Railway slope prefabricated and assembled post-poured framework slope protection structure and construction method thereof

A prefabricated assembly and slope technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of multiple prefabricated block types and complex block shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

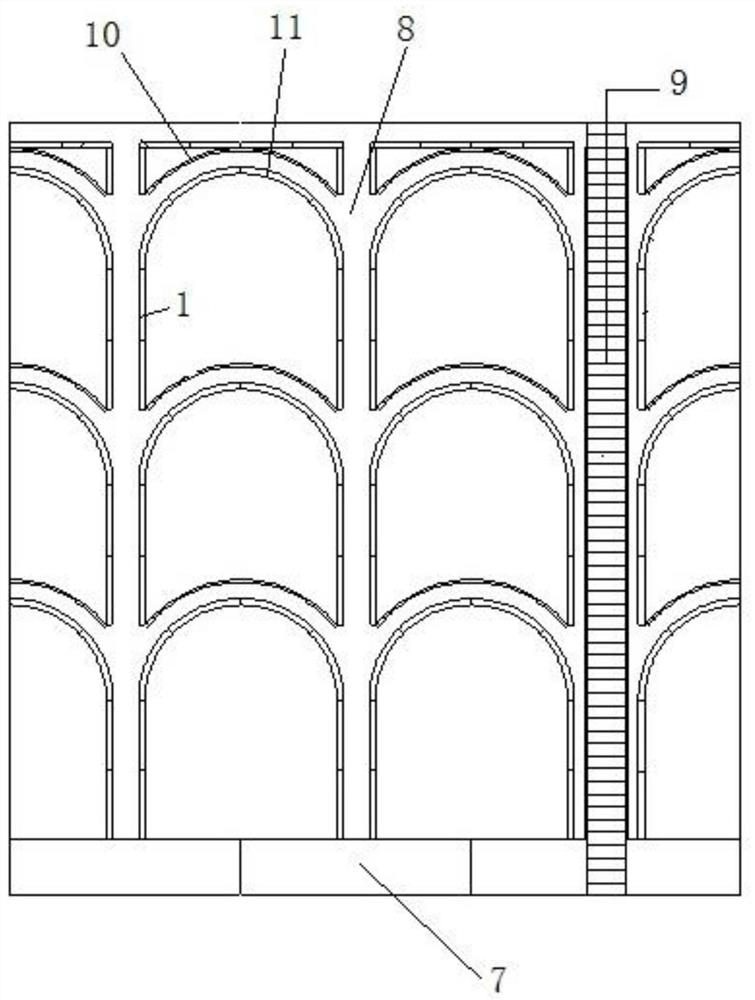

[0050] Such as figure 1 As shown, a kind of railway slope prefabricated and assembled post-casting skeleton slope protection structure of the present invention includes: multiple slope protection units, inspection ladder steps 9, concrete foot protection 7 and post-cast concrete core column 8, and multiple slope protection units repeat The combined form extends longitudinally and vertically on the railway slope (wherein, the longitudinal direction refers to the length direction of the slope, and the vertical direction refers to the height direction of the slope);

[0051] Each slope protection unit is composed of a main frame and a supporting frame, which are used to limit the pouring range of the post-cast concrete core column 8 on the slope. The main frame is composed of a plurality of side prefabricated panels 1 and a plurality of top prefabricated panels 11 Assembled, a plurality of said side prefabricated panels 1 are assembled into the side main frame on both sides of th...

Embodiment 2

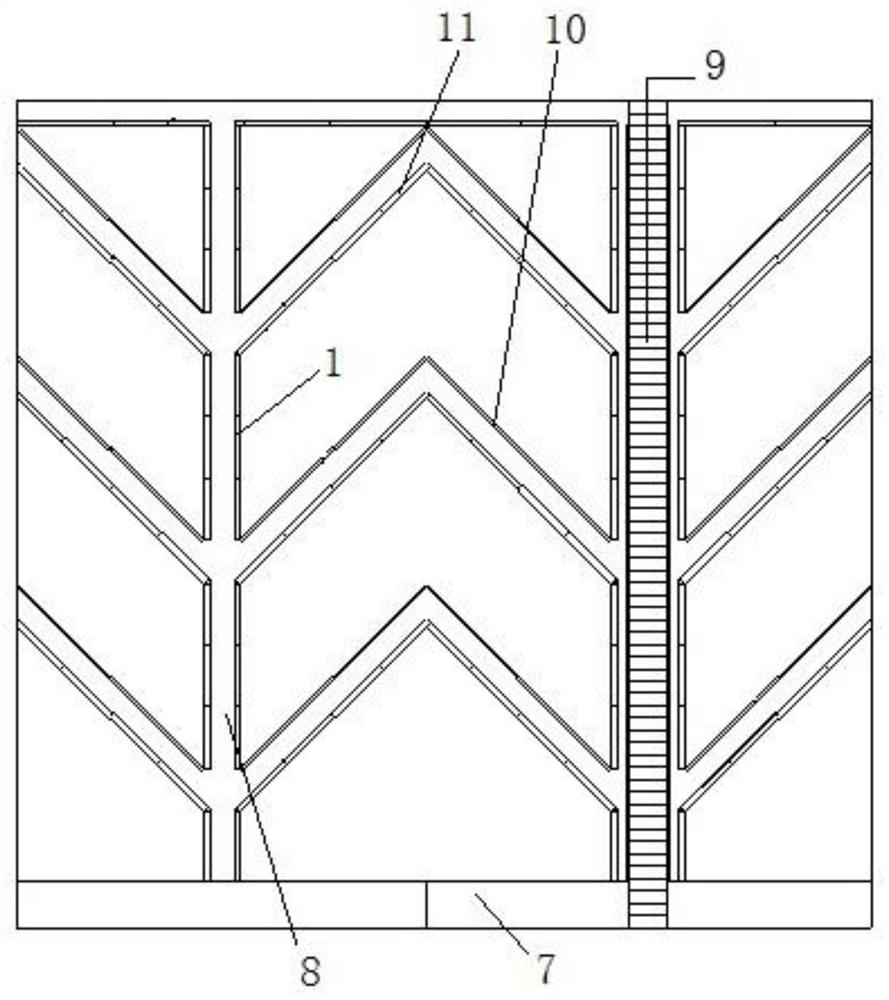

[0062] Such as figure 2 As shown, on the basis of Embodiment 1, the difference lies in that: the shape of the top main frame is herringbone, so that the slope protection units can be assembled into a herringbone frame.

[0063] The slope protection unit is assembled into a herringbone frame through the main frame and the supporting frame, wherein: 6 side prefabricated panels 1 are assembled to form the side straight section of the chevron, 8 top prefabricated panels are assembled to form the top section of the chevron, and 8 The support frame is assembled to be arranged above the top section of the chevron, and is parallel to the top section to form a chevron section.

[0064] Furthermore, the side prefabricated panels 1, the top prefabricated panels 11 and the support frame precast panels 10 are made of cement boards.

Embodiment 3

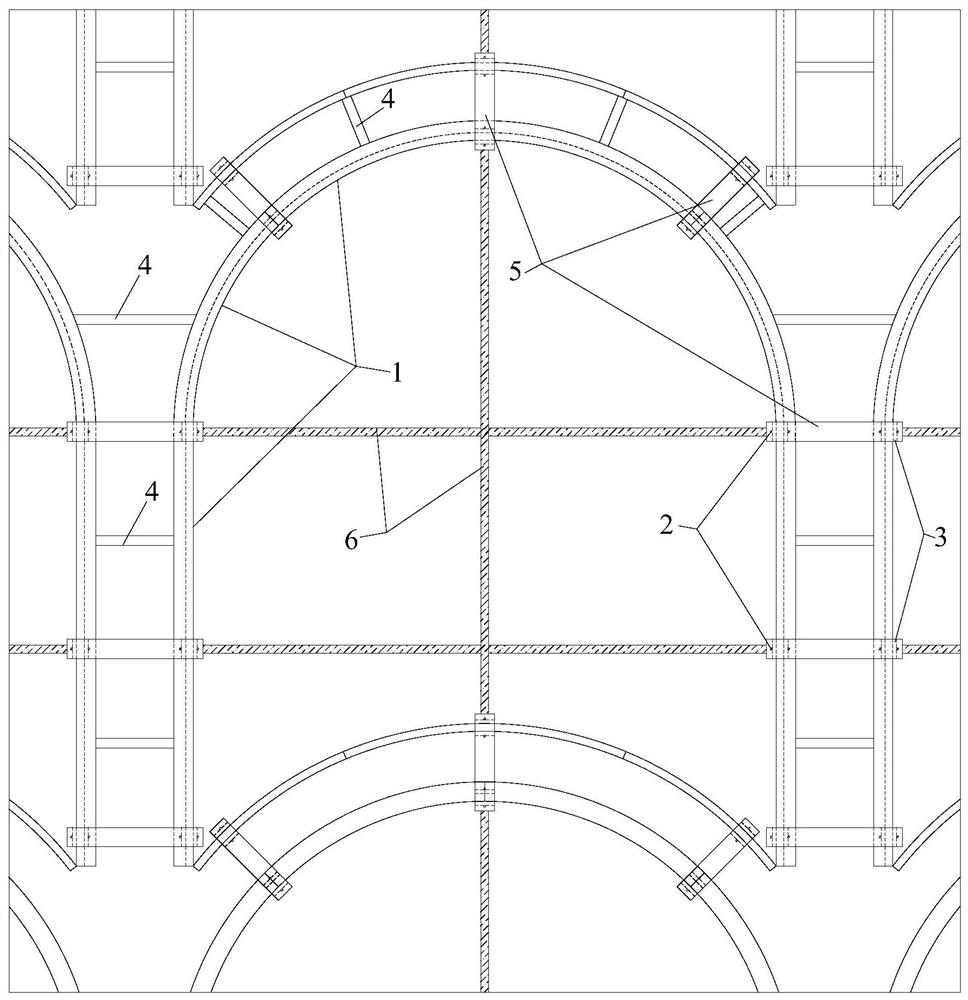

[0066] Such as Figure 6 As shown, a kind of railway slope prefabricated and assembled post-casting skeleton slope protection structure of the present invention comprises a plurality of slope protection units, inspection ladder steps 9, concrete foot protection 7 and post-cast concrete core column 8, and a plurality of slope protection units are as follows: The form of repeated combination extends longitudinally and vertically on the railway slope;

[0067] Each of the slope protection units is composed of a plurality of main skeletons and support frames assembled to form a square, which is used to limit the pouring range of the post-cast concrete core column 8 on the slope, and the main skeleton is composed of a plurality of side prefabricated panels 1 assembled. The two right-angled sides adjacent to the top of the square, the support frame is assembled from a plurality of support frame prefabricated panels 10 to form the two adjacent right-angled sides at the bottom of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com