Barreled solidified grease discharging device

A technology of unloading device and grease, applied in the directions of loading/unloading, packaging, transportation and packaging, which can solve the problems of adhesion, low unloading efficiency and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

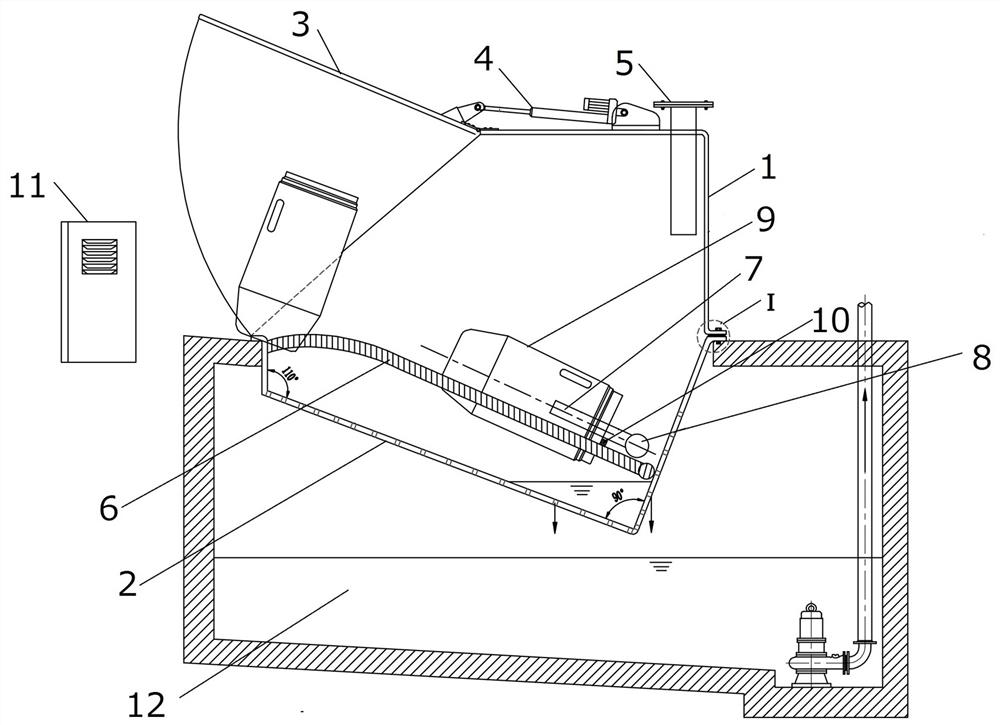

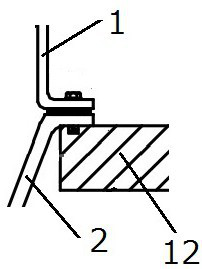

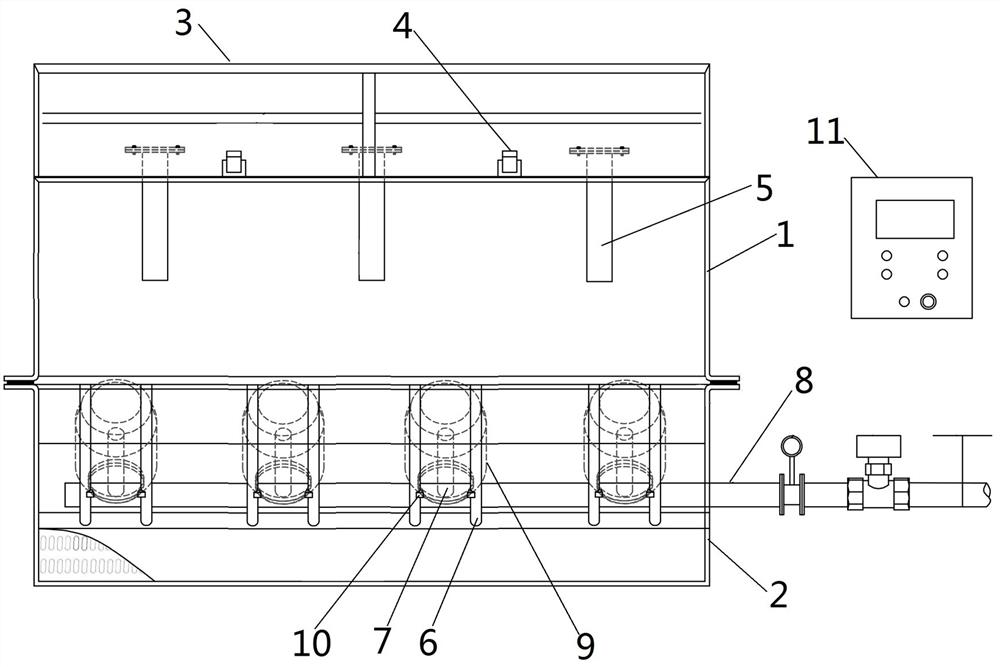

[0022] Such as Figure 1~3 As shown, a barreled solidified grease unloading device includes a trapezoidal hopper cover 1 and a hopper 2 . All parts of the unloading device may be in contact with the material. In order to ensure that they are not corroded, all parts are made of 304 stainless steel.

[0023] The bottom of the hopper cover 1 is fully open, and one side of the hopper cover 1 is provided with a discharge port, and the discharge port is provided with a cover plate 3, and all the other sides are sealed. The cover plate 3 is connected with the hopper cover 1 through hinges or hinges. An electric push rod 4 is fixed on the top of the hopper cover 1 , and the telescopic end of the electric push rod 4 is connected with the cover plate 3 . The opening and closing of the cover plate 3 is controlled by the electric push rod 4, and the electric push rod 4 retracts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com