Efficient automobile fuel high-pressure pump

A technology for high-pressure pumps and automobiles, which is applied to fuel injection pumps, fuel injection devices, liquid fuel feeders, etc., and can solve problems such as low delivery efficiency, clogged oil supply pipes, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

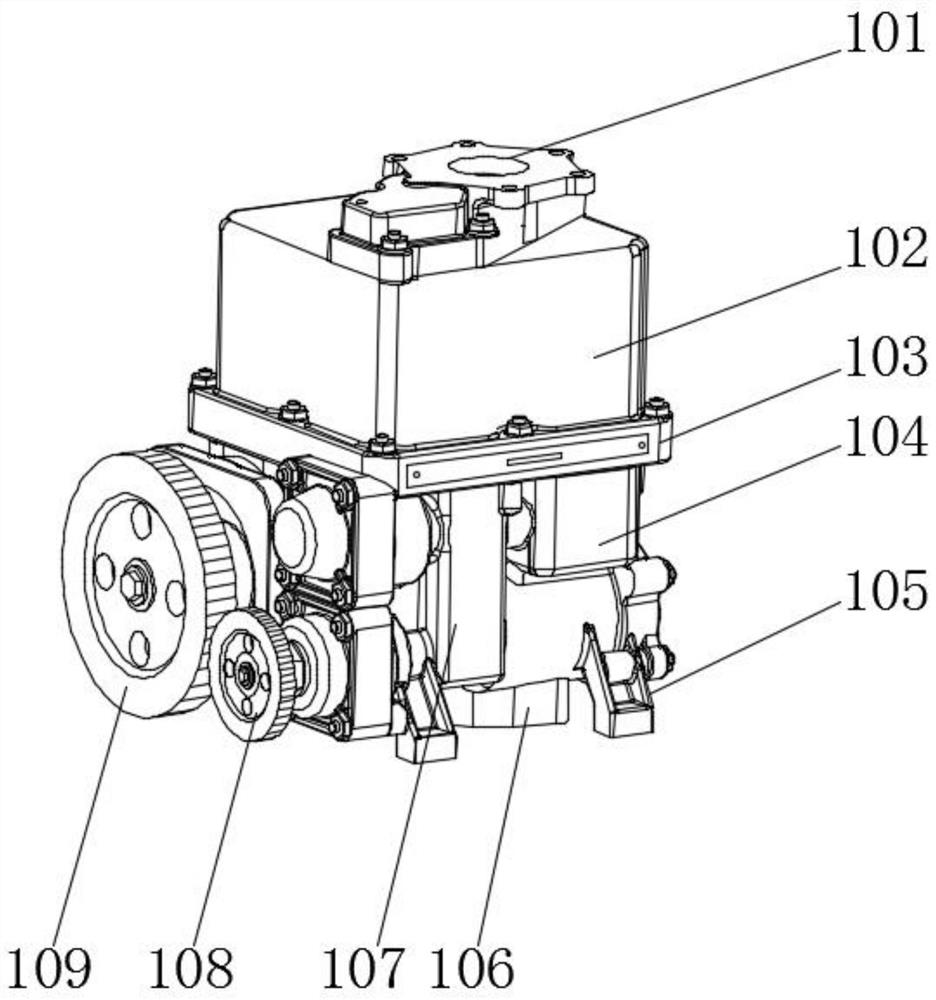

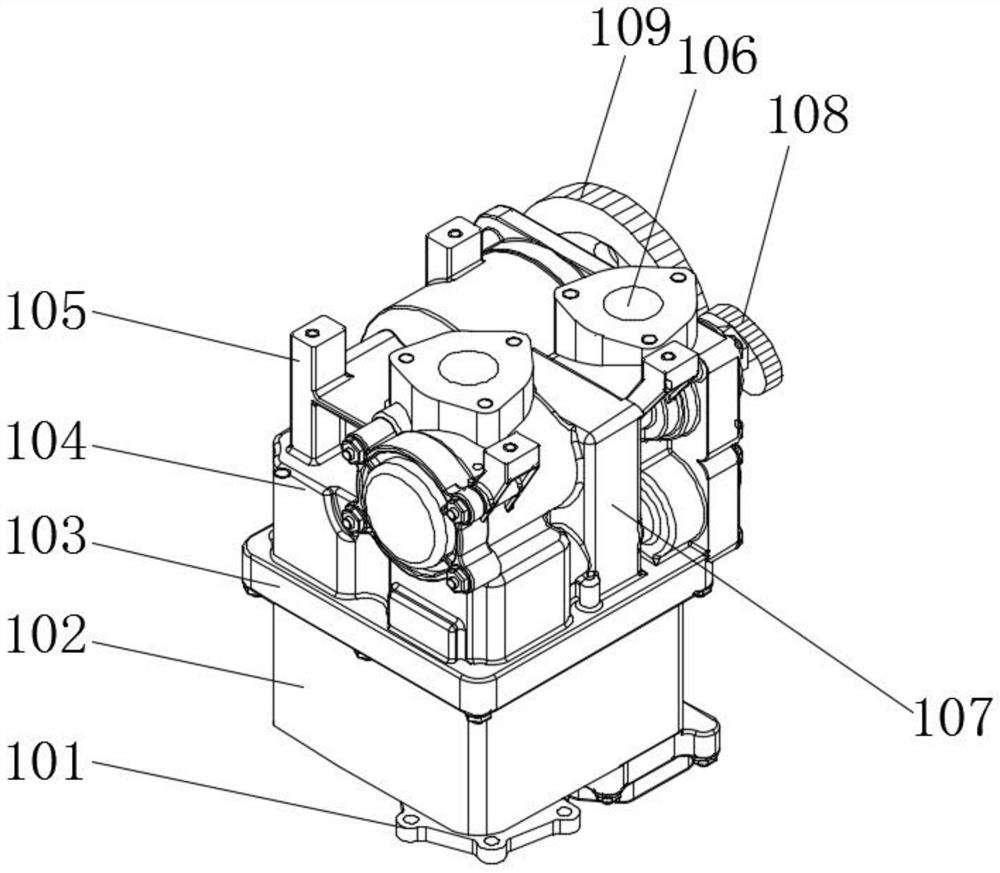

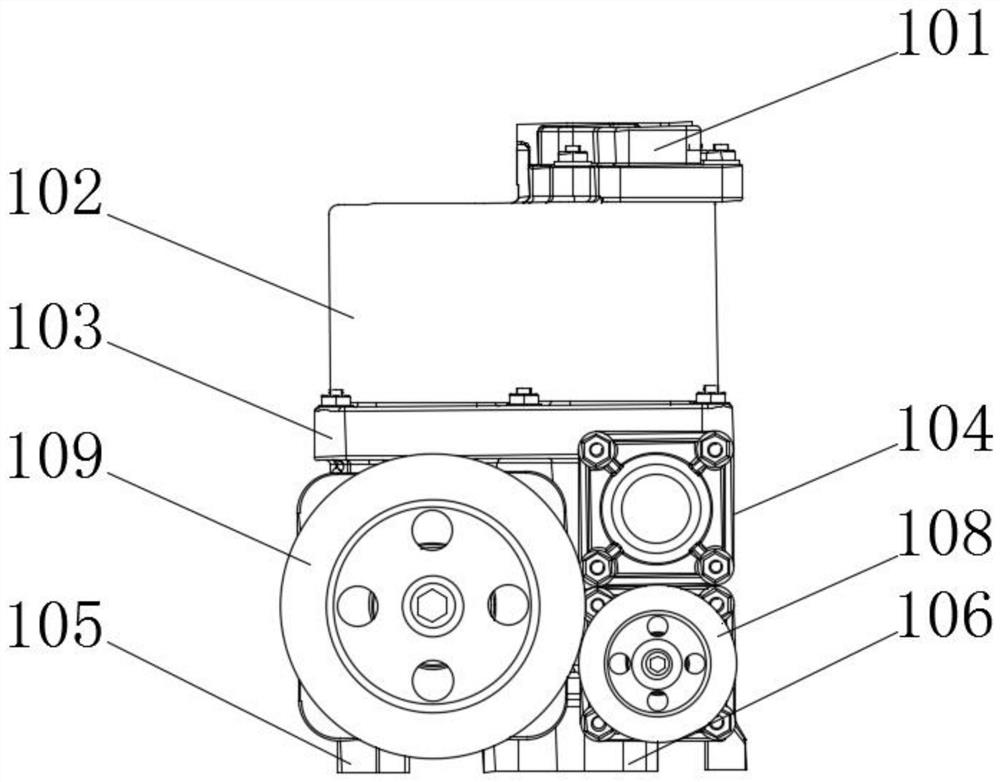

[0037] see Figure 1-11 As shown, this embodiment is a high-efficiency automobile fuel high-pressure pump, including an oil delivery port 101, a delivery adjustment fuel tank 102, a filter box 103, a transmission box 104, a support leg 105, an oil inlet 106, an oil delivery channel 107, The moving gear 108 and the driving gear 109, both ends of the bottom side of the transmission case 104 are provided with oil inlets 106, and support legs 105 are installed at the four corners of the bottom of the transmission case 104. An oil channel 107 is arranged on the side, a driving gear 109 and a driven gear 108 are arranged on one side of the transmission case 104, the driving gear 109 and the driven gear 108 are meshed and connected, and the transmission case 104 is installed on the top There is a filter box 103, the top of the filter box 103 is provided with a conveying adjustment oil tank 102, and the top of the conveying adjustment oil tank 102 is provided with an oil supply port 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com