Three-point positioning type combined circular cutter seat of gull-wing ejector block structure

A three-point positioning, circular blade technology, applied in the direction of cutting tools, shearing equipment, shearing devices, etc. for shearing machines, can solve the problems of unsupported longitudinal shearing tools and damage to longitudinal shearing tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

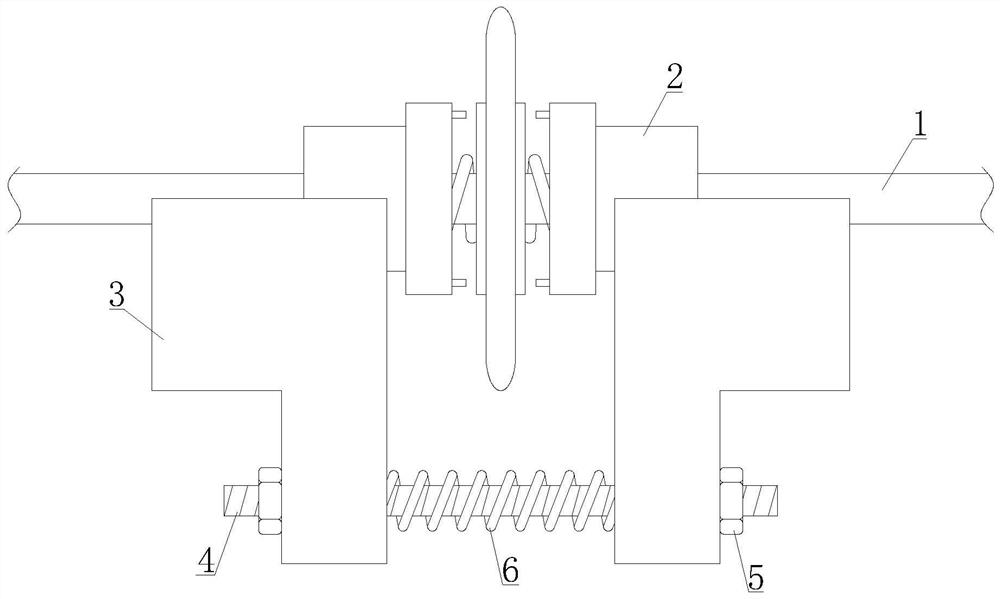

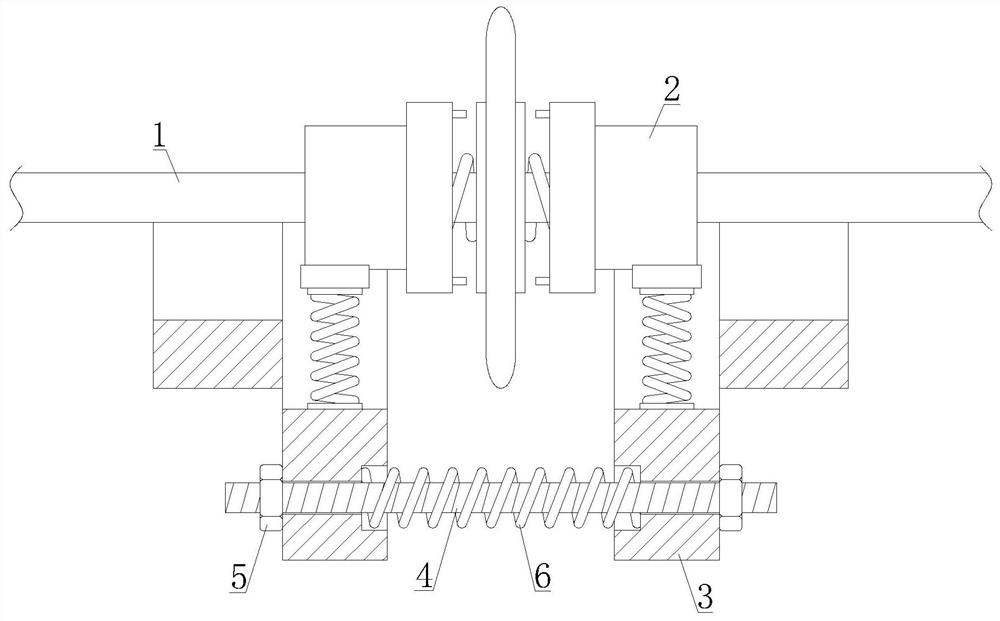

[0026] see Figure 1-Figure 2 , a three-point positioning combined circular blade tool seat of a gull-wing top block structure, including a slitting main shaft 1, a three-point slitting tool 2, a gull-wing support unit 3, an adjusting screw 4, an adjusting nut 5 and an adjusting Spring 6, a three-point slitting tool 2 is installed on the slitting main shaft 1, the left and right ends of the lower side of the three-point slitting tool 2 are respectively provided with a gull-wing support unit 3, and an adjusting screw is installed between the lower sides of the gull-wing support unit 3 4. Adjusting nuts 5 are respectively installed at both ends of the adjusting screw 4, and an adjusting spring 6 is provided on the outside of the adjusting screw 4 between the gull-wing support units 3. The adjustment spring 6 is assembled to form a gull-wing type support top block.

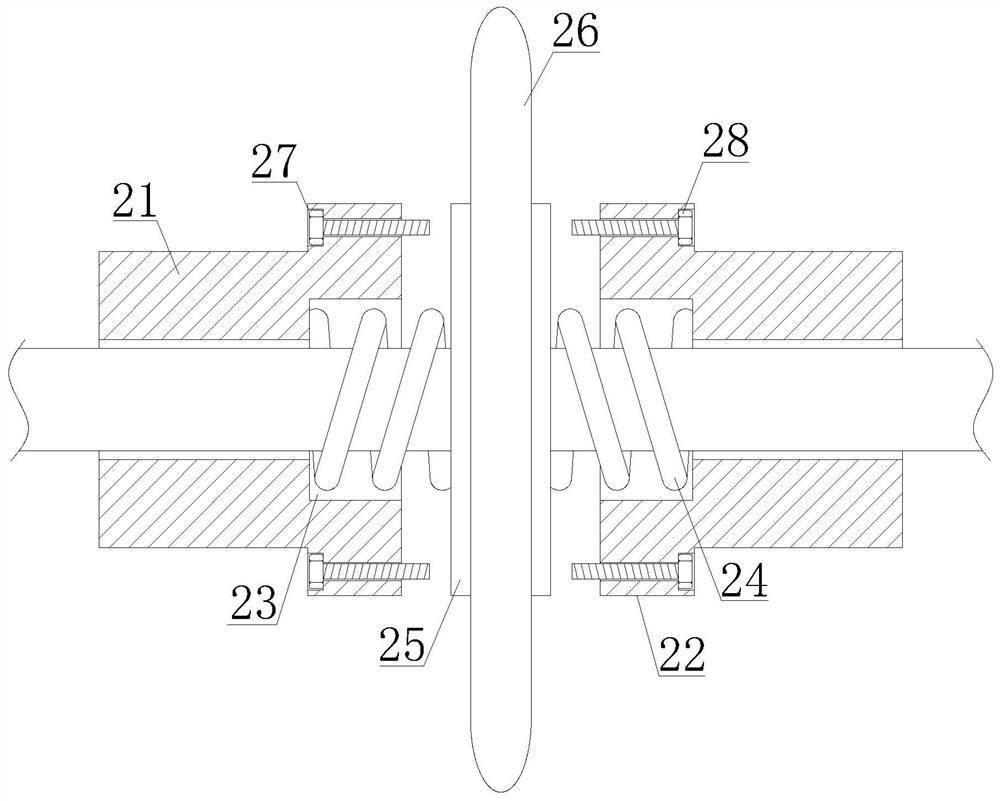

[0027] see image 3 , the three-point slitting tool 2 includes an outer clamping sleeve 21, an inner clamping sl...

Embodiment 2

[0032] see Figure 1-Figure 2 , a three-point positioning combined circular blade tool seat of a gull-wing top block structure, including a slitting main shaft 1, a three-point slitting tool 2, a gull-wing support unit 3, an adjusting screw 4, an adjusting nut 5 and an adjusting Spring 6, a three-point slitting tool 2 is installed on the slitting main shaft 1, the left and right ends of the lower side of the three-point slitting tool 2 are respectively provided with a gull-wing support unit 3, and an adjusting screw is installed between the lower sides of the gull-wing support unit 3 4. Adjusting nuts 5 are respectively installed at both ends of the adjusting screw 4, and an adjusting spring 6 is provided on the outside of the adjusting screw 4 between the gull-wing support units 3. The adjustment spring 6 is assembled to form a gull-wing type support top block.

[0033] see image 3 , the three-point slitting tool 2 includes an outer clamping sleeve 21, an inner clamping sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com