Gypsum slurry as well as preparation method and application thereof

A technology of gypsum slurry and gypsum, which is applied in the field of gypsum slurry and its preparation, and can solve the problems of prolonging the drying time of paper-faced gypsum boards, setting time of gypsum boards, and high water consumption for mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0033] Sulfonic acid group modified polycarboxylate water reducer, refer to "Synthesis and performance research of sulfonic acid group modified polycarboxylate water reducer" (Gao Yujun et al., "Chemical Research and Application", Volume 29, Issue 4 , April 2017, DOI: 10.3969 / j.issn.1004-1656.2017.04.011). The specific preparation method is: APEG-700 modified with sulfonic acid group is used as the optimal comonomer, and in the copolymerization system n(TPEG):n(APEGS):n(AA):n(MA):n(EVAc) The ratio is 1.0:0.25:3.0:2.0:1.0, the synthesized sulfonic acid group modified polycarboxylate water reducer.

Embodiment 1

[0035] (1) Mix the modified starch, the sulfonic acid-modified polycarboxylate water reducer obtained in Preparation Example 1, sodium lauryl sulfate, sodium sulfate and water to obtain solution I;

[0036] (2) Mix desulfurized gypsum that has been dried at 80° C. for 1 hour and cooled to room temperature with solution I to obtain gypsum slurry.

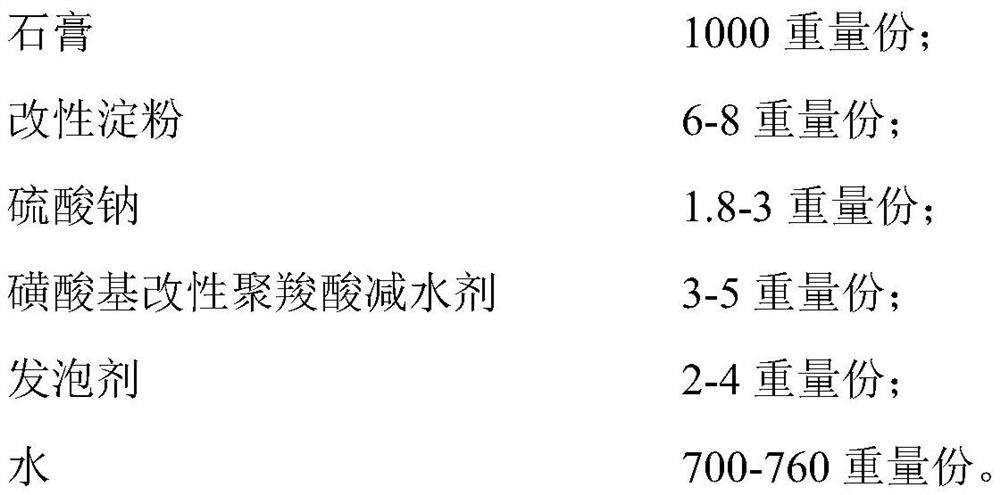

[0037] Wherein, the consumption of each substance is:

[0038]

[0039]

Embodiment 2

[0041] (1) Mix the modified starch, the sulfonic acid-modified polycarboxylate water reducer obtained in Preparation Example 1, sodium lauryl sulfate, sodium sulfate and water to obtain solution I;

[0042] (2) Mix desulfurized gypsum that has been dried at 80° C. for 1 hour and cooled to room temperature with solution I to obtain gypsum slurry.

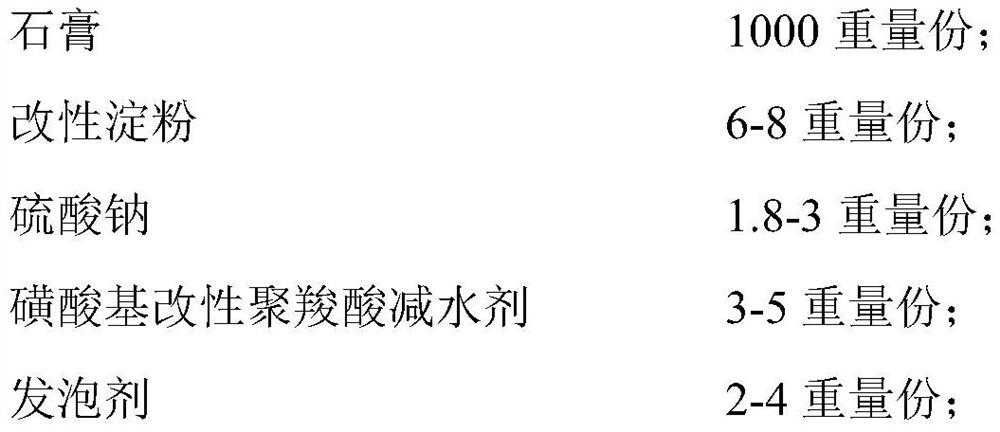

[0043] Wherein, the consumption of each substance is:

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com