Sleeve type underwater pile-sinking positioning frame device with auxiliary pile and construction method

A technology of auxiliary pile and positioning frame, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of self-heavy, poor leveling system stability and high construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

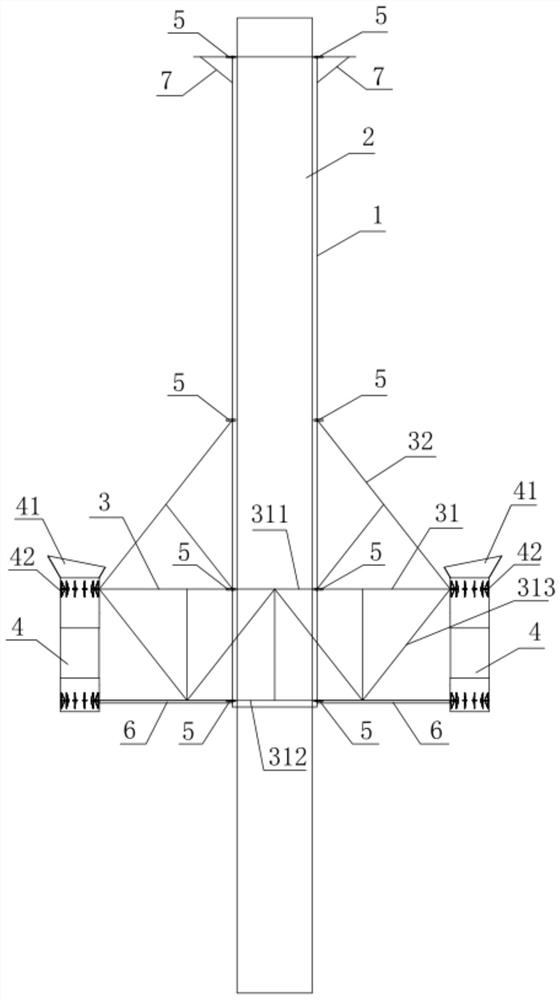

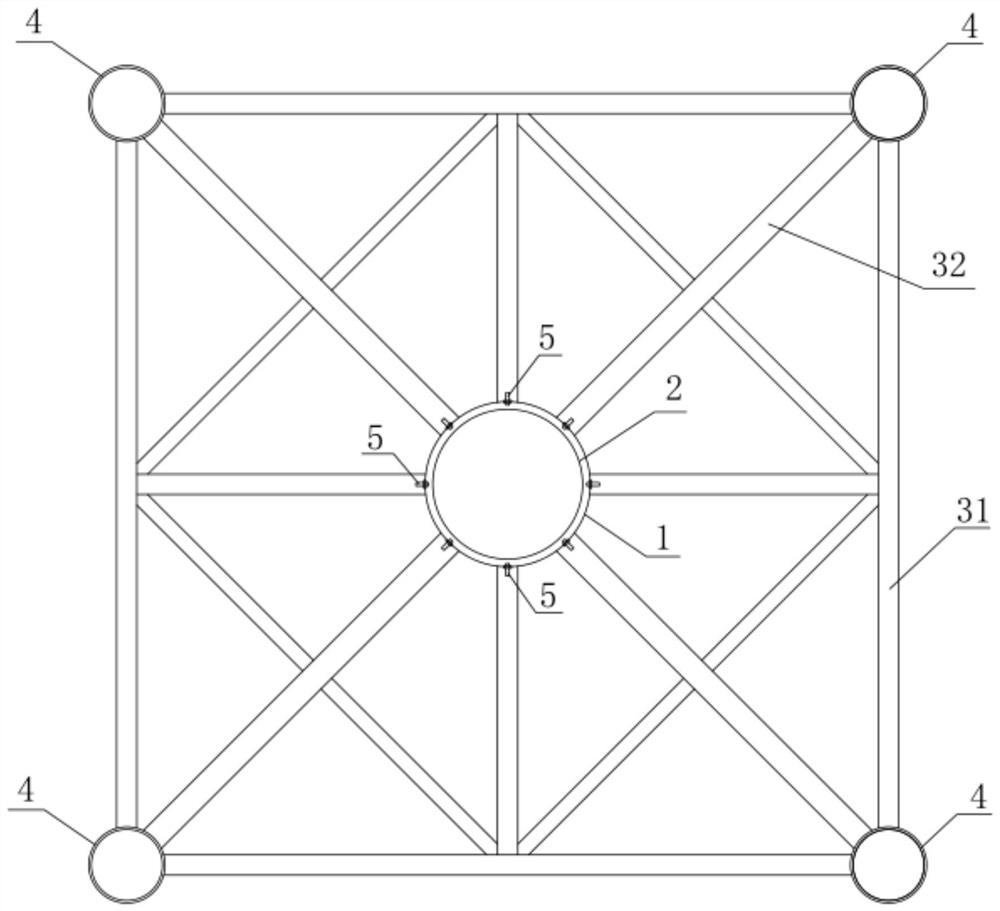

[0043] Such as figure 1 and figure 2 Shown is a sleeve-type underwater pile positioning frame device with auxiliary piles, including an intermediate casing 1, a positioning frame 3, an engineering pile casing 4 and a leveling device. Wherein, the intermediate casing 1 is an upright hollow cylindrical structure, which is used for socketing with the auxiliary pile 2 . The positioning frame 3 is square and is welded on the outer periphery of the bottom end of the intermediate casing 1 , and the center of gravity of the positioning frame 3 is located on the axis of the intermediate casing 1 . There are four engineering pile sleeves 4 and they are located on the four corners of the positioning frame 3 respectively. The geometric centers of the four engineering pile sleeves 4 are located on the axis of the middle sleeve 1; Inserted cylindrical space. There are four sets of leveling devices arranged axially along the intermediate casing 1, and each set of leveling devices include...

Embodiment 2

[0051] The embodiment of the present invention also provides a construction method of a sleeve-type underwater pile-sinking positioning frame device with auxiliary piles, which is used to drive the above-mentioned sleeve-type underwater pile-sinking positioning frame device with auxiliary piles into the bottom of the water, Specifically include the following steps:

[0052] Step S10, auxiliary pile sinking operation: using a vibratory hammer to drive the auxiliary pile at a predetermined position on the bottom of the water, and using the vibratory hammer to adjust the verticality of the auxiliary pile during the piling process;

[0053] Step S20, inserting the pile sinking positioning frame: inserting the pile sinking positioning frame into the auxiliary pile from the middle sleeve, so that the pile sinking positioning frame enters the bottom of the water along the guide of the auxiliary pile, and makes the anti-sinking position at the bottom of the pile sinking positioning fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com