Rapid emptying ballast tank

A technology of ballast tanks and ballast water tanks, which is applied to some cabins in the hull, ships, hulls, etc., and can solve problems such as large spacing, reduced drainage efficiency, and easy blockage of water holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

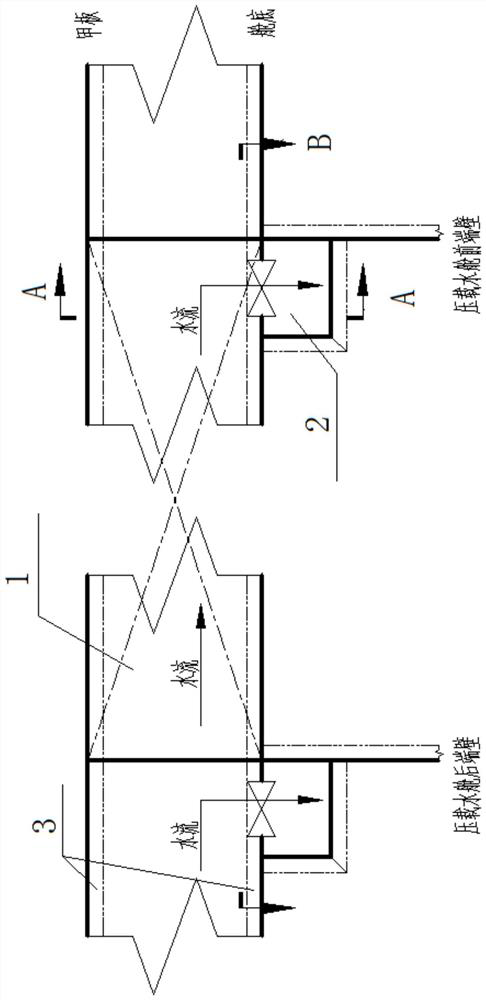

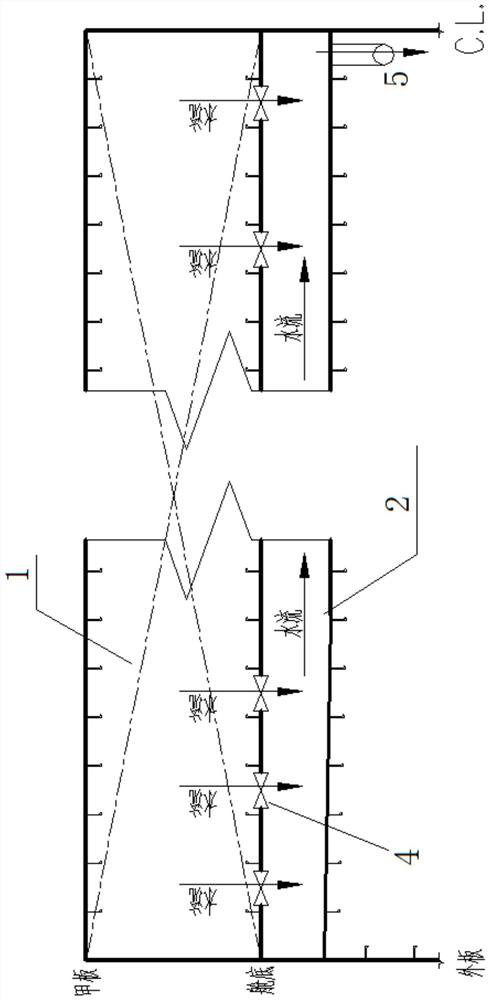

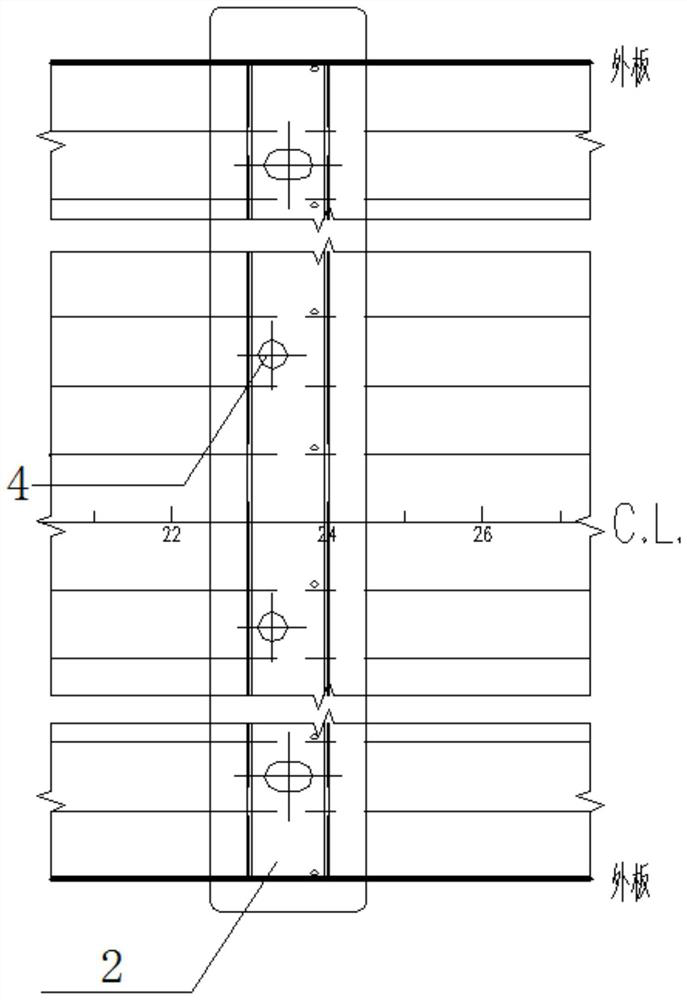

[0028] see Figure 1-Figure 3 , a fast emptying ballast tank, comprising a ballast water tank 1, at the bottom of the ballast water tank 1, a diversion groove 2 is arranged outside the ballast water tank 1, and the direction of the diversion groove 2 is perpendicular to The direction of the upwardly protruding aggregate 4 at the bottom of the ballast water tank; select the positions between several adjacent aggregates 4 to set diversion holes 4, so that the ballast water tank 1 and the diversion groove 2 are kept in communication; At least one ballast tank water outlet 5 is provided at the bottom of the diversion tank 2 .

[0029] In this example, see Figure 1-3 , the transverse section and longitudinal section of the ballast water tank 1 are both rectangular, the aggregates 4 are arranged along the axial direction of the hull, the diversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com