Processing equipment for quickly assembling pipe and flange

A technology for processing equipment and pipe fittings, which is applied in the field of processing equipment for rapid assembly of pipe fittings and flanges, can solve the problems of occupying installation and construction time, unfavorable pipe fitting installation, time-consuming and labor-intensive, etc., to speed up the installation progress, and the structure is simple and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

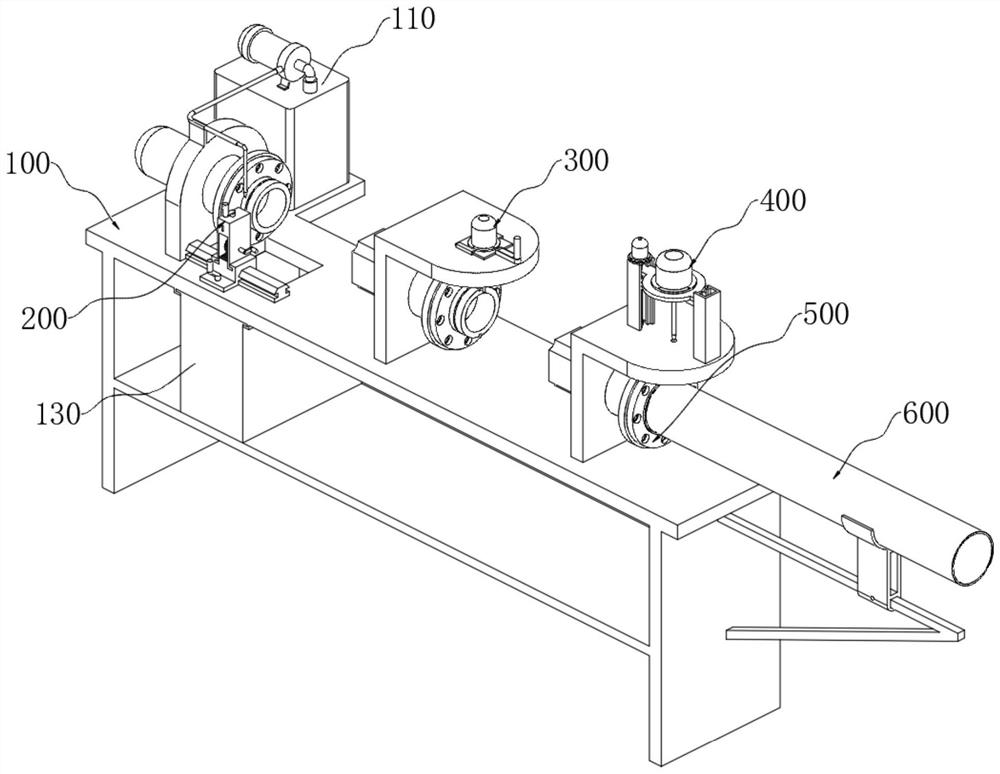

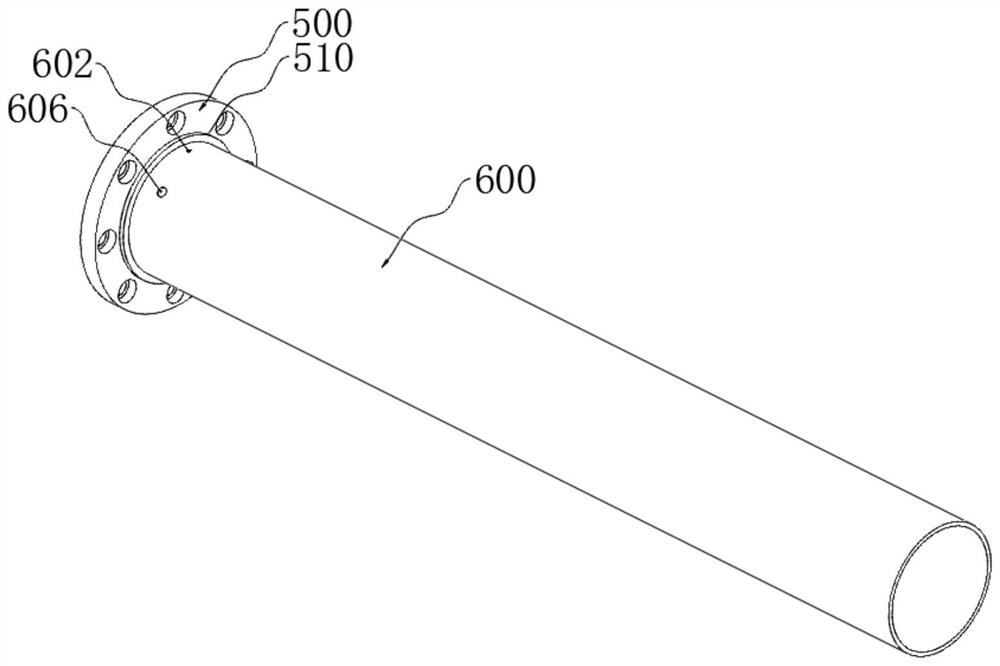

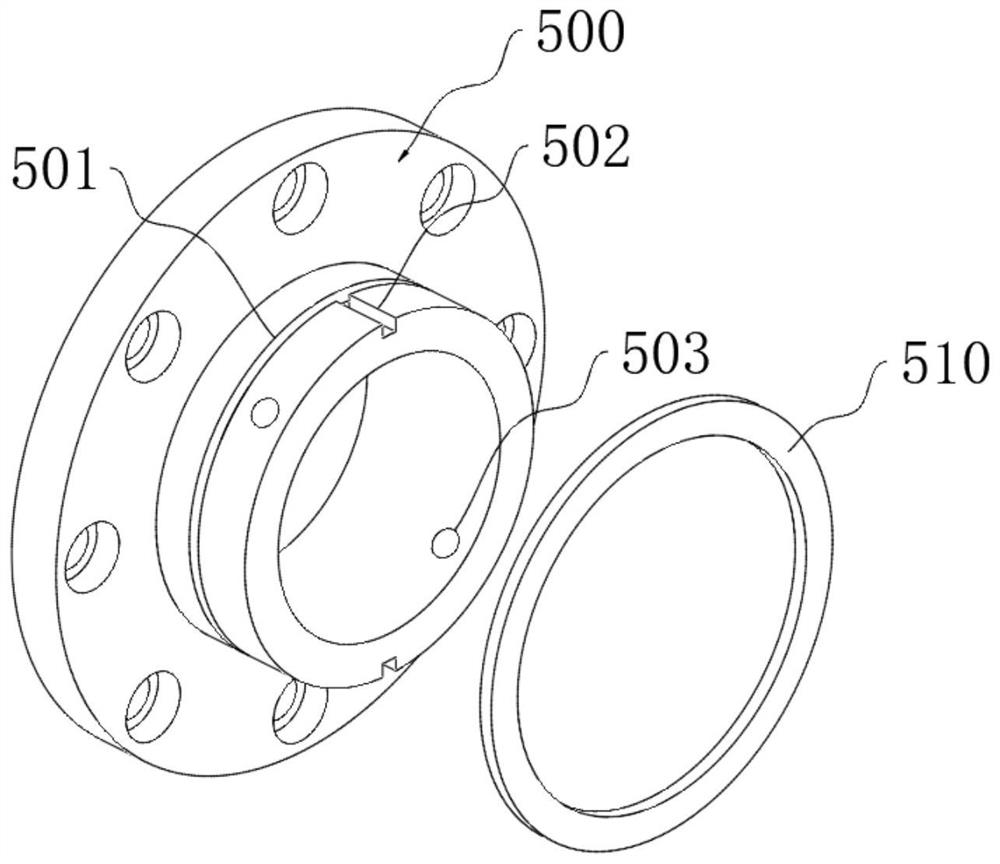

[0064] Such as figure 1 , Figure 5-Figure 11 As shown, the present invention provides a processing equipment capable of fast assembly of pipe fittings and flanges, including a processing table 100, the top surface of the processing table 100 is sequentially fixed with a slotting seat 101, a milling slot seat 140 and a drilling hole from left to right. Seat 150. On the right side of the grooving seat 101 and on the processing table 100, there is a discharge port 104, which is used to let the turning material fall down and avoid accumulation on the processing table 100. A chip box 130 is installed directly below the discharge port 104 for collecting the turning material falling from the discharge port 104 for centralized processing. A grooving mechanism 200 is installed on the grooving seat 101, and the grooving mechanism 200 includes a grooving motor 210 installed in the center of the left side of the grooving seat 101, which is a geared motor, and its name is to provide a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com