Construction waste recycling method

A technology of construction waste and recycling methods, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as ineffective utilization and waste of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

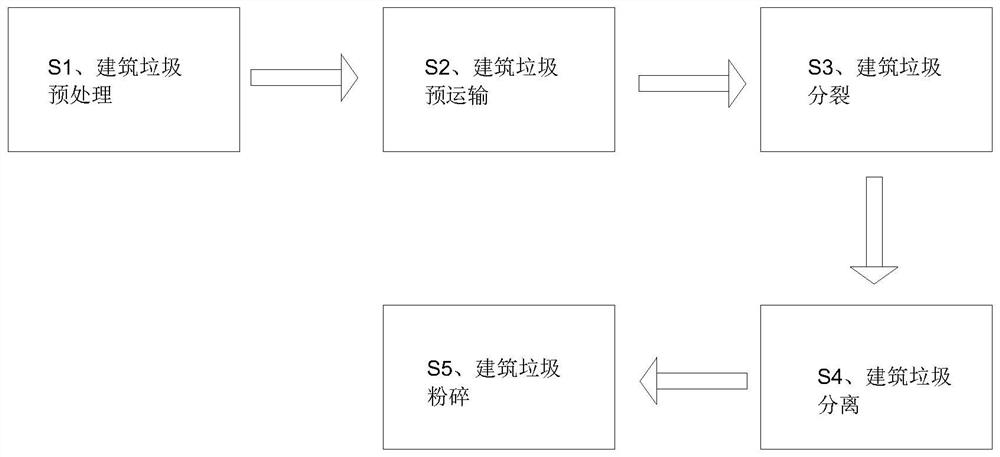

[0024] A method for recycling construction waste, the specific pretreatment method is as follows:

[0025] S1. Construction waste pretreatment: Manually pile up construction waste on the ground;

[0026] S2. Construction waste transportation: the construction waste after step S1 is transported to the feeding port by an excavator;

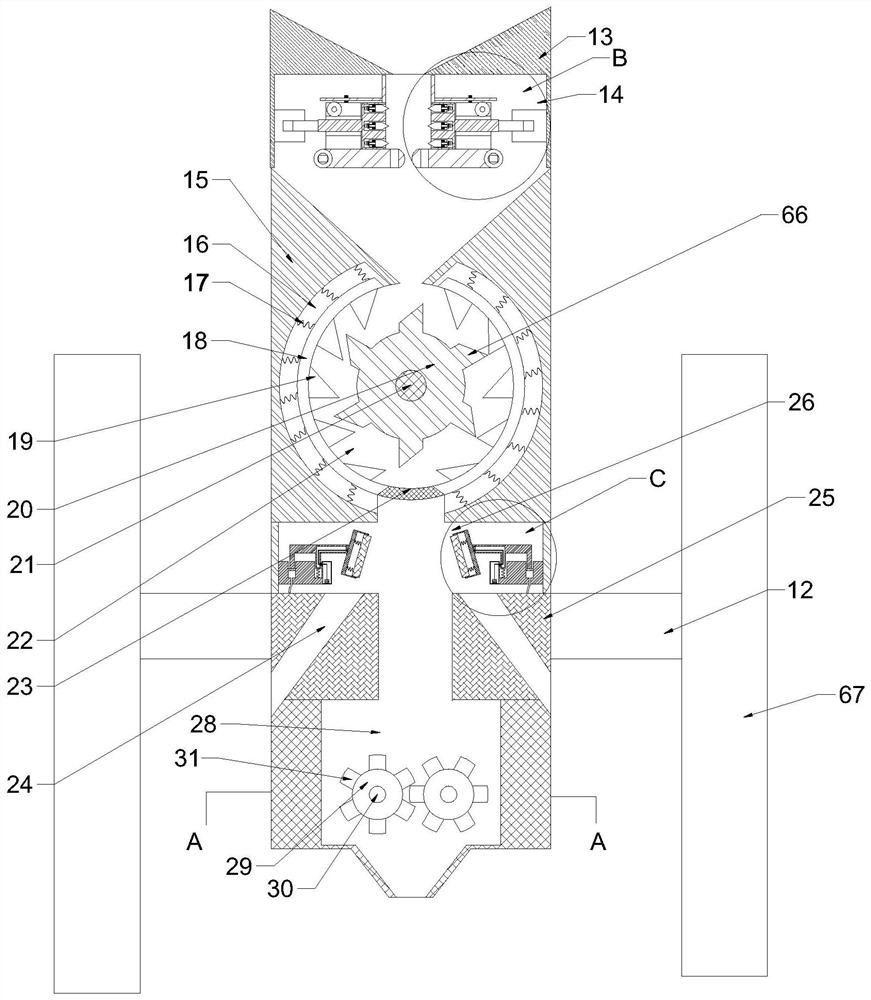

[0027] S3. Construction waste splitting: The construction waste transported to the feeding port through S2 enters the splitting device in turn, and after being split by the splitting device, the split construction waste is fed to the separating device;

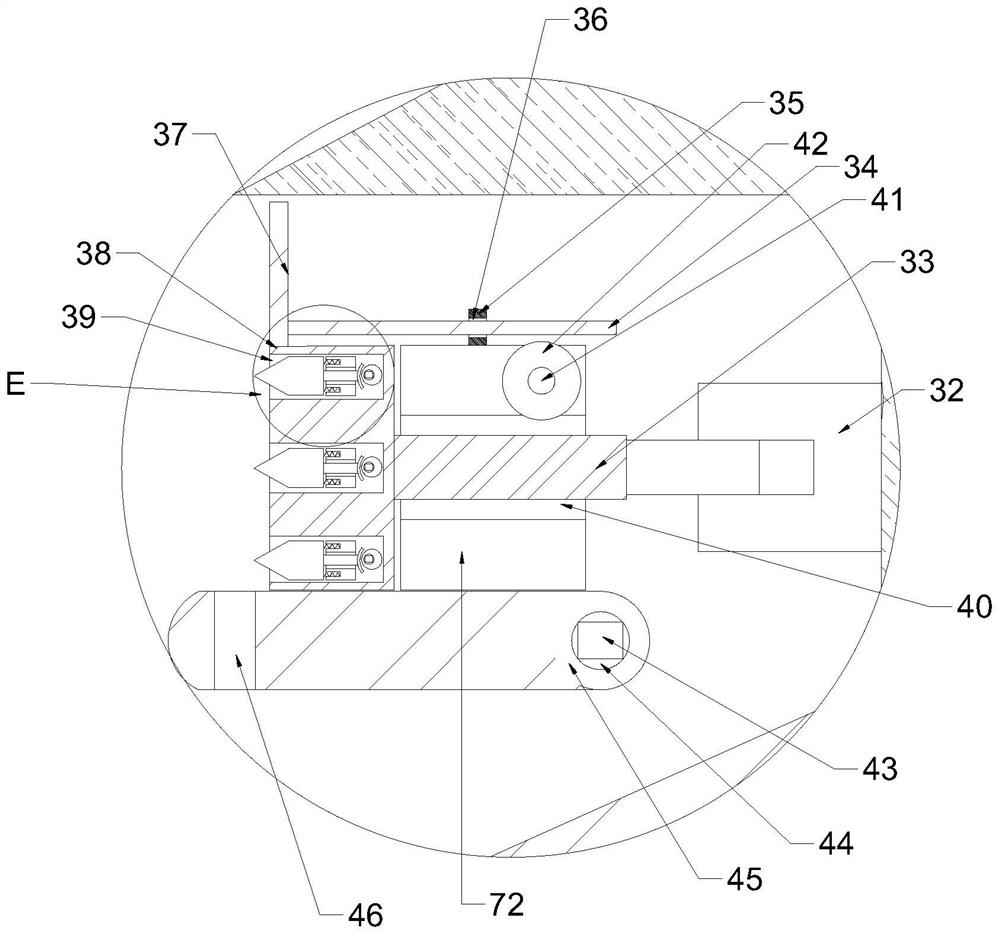

[0028] S4. Separation of construction waste: after passing through the S3 splitting device, the construction waste enters the separation device by its own gravity. After the separation device splits the split construction waste for the second time, the metal and cement blocks in the construction waste are separated, and the The cement waste in the construction waste enters the crushing device;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com