Regenerated adsorption material and preparation method thereof

A technology of adsorption materials and composite adsorption materials, applied in the field of preparation of environmentally friendly materials, can solve the problems of consumption of natural resources, difficulty in improving adsorption efficiency, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

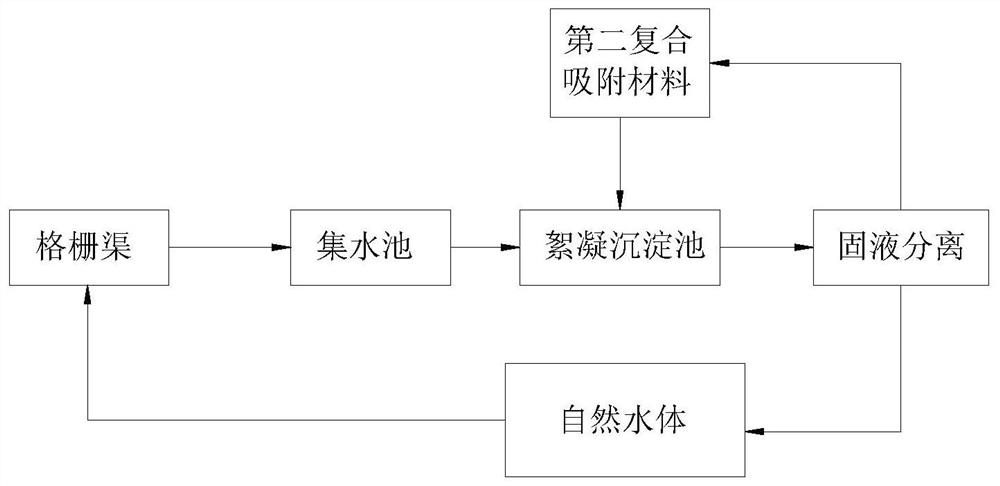

Method used

Image

Examples

preparation example Construction

[0025] Preparation of activated sludge adsorption material: after press-filtering the remaining activated sludge, it is dried in a nitrogen atmosphere to obtain dried sludge; the dried sludge is thermally cracked in a nitrogen atmosphere to obtain activated sludge Adsorption material; the water content of the remaining activated sludge after pressure filtration is 60-80wt%; the drying temperature is 80-200°C, and the time is 10-80min; the temperature of thermal cracking is 500-800°C, and the time is 10-80min.

[0026] The active mud adsorption material is used to adsorb algae and its pollutants in the water body to obtain precipitation, and then the sediment is separated to obtain a mixture containing algae, sludge and active mud adsorption material, and the mixture is dried at 100-200°C for 60- 120min, until the moisture content is not more than 20%; after that, go through anaerobic carbonization at 600-800°C for 60-120min, until the moisture content is not more than 1wt%; put...

Embodiment 1

[0028] After the precipitation material is separated, it is dried in turn. The treatment condition is 200 ° C for 60 minutes; the moisture content of the material after drying treatment is 20 wt %; Oxygen carbonization for 120 minutes, the moisture content of the material after carbonization treatment is less than 1wt%; the water vapor activation treatment is carried out in a muffle furnace, and the treatment process is: put the carbonized material to be activated into the reaction tube of the muffle furnace, and continue Introduce nitrogen into the muffle furnace, and after the air in the tube is exhausted, inject water vapor at 600mL / min, and at the same time raise the temperature to the activation temperature of 810°C at 18°C / min for 60 minutes, and cool down to room temperature at 25°C / min after activation , that is, a regenerated composite adsorbent material is obtained.

Embodiment 2

[0030] After the precipitation material is separated, it is dried in turn. The treatment condition is 100 ° C for 120 minutes; the moisture content of the material after drying treatment is 18 wt %; Oxygen carbonization for 60 minutes, the water content of the material after carbonization treatment is less than 1wt%; the water vapor activation treatment is carried out in a muffle furnace, and the treatment process is: put the carbonized material to be activated into the reaction tube of the muffle furnace, and continue Introduce nitrogen into the muffle furnace, after the air in the tube is exhausted, inject water vapor at 700mL / min, at the same time raise the temperature at 15°C / min to the activation temperature of 800°C for 80 minutes, and cool down to room temperature at 20°C / min after activation , that is, a regenerated composite adsorbent material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com