Fluid-atomizing mechanical nozzle

A mechanical nozzle and fluid technology, applied in mechanical equipment, spraying devices, spraying devices, etc., can solve problems such as poor atomization, flow fluctuation, failure to achieve atomization quality, atomization angle and atomization area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

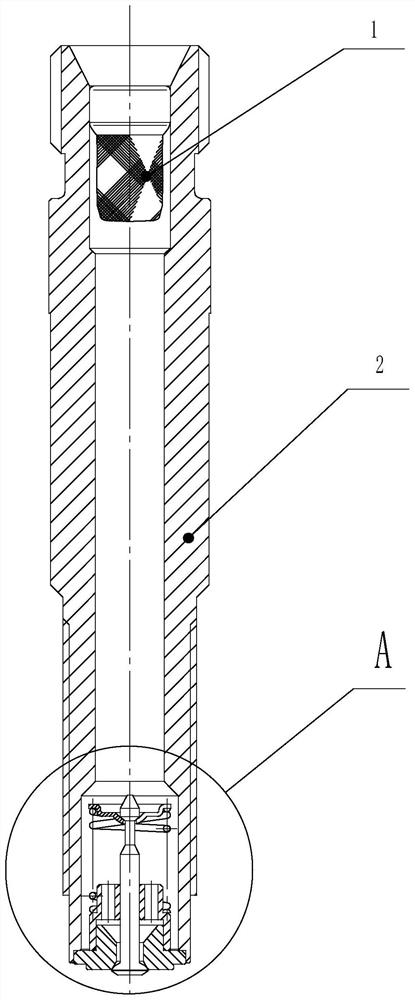

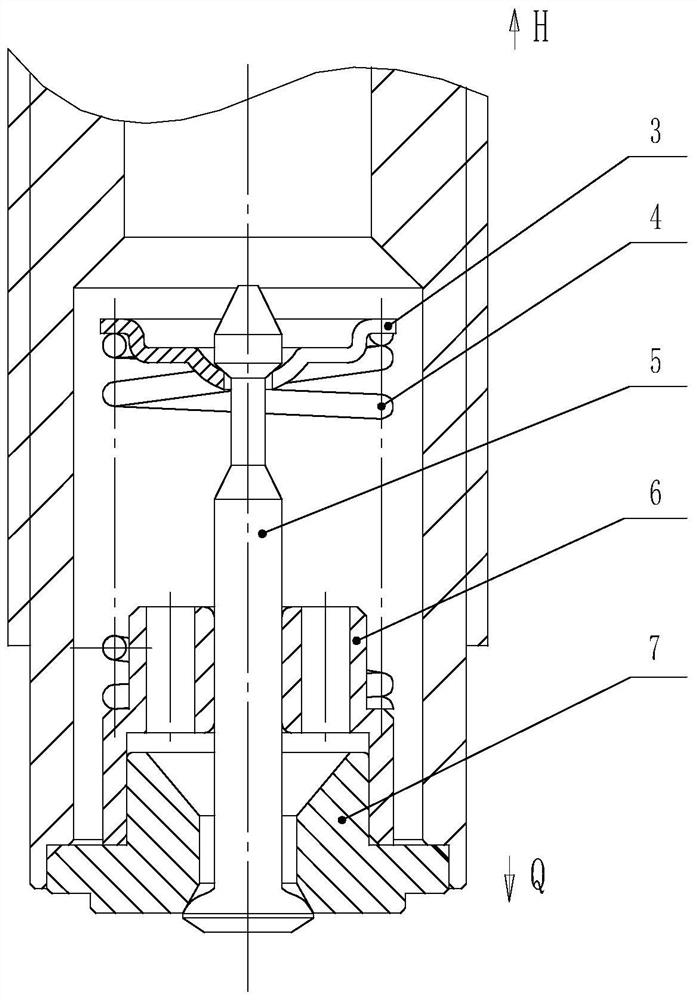

[0056] figure 1Disclosed in is a fluid atomization mechanical nozzle, including a valve body 2 with a fluid input port, a liquid filter 3, a spring 4, a valve needle 5, a swirl seat 6, and a valve seat 7, wherein:

[0057] A metal filter screen 1 is installed in the fluid input port of the valve body 2, and the metal filter screen 1 is a stainless steel filter screen.

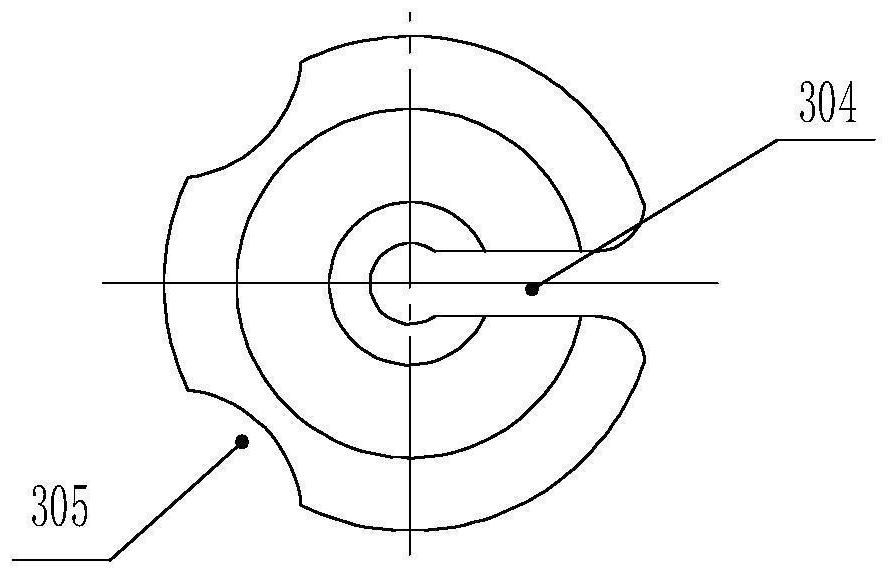

[0058] The valve seat 7 is installed at the front end of the valve body 2, the valve needle 5 is installed in the valve seat 7 and can slide up and down in the valve seat 7, the front end of the valve seat 7 is provided with a swirl chamber I701, and the swirl chamber I701 is Conical surface structure; the front end of the valve needle 5 is provided with an outer spherical structure matching with the swirl chamber I701, and the outer spherical structure at the front end of the valve needle 5 is sealed and matched with the swirl chamber I701 at the front end of the valve seat 7; the valve seat 7 The gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com