Vacuum heat insulation glass

A vacuum heat insulation and glass technology, applied in the field of glass, can solve the problems of being unable to resist the spread of fire and poor fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

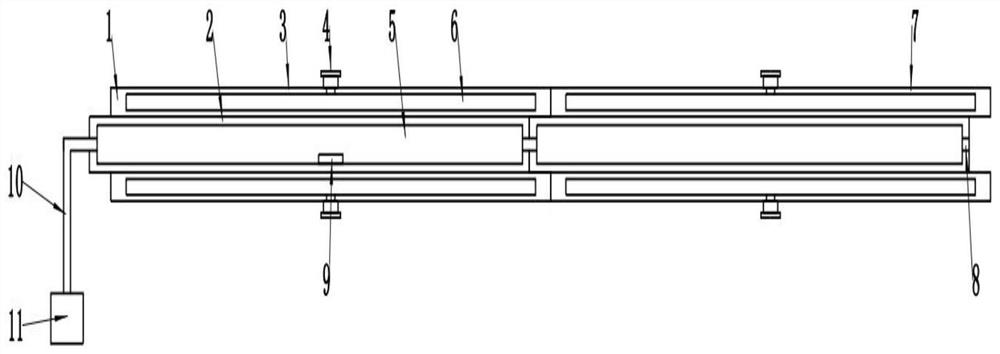

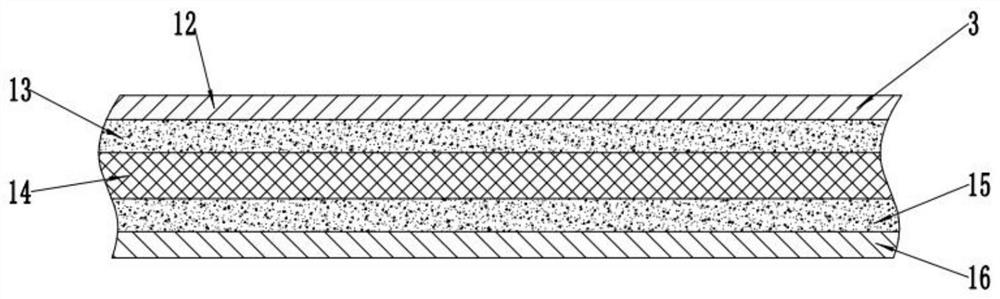

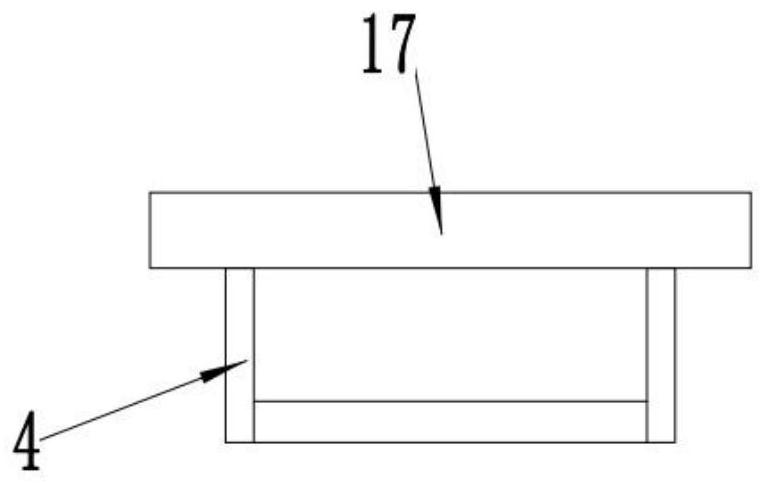

[0034] see figure 1 and 3 , in an embodiment of the present invention, a vacuum heat insulating glass includes a base glass 1 and at least one piece of connecting glass 7; 2 and two glass substrates 3 symmetrically arranged on the front and rear sides of the base glass 1. The laminated glass 2 and the two glass substrates 3 form a convex structure on the left and a concave structure on the right, so that the base glass 1 and the connecting glass 7 can be installed together. ;

[0035] There is a first cavity 5 inside the laminated glass 2, and two through holes 8 are symmetrically opened on the left and right sides of the laminated glass 2. When the base glass 1 and the connecting glass 7 are connected and installed, the first cavity 5 inside the base glass 1 A cavity 5 communicates with the first cavity 5 inside the connecting glass 7 through a through hole 8, so that the first cavity 5 inside the base glass 1 and the first cavity 5 inside the connecting glass 7 form an int...

Embodiment 2

[0038] see figure 1 and 3 -4. In the embodiment of the present invention, a vacuum insulation glass includes a base glass 1 and at least one connecting glass 7; the base glass 1 and the connecting glass 7 have the same structure, and the base glass 1 and the connecting glass 7 are made of one piece The laminated glass 2 is composed of two glass substrates 3 symmetrically arranged on the front and rear sides of the base glass 1. The laminated glass 2 and the two glass substrates 3 form a convex structure on the left and a concave structure on the right, so that the base glass 1 and the connecting glass 7 Cooperate with installation;

[0039]There is a first cavity 5 inside the laminated glass 2, and two through holes 8 are symmetrically opened on the left and right sides of the laminated glass 2. When the base glass 1 and the connecting glass 7 are connected and installed, the first cavity 5 inside the base glass 1 A cavity 5 communicates with the first cavity 5 inside the co...

Embodiment 3

[0043] see Figure 1-3 , in an embodiment of the present invention, a vacuum heat insulating glass includes a base glass 1 and at least one piece of connecting glass 7; 2 and two glass substrates 3 symmetrically arranged on the front and rear sides of the base glass 1. The laminated glass 2 and the two glass substrates 3 form a convex structure on the left and a concave structure on the right, so that the base glass 1 and the connecting glass 7 can be installed together. ;

[0044] There is a first cavity 5 inside the laminated glass 2, and two through holes 8 are symmetrically opened on the left and right sides of the laminated glass 2. When the base glass 1 and the connecting glass 7 are connected and installed, the first cavity 5 inside the base glass 1 A cavity 5 communicates with the first cavity 5 inside the connecting glass 7 through a through hole 8, so that the first cavity 5 inside the base glass 1 and the first cavity 5 inside the connecting glass 7 form an integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com