Efficient controllable sewage treatment equipment for factory

A sewage treatment equipment and high-efficiency technology, applied in water/sewage treatment equipment, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of reduced aeration efficiency, unqualified batches of engineering dye products, and interference with water circulation. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

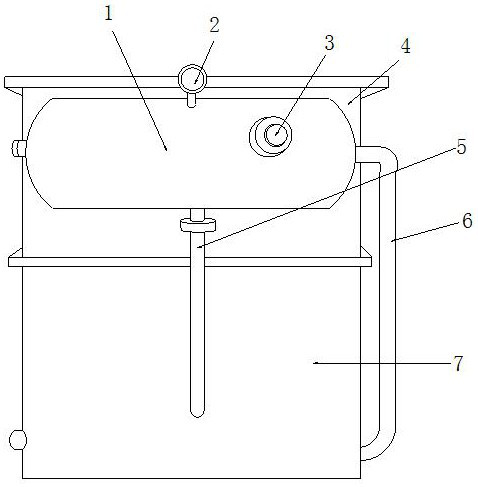

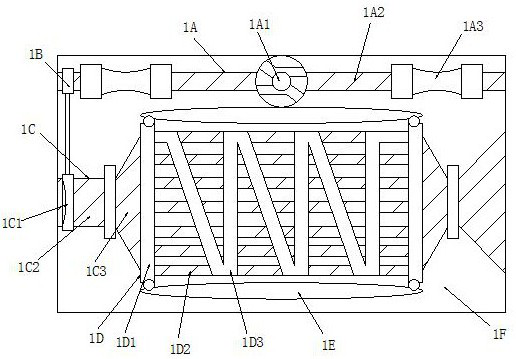

[0032] see Figure 1-Figure 6, the present invention provides an efficient and controllable sewage treatment equipment in a factory, the structure of which includes: a star-shot aeration tube cylinder 1, a pressure gauge 2, a plunger seat cap 3, a purification tank 4, a pressure discharge pipe 5, a diversion pipe 6, Sedimentation tank 7, the star-shot aeration tube cylinder 1 is nested on the front side of the purification tank 4 and is on the same level, the pressure discharge pipe 5 is inserted under the bottom of the middle section of the star-shot aeration tube cylinder 1 and mutually vertical, the star-shot aeration tube cylinder 1 is welded together with the plunger seat cap 3, the pressure gauge 2 is inserted on the top of the star-shot aeration tube cylinder 1 and is perpendicular to each other, the star-shot aeration tube The cylinder 1 communicates with the sedimentation tank 7 through the guide pipe 6. The purification tank 4 is nested on the top of the sedimentatio...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a kind of high-efficiency and controllable sewage treatment equipment in factories, other aspects are the same as in Embodiment 1, the difference is:

[0040] see figure 2 , the star beam pipe frame 1D is composed of a tube converging plate 1D1, an aeration thin tube 1D2, and a ventilation pipe folding frame 1D3, and two tube converging plates 1D1 are respectively nested in two or more The left and right sides of the thin aeration tube 1D2, the thin aeration tube 1D2 is welded together with the air pipe folding frame 1D3 and penetrates each other, and the air pipe folding frame 1D3 is inserted through the small aeration tube 1D2 to form a star-like flow bed interspersed The operation effect of the connection of the pipeline for oxidation, aeration and water purification.

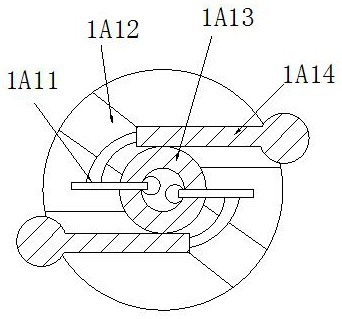

[0041] see Figure 6 , the tube converging disc 1D1 is composed of a baffle frame 1D11, a tube frame 1D12, an aeration outlet 1D13, and a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com