Chip-level LED integrated fluorescent lamp core

A LED chip, chip-level technology, applied in the direction of light source, light source fixing, semiconductor devices of light-emitting elements, etc., can solve problems such as falling off, affecting the luminous efficiency of LED lights, and reducing the service life of LED lights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

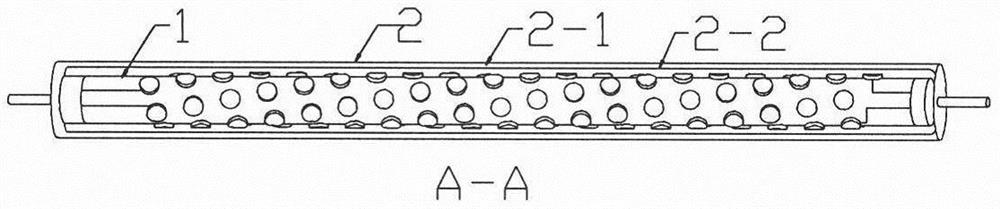

[0024] Such as figure 1 , 2 , shown in 3 and 4: a chip-level LED integrated fluorescent wick, comprising: LED primary light body 1, fluorescent glass tube 2 encapsulating LED primary light body 1; , an electronic circuit 1-2, a terminal 1-3, a conductive wire 1-4, and LED chips 1-5 uniformly distributed on the bracket 1-1; it is characterized in that: the bracket 1-1 has sheet type, tube type, column type, special-shaped various shapes, as the support 1-1 for fixing the LED chip 1-5, its surface is printed with electronic circuits 1-2 and is provided with terminals 1-3 and conductive wires 1-4 that can be connected to an external power supply ; The LED chips 1-5 are evenly distributed on the support 1-1 and connected with the electronic circuit 1-2 to form an overall structure; the fluorescent glass tube 2 has straight tubes, U tubes, spiral tubes, special-shaped tubes, fluorescent The glass tube 2 is manufactured in the following ways:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com