Plastic package residual glue removing device suitable for frame type semiconductor

A technology for removing glue residue and semiconductor, applied in the field of plastic packaging of semiconductor products, which can solve the problems of affecting tool life, electrical risk, tool damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the present invention will be specifically introduced with reference to the drawings and specific embodiments.

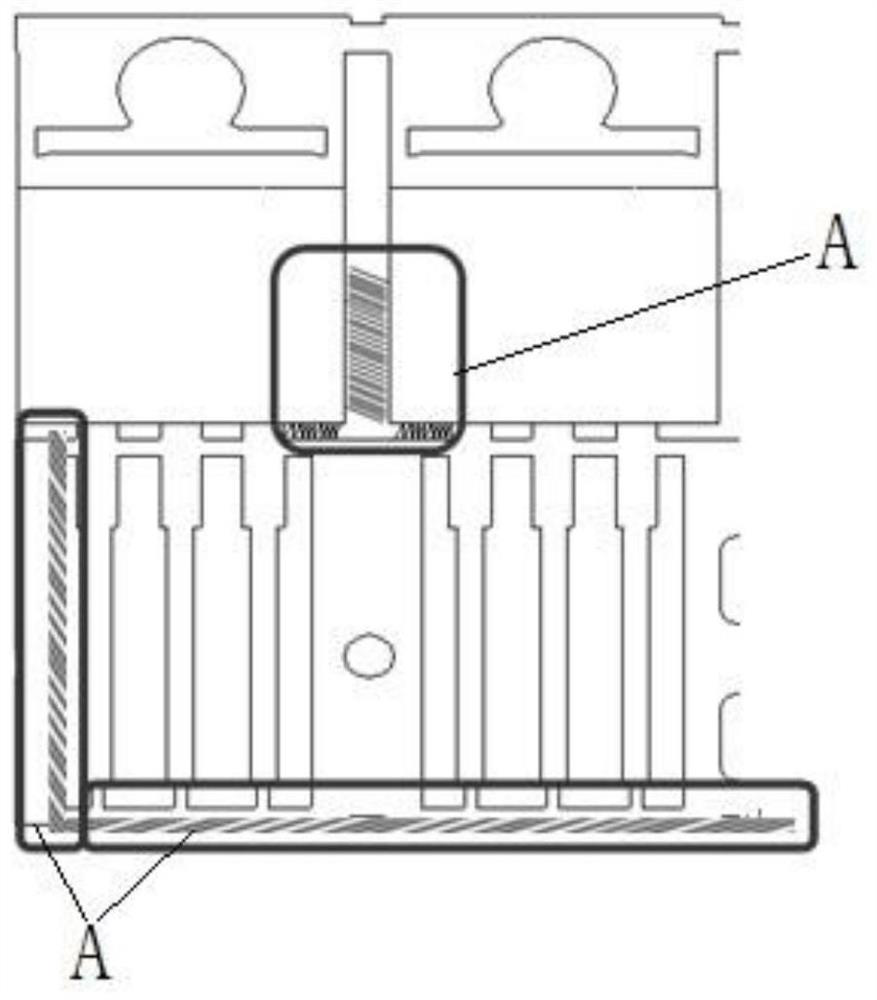

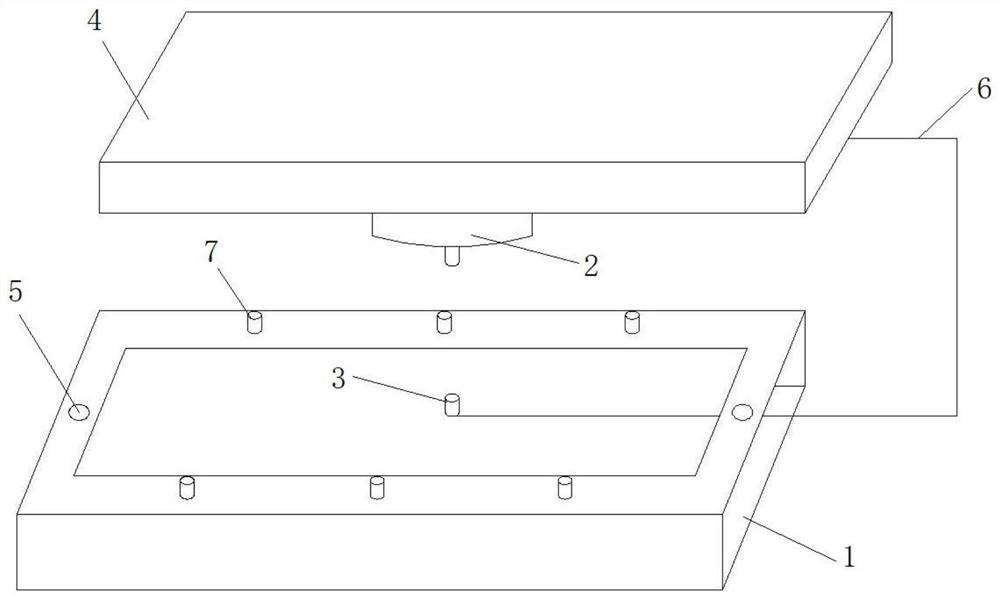

[0035] A plastic encapsulation residue removal device suitable for frame type semiconductors is composed of a control device, a frame, a laser generator, a laser receiver, a residue detection device and a plane positioning device.

[0036] Several limit blocks for fixing semiconductors and infrared sensors for sensing semiconductors are arranged on the frame. The laser generator is suspended on the top of the frame through a plane positioning device, and the plane positioning device includes a horizontal X axis and a longitudinal Y axis respectively driven by a control device through a motor.

[0037] The laser receiver is arranged at the bottom of the frame corresponding to the laser generator, and the laser receiver and the laser generator are fixed by a connecting rod, and the plane displacement can be synchronized to ensure emission and reception.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com