Multi-layer small-spacing container

A small-pitch, container technology, applied in the field of machinery, can solve problems such as easy decoupling, small number of products, and increased transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

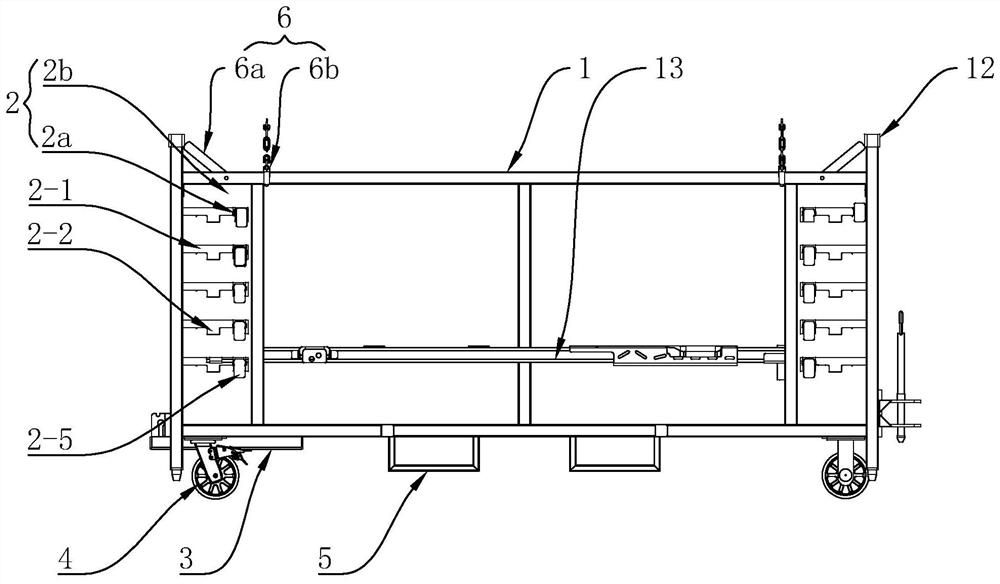

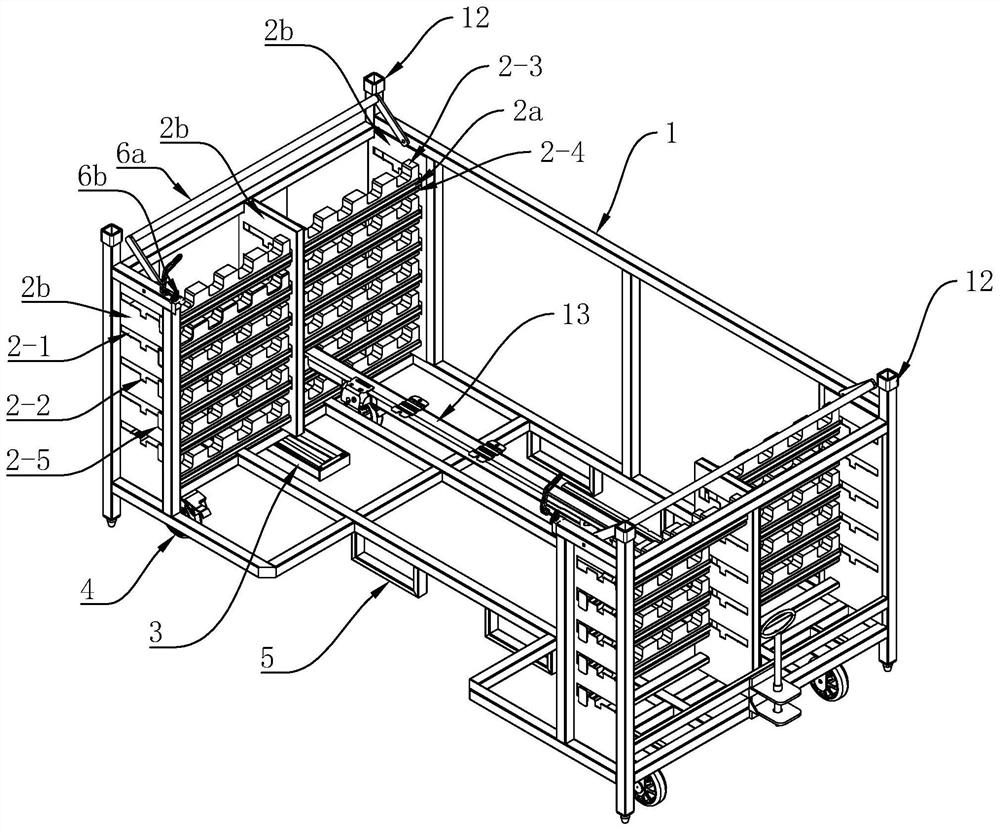

[0041] Such as figure 1 with 2 Shown: a multi-layer small-pitch container, which is composed of a frame 1, a limit fixing device 2 arranged on both sides of the frame 1, and a traction device 3 hidden and fixed at the bottom of the frame 1; the frame 1 There are two limiting and fixing devices 2 on both sides respectively. The bottom of the frame 1 is provided with rollers 4 and positioning rings 5 for forklift transfer;

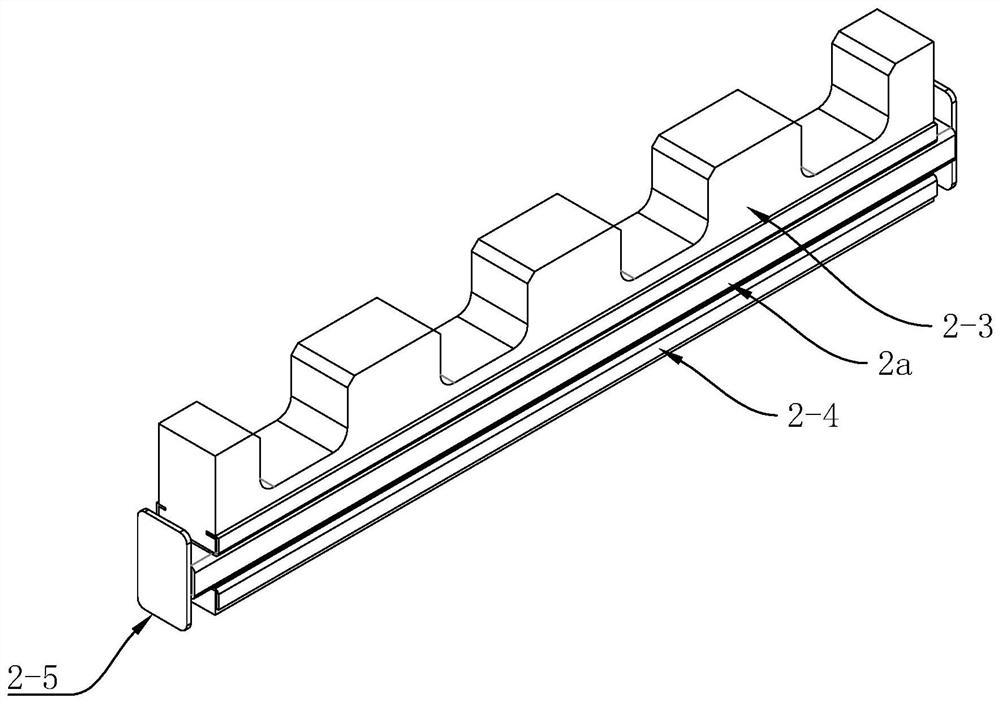

[0042] Such as figure 1 with 2 Shown in and 3: the position-limiting and fixing device 2 is made up of a multi-layer compression beam 2a arranged in parallel and a support plate 2b arranged at both ends of the compression beam 2a, and the support plate 2b is provided with a multi-layer parallel arrangement. Guide groove 2-1, the two ends of the pressing beam 2a are respectively arranged in the guide groove 2-1 on the corresponding side and the corresponding layer and limit sliding, and the two ends of the pressing beam 2a extend into the guide groove 2- ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com