Ultra-large deflection flat coil without ferrite core

A ferrite core, deflection plane technology, applied in the direction of electrode devices and related components, can solve problems such as temperature rise, increase in ferrite core loss, and deterioration of core performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0007] In order to better understand the technical solution of the present invention, further description will be made below in conjunction with the accompanying drawings.

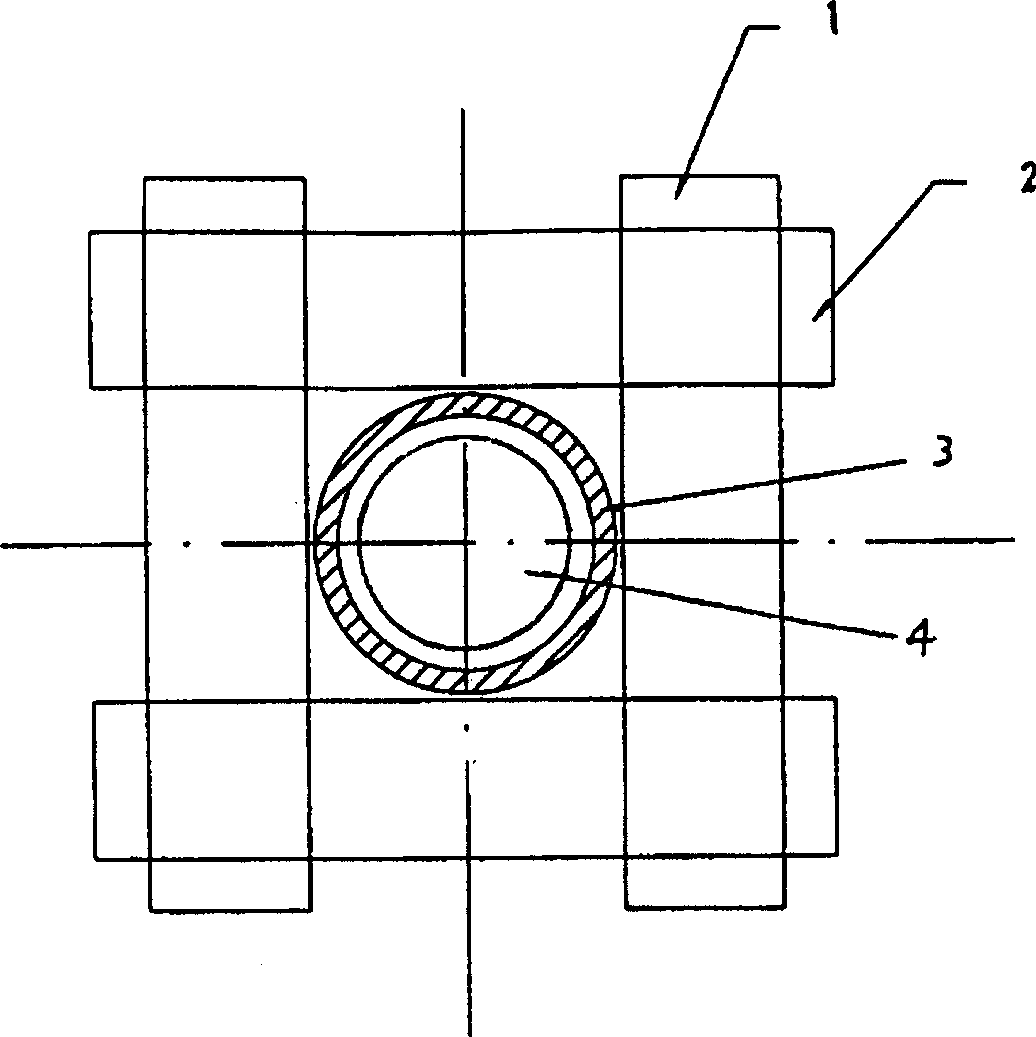

[0008] figure 1 It is a schematic diagram of the basic structure mode of the present invention.

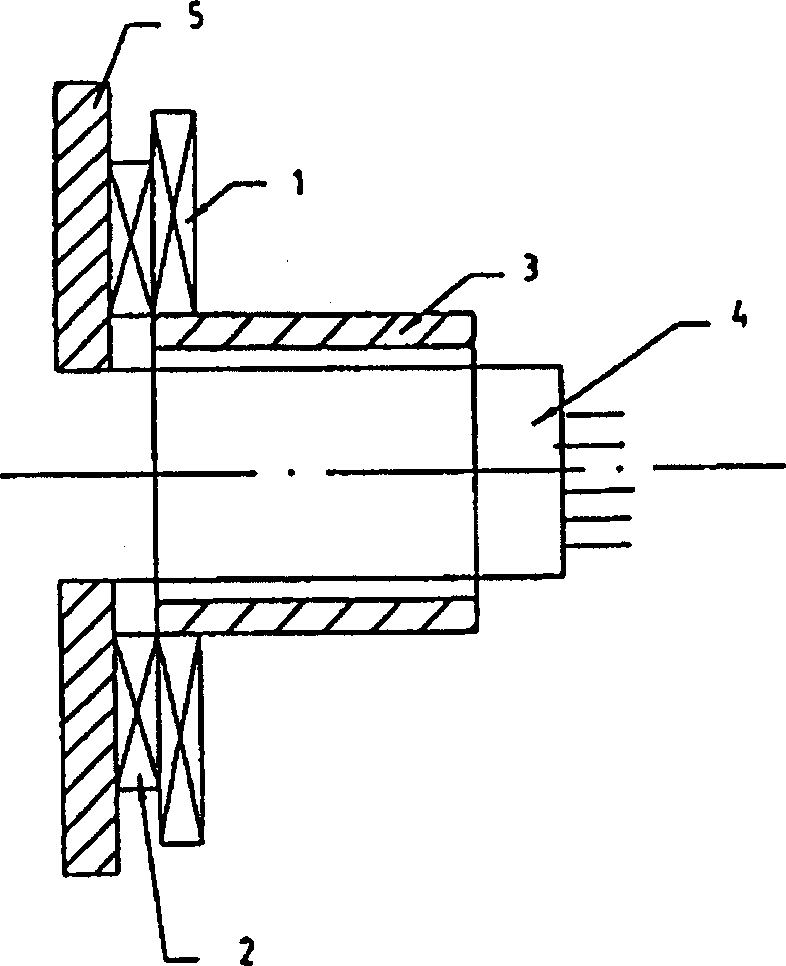

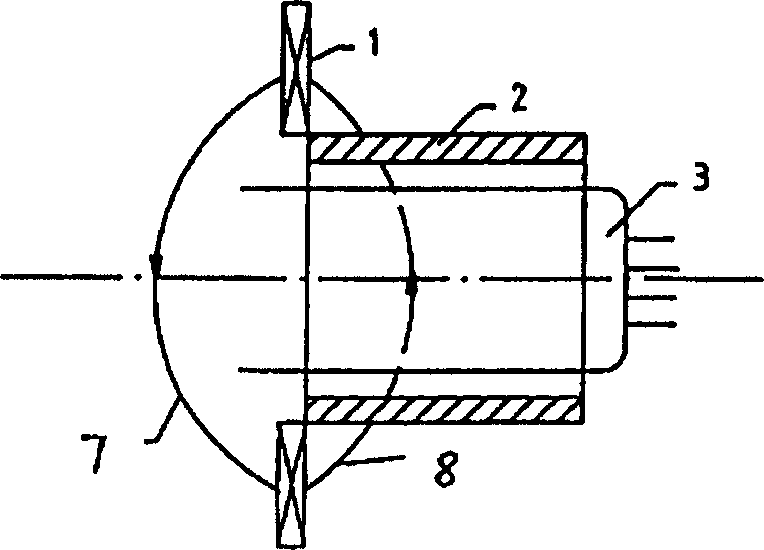

[0009] As shown in the figure, the basic structural model of the ultra-large deflection planar coil without a ferrite core includes a pair of planar rectangular frame deflection coils 1 and a pair of planar rectangular row deflection coils 2. The two pairs of deflection coils are placed perpendicular to each other on a plane. There is a magnetic shielding ring 3 perpendicular to the plane where the coils are located in the center of the two pairs of deflection coils.

[0010] The magnetic shielding ring 3 is made of high magnetic permeability material, which can be placed on the outside of the electron gun barrel neck 4, and the inner diameter of the central hole is determined by the outer diameter of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com