Modular PRB repair method with environmental risk management and control function

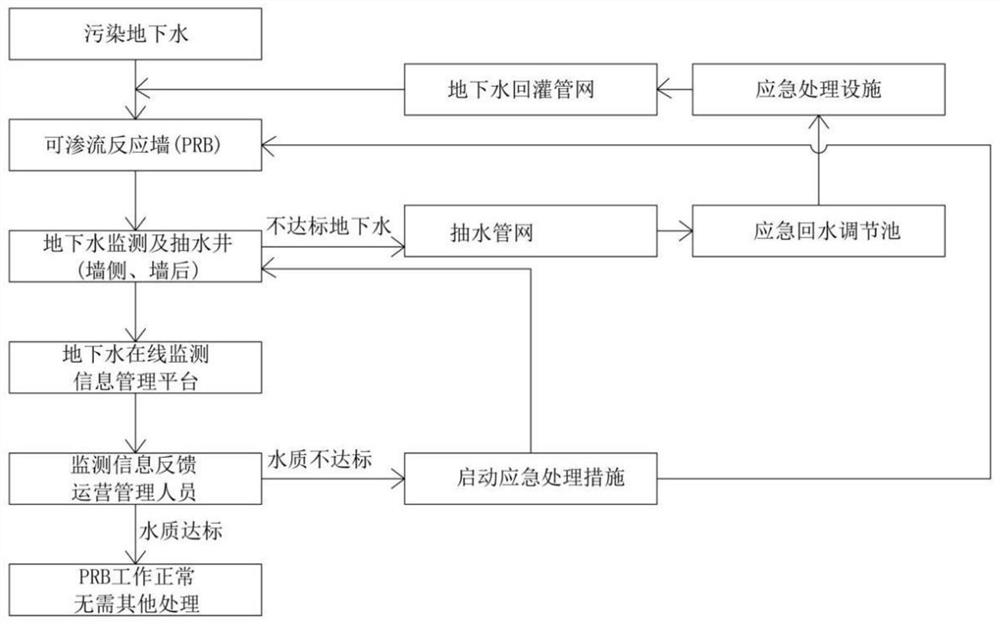

A technology for environmental risks and restoration methods, applied in chemical instruments and methods, water treatment parameter control, control/manipulation systems, etc., can solve problems such as replacement of reaction medium, inability to ensure groundwater purification, and limited capacity of permeable reaction wall media.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention belongs to the technical field of groundwater pollution restoration, and in particular relates to a modularized PRB restoration method with environmental risk management and control functions.

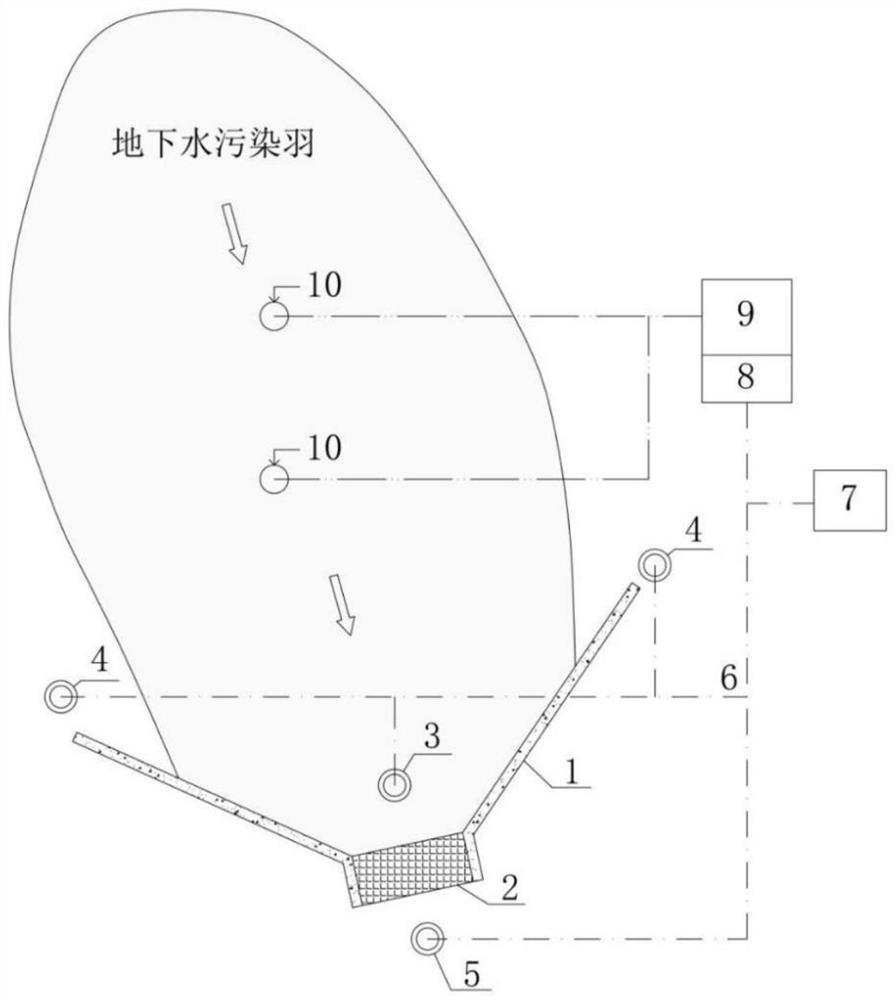

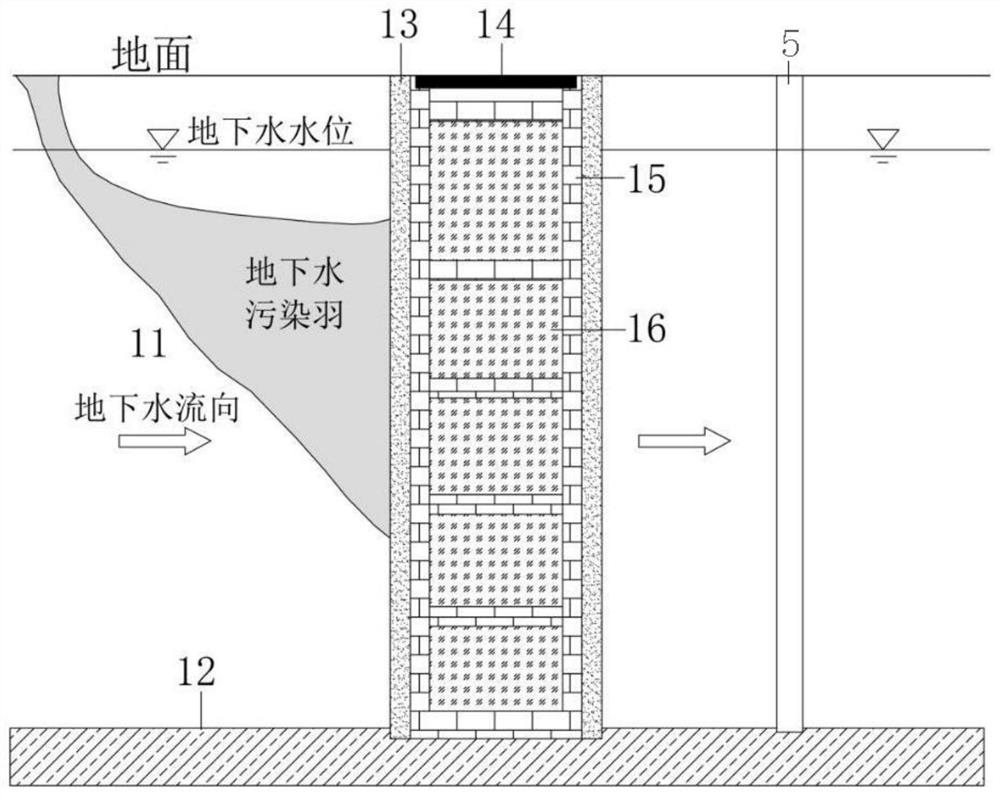

[0035]The site treated by the embodiments of the present invention is a metal electroplating factory site with a production history of more than 30 years. The stratum structure of the electroplating processing plant site: 0-3m is clay fine sand, the permeability coefficient is 0.5m / d; 3-8m is fine sand, the permeability coefficient is 1.5m / d; below 8m is silty clay, the permeability coefficient is 0.05m / d The groundwater on the site mainly exists in the fine sand layer, with a buried depth of about 1m and an annual variation of the groundwater level of about 1m; the groundwater flows from the site from north to south, and finally discharges into a river about 80m away from the south side; the groundwater is detected to exceed the standard Chromate (500-5000μg / L) an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com