Deep sampling equipment for geological detection

A sampling equipment and deep-layer technology, applied in the direction of sampling devices, etc., can solve the problems of inconvenient portability, large sampling rod size, and inability to perform soil sampling operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

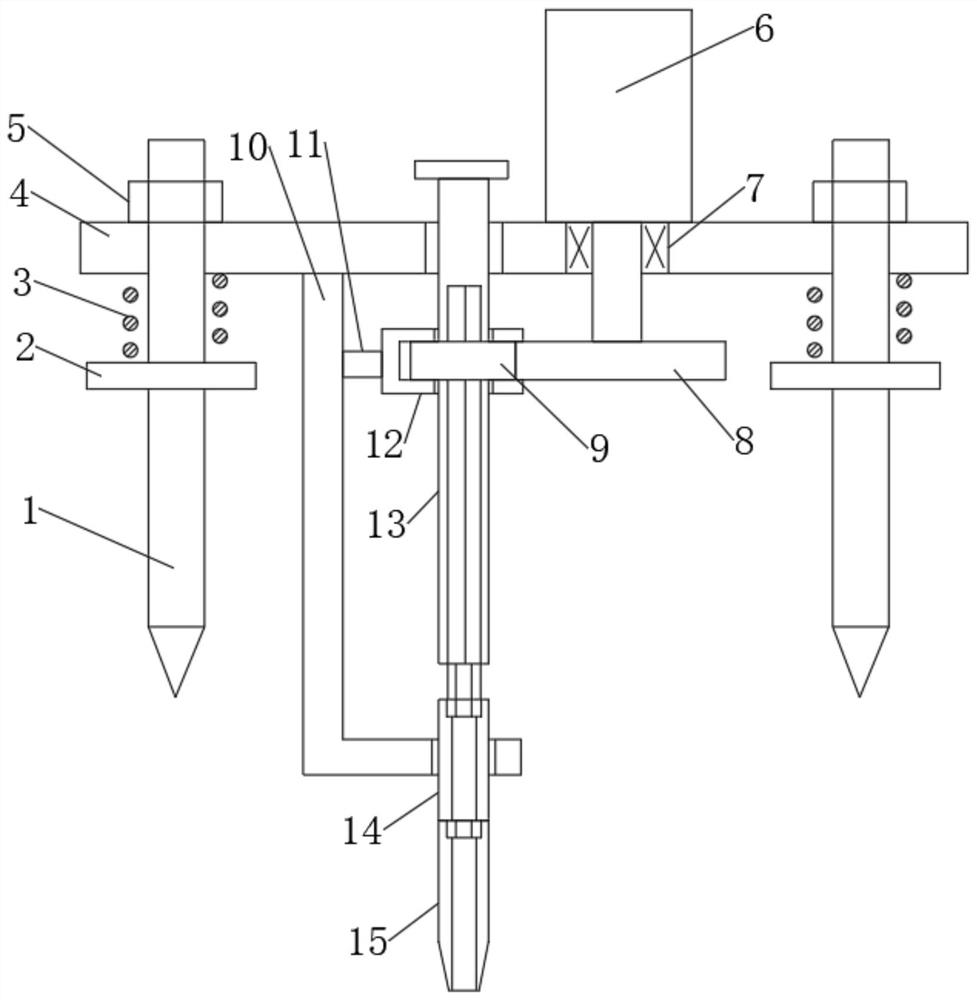

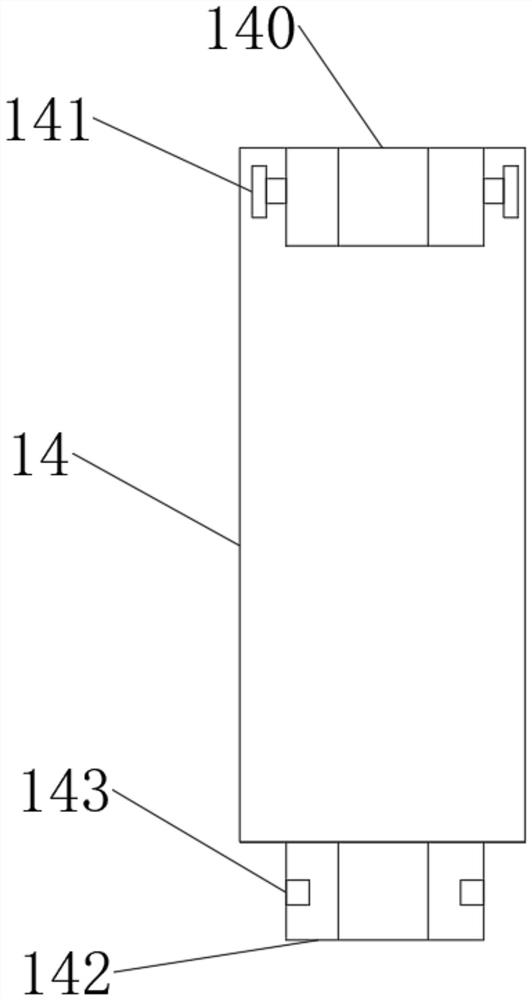

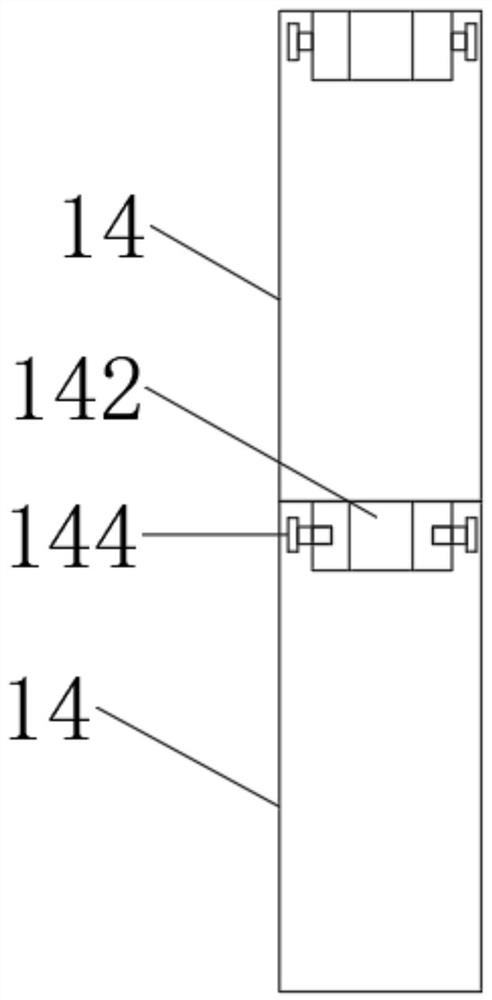

[0028] Such as Figure 1-6 As shown, a kind of deep sampling equipment for geological detection includes a fixed column 1, a step platform 2 is arranged on the fixed column 1, a shock absorbing spring 3 is arranged on the step platform 2, and a Mounting plate 4, described mounting plate 4 is connected with damping spring 3 through lock nut 5, described mounting plate 4 is provided with motor 6, described motor 6 is connected with output shaft, and driving gear 8 is installed on the described output shaft , the driving gear 8 is meshed with the driven gear 9, the driven gear 9 is connected to the limit frame 12, the limit frame 12 is connected to the connecting frame 10 through the connecting column 11, and the connecting frame 10 is set as L-shaped, the driven gear 9 is plugged with a transmission rod 13, the transmission rod 13 is provided with a transmission tooth 130, the top of the transmission rod 13 is provided with a limit block 131, and the transmission rod 13 is conne...

Embodiment 2

[0043] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

[0044] A deep sampling device for geological detection, including all parts in embodiment 1, and also includes:

[0045] Further, the transmission rod 13 is designed to be solid, and the material of the transmission rod 13 is steel.

[0046] Concretely, while the transmission rod 13 is transmitting power to the extension rod 14 and the drill bit 15, the transmission rod 13 will continuously descend. Therefore, the transmission rod 13 is set to be solid, and the material of the transmission rod 13 is selected as steel to further improve the quality of the transmission rod 13 .

[0047] The working principle of the embodiment of the present invention is:

[0048] Such as Figure 1-6 As shown, a deep sampling device for geological detection is assembled according to the diagram.

[0049] After the installation is completed, the drive rod 13 is started to rotate by st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com