Double-layer oil tank rotary welding mechanism

A spin welding, double-layer oil tank technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as inability to weld cylindrical weldments, weld fractures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

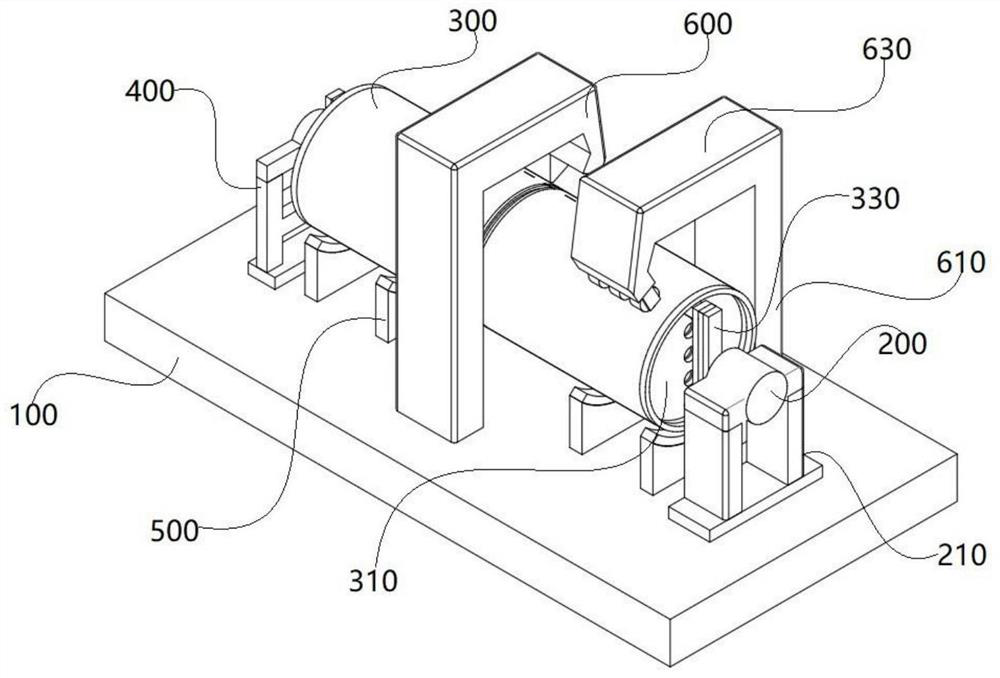

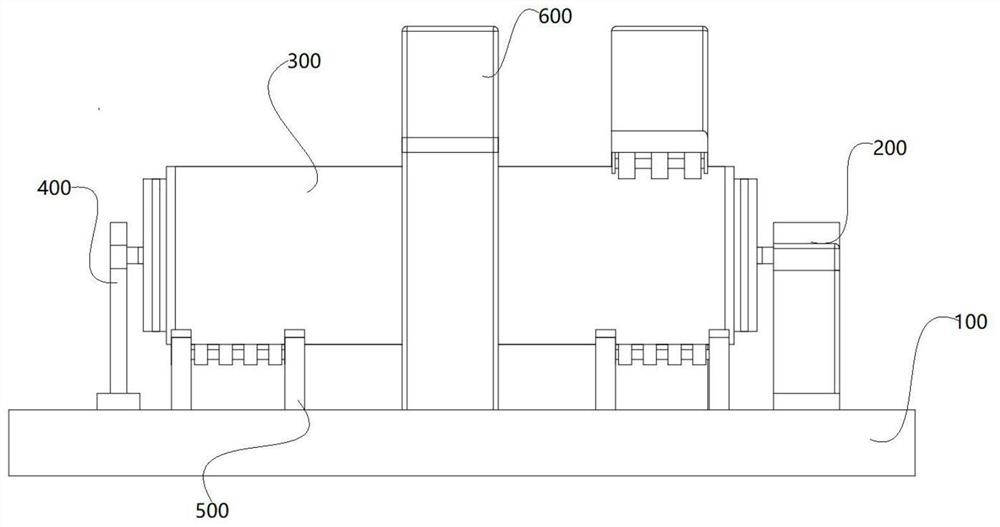

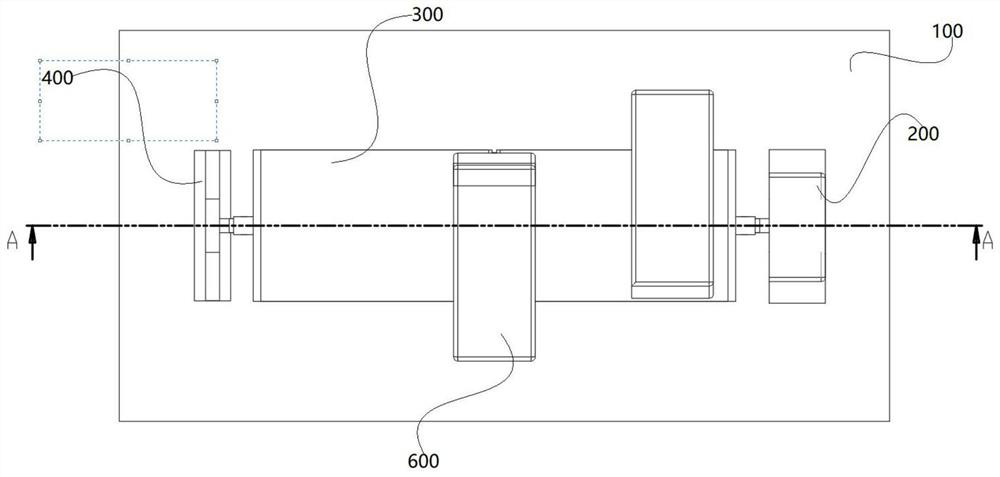

[0023] Please refer to figure 1 As shown in -4, the present invention is a double-layer oil tank rotary welding mechanism, including a fixed plate 100, a motor 200, an oil tank 300, an oil tank rotary table 400, a welding fixture 500 and an electric welding machine 600, and the motor 200 includes a motor body and The motor bracket 210, the lower surface of the motor bracket 210 is welded to the upper surface of the fixed plate 100, the motor body one surface is connected with the motor bracket 210 through threaded screw holes, the oil tank 300 includes the oil tank body and the rotating tray 310, the oil tank body is a hollow structure, Several rotating trays 310 are installed inside the oil tank body, the lower surface of the oil tank rotating table 400 is welded to the upper surface of the fixed plate 100, the lower surface of the fixed plate 100 is provided with a plurality of first installation holes, and the lower surface of the plurality of welding fixtures 500 is respect...

Embodiment 2

[0030] Please refer to figure 1 As shown in -4, the present invention is a double-layer oil tank rotary welding mechanism, wherein the model of the motor 200 is Y2. Two fixed rods 320 are positioned between the trays 310 to ensure that the two oil tanks 300 to be welded remain relatively still during the welding process. During the welding process, the motor 200 drives the oil tank 300 to rotate, and the electric welding machine 600 follows the circular weld seam Welding is performed, and the electrode 630 and the oil tank 300 are kept in a connected state through the provided conductive wheel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com