Micro-power sewage treatment equipment with improved decomposition speed

A technology of sewage treatment equipment and decomposition rate, which is applied in water/sewage treatment equipment, water/sewage treatment, water/sewage multi-stage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

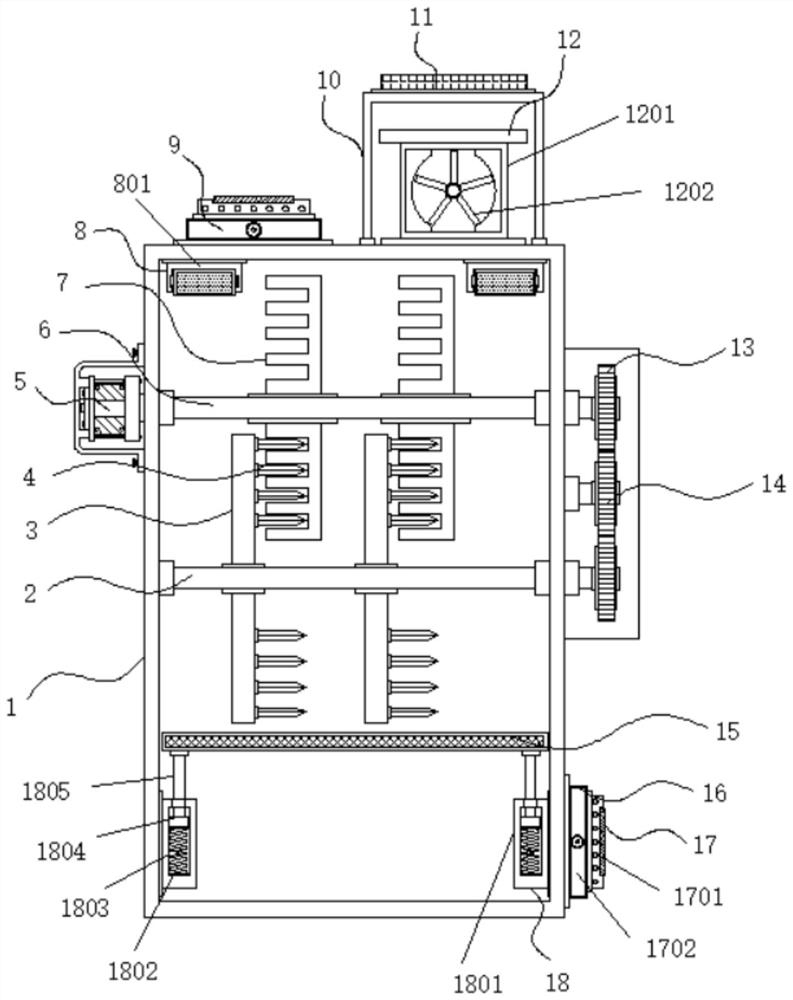

[0035] Example 1: See Figure 1-6 , a kind of micro-power sewage treatment equipment with improved decomposition speed, comprising a treatment tank 1 and a water inlet 9, the top of the treatment tank 1 is provided with an adsorption purification structure 8, and one side of the top of the treatment tank 1 is provided with a water inlet 9, the treatment tank The other side of the top of 1 is provided with a quantitative drug feeding mechanism 12, one end of the quantitative drug feeding mechanism 12 is fixedly connected with a bracket 10, the top of the bracket 10 is provided with a solar panel 11, and the bottom end of one side of the treatment tank 1 is provided with a water outlet 16 , the top of the water inlet 9 and one side of the water outlet 16 are provided with a splicing structure 17, the inside of the treatment tank 1 is provided with a filter residue screen 15 near the bottom, and the bottom end of the filter residue screen 15 is provided with a buffer protection st...

Embodiment 2

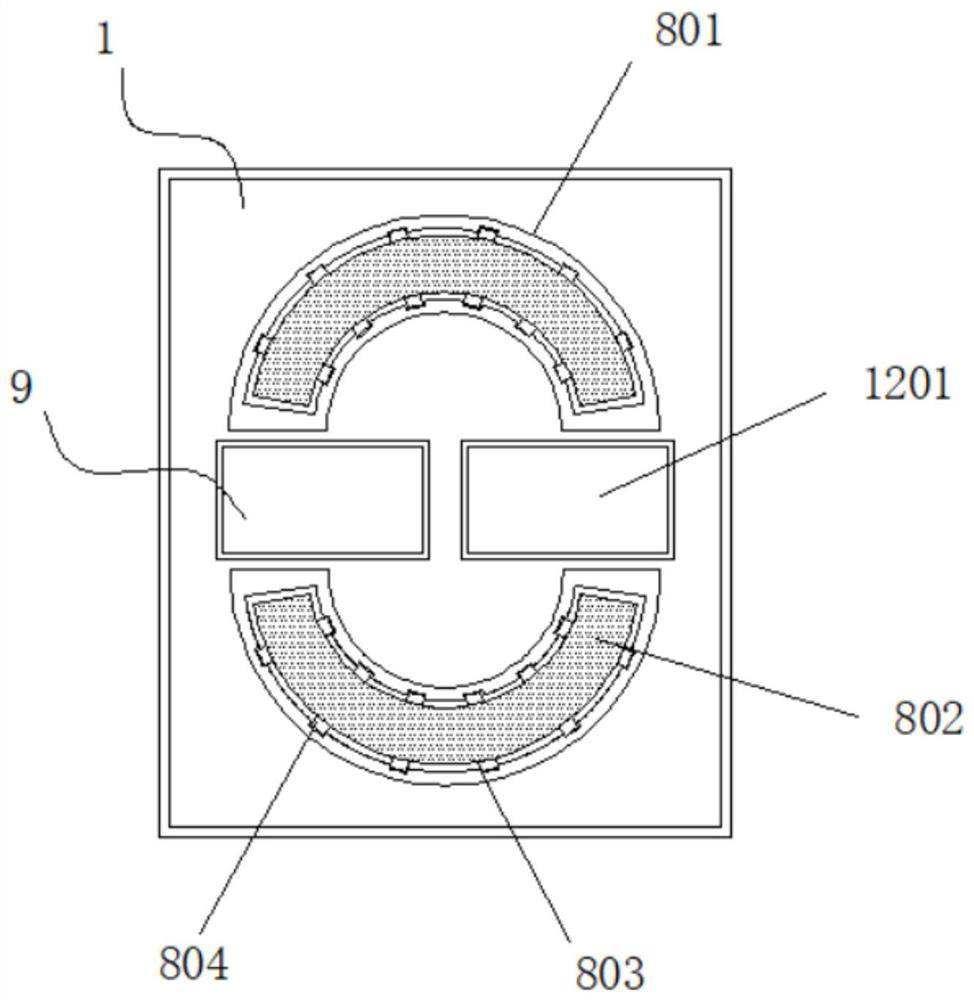

[0040] Embodiment 2: adsorption purification structure 8 is made up of fixed cover 801, activated carbon net 802, draw-in groove 803 and block 804, and fixed cover 801 is respectively fixedly connected to the two ends of the inner top of processing tank 1, and the inner side wall of fixed cover 801 is uniform A card slot 803 is provided, an activated carbon net 802 is provided inside the fixed cover 801, and a card block 804 is evenly provided outside the activated carbon net 802;

[0041] The card block 804 is embedded in the card slot 803, and the card slot 803 is engaged with the card block 804;

[0042] Specifically, such as figure 1 with figure 2 As shown, the adsorption of the activated carbon net 802 can be used to absorb and purify the odor emitted from the sewage, thereby protecting the surrounding environment. At the same time, the card slot 803 and the block 804 can facilitate the disassembly and replacement of the activated carbon net 802, and the operation is si...

Embodiment 3

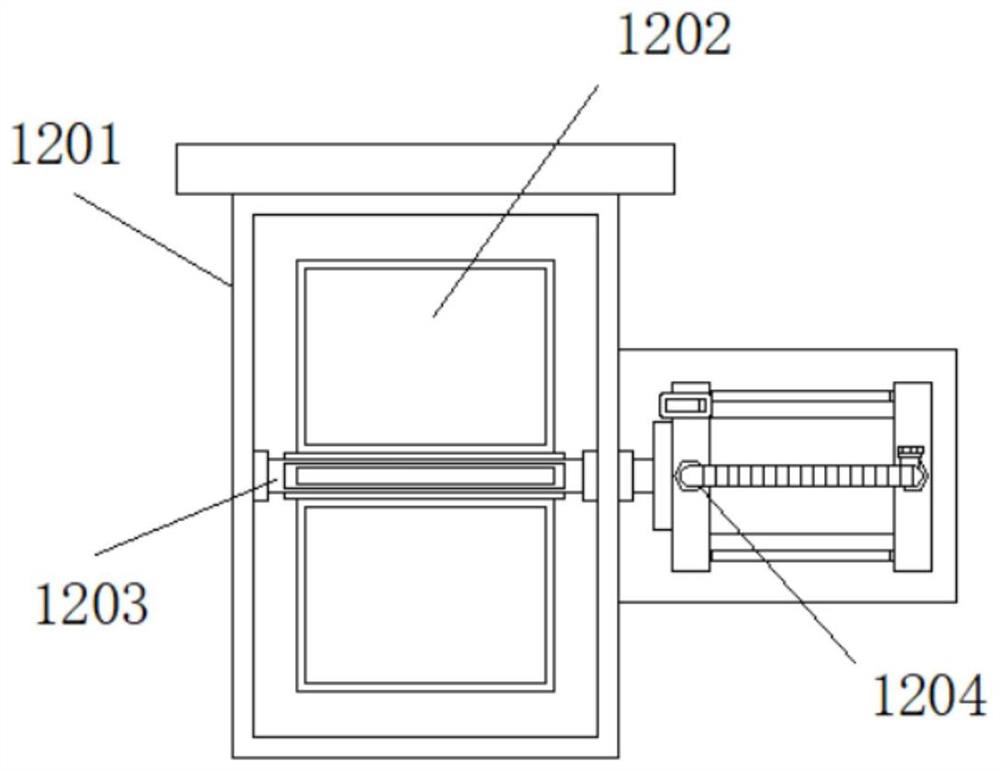

[0043] Embodiment 3: Quantitative drug feeding mechanism 12 is made up of drug inlet 1201, quantitative sheet 1202, quantitative shaft 1203 and driving motor 1204, and drug inlet 1201 is fixedly connected to the side of processing tank 1 top, two inside of drug inlet 1201 A quantitative axis 1203 is movably connected between the ends, and the outside of the quantitative axis 1203 is evenly and fixedly connected with a quantitative sheet 1202, and the driving motor 1204 is fixedly connected to the rear end of the drug inlet 1201, and the model of the driving motor 1204 can be Y90L-2;

[0044] Quantitative sheets 1202 are arranged at equal intervals outside the quantitative axis 1203;

[0045] Specifically, such as figure 1 with image 3 As shown, start the driving motor 1204, the driving motor 1204 drives the quantitative shaft 1203 to rotate, the quantitative shaft 1203 drives the quantitative tablet 1202 to turn over at a constant speed, and quantitatively turns the medicine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com