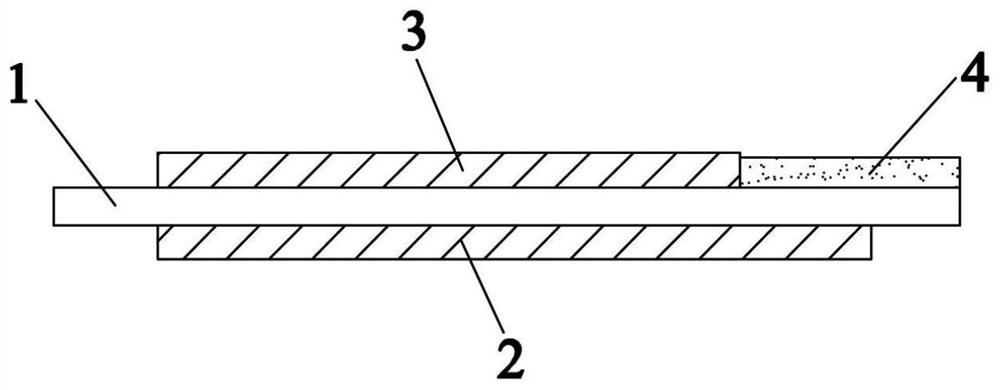

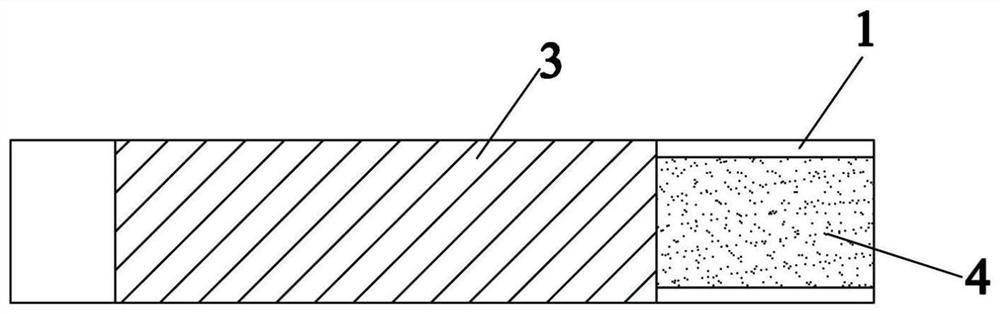

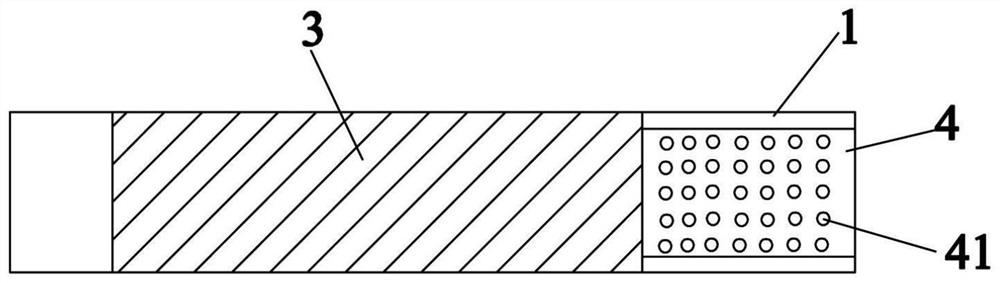

[0031] refer to Figure 1~5 , in one embodiment of the preparation method of the anti-drop lithium-ion battery of the present invention, it comprises the following steps:

[0032] 1) Prepare the anode slurry, apply it on the anode current collector, cold press and slitting to form the anode pole piece;

[0033] 2) Prepare the cathode slurry, apply it on the cathode current collector 1, and reserve an empty foil area at the tail of the cathode current collector 1 in the winding direction, set an adhesive layer 4 in the empty foil area, cold press, Forming cathode pole pieces by strips; wherein, the order of the two steps of setting and cold pressing of the adhesive layer 4 can be exchanged;

[0034] 3) The anode pole piece, the diaphragm and the cathode pole pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com