Magnetic control shape memory alloy actuator displacement control method

A memory alloy and displacement control technology, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of complex hysteresis dynamic characteristics of magnetically controlled shape memory alloy actuators, restricting applications, and difficulty in achieving satisfactory control by control methods Effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

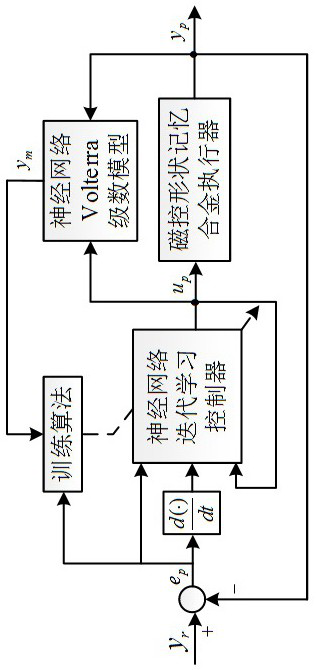

[0050]A method for controlling the displacement of a magnetically controlled shape memory alloy actuator based on neural network iterative learning control provided by the present invention is characterized in that it comprises the following steps:

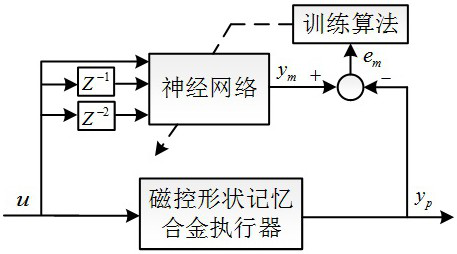

[0051] Step 1: Establish a Volterra series model that can describe the rate-dependent hysteresis nonlinearity of the magnetically controlled shape memory alloy actuator, and use the neural network to construct the kernel function of the Volterra series;

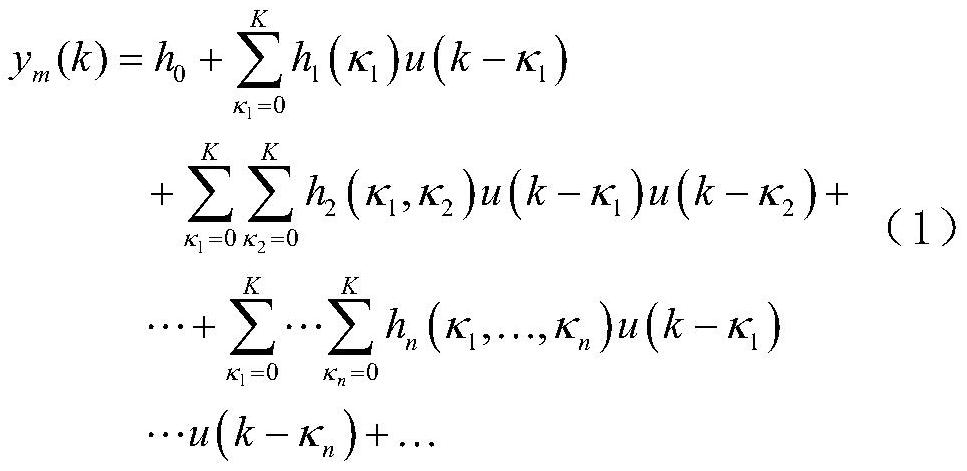

[0052] The expression of the Volterra series model is:

[0053]

[0054] Among them, k=0,1,...,N-1 is the discrete time, N is the expected time length and is a positive integer, n is the order of the model, p is the number of iterations, u p (k) and is the input and output values of the model at the pth iteration, h n (κ 1 ,...,κ n ) and K is the nth order kernel function and memory length of the model, κ n is the memory delay corresponding to the nth item.

[0055] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com