Continuous coating furnace

A coating and connection technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problem of affecting product quality, the inability to achieve accurate adjustable and controllable oxygen concentration, and poor performance of the coating furnace. Standards and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

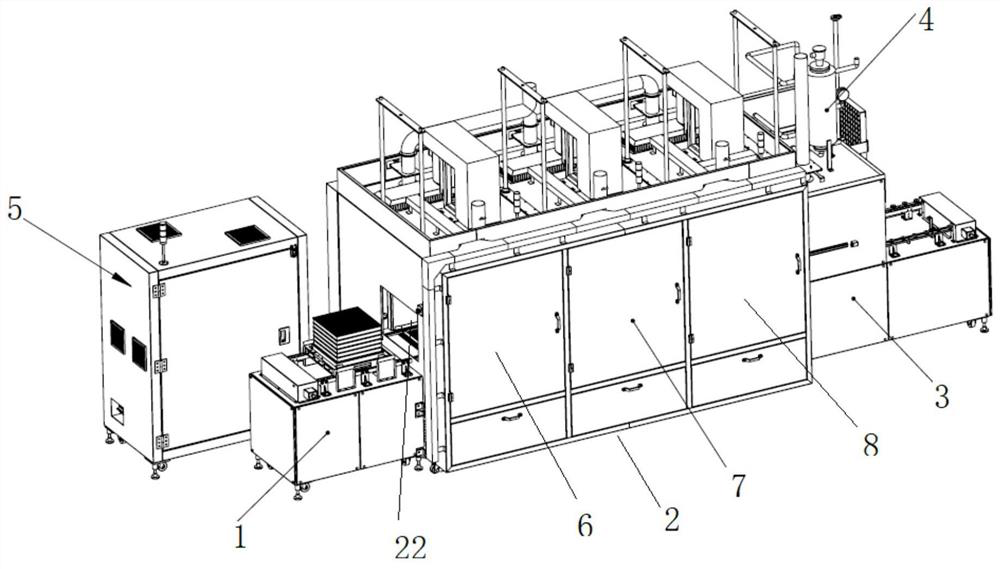

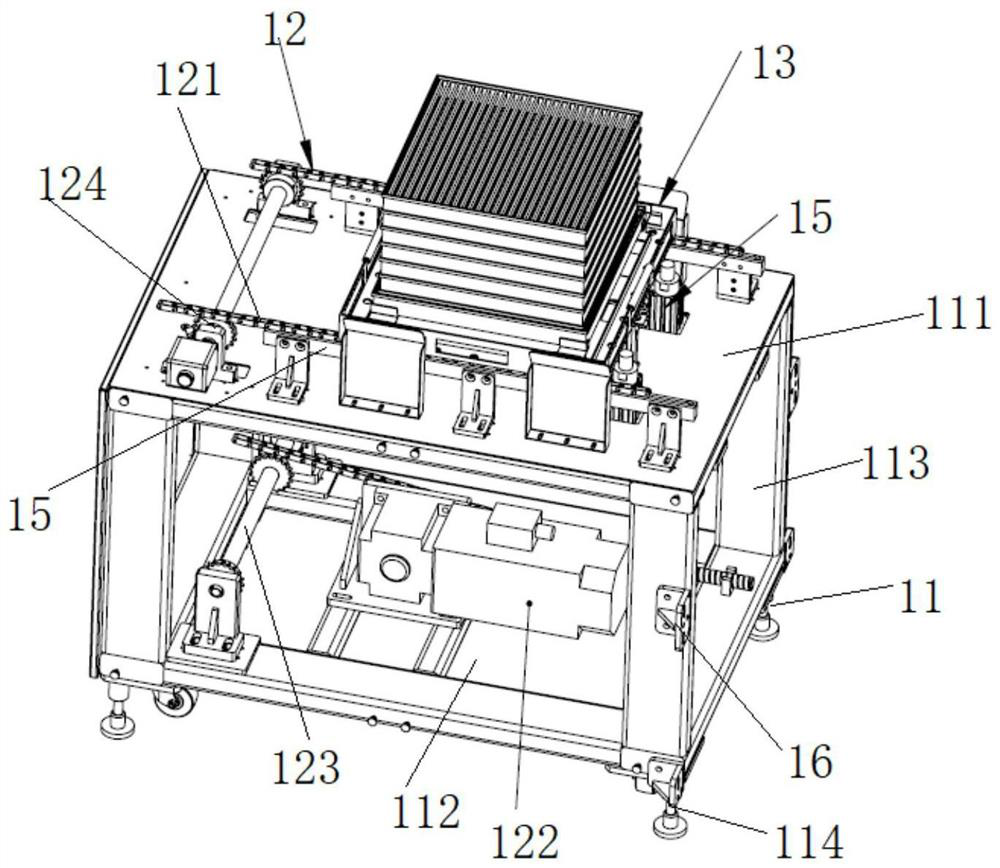

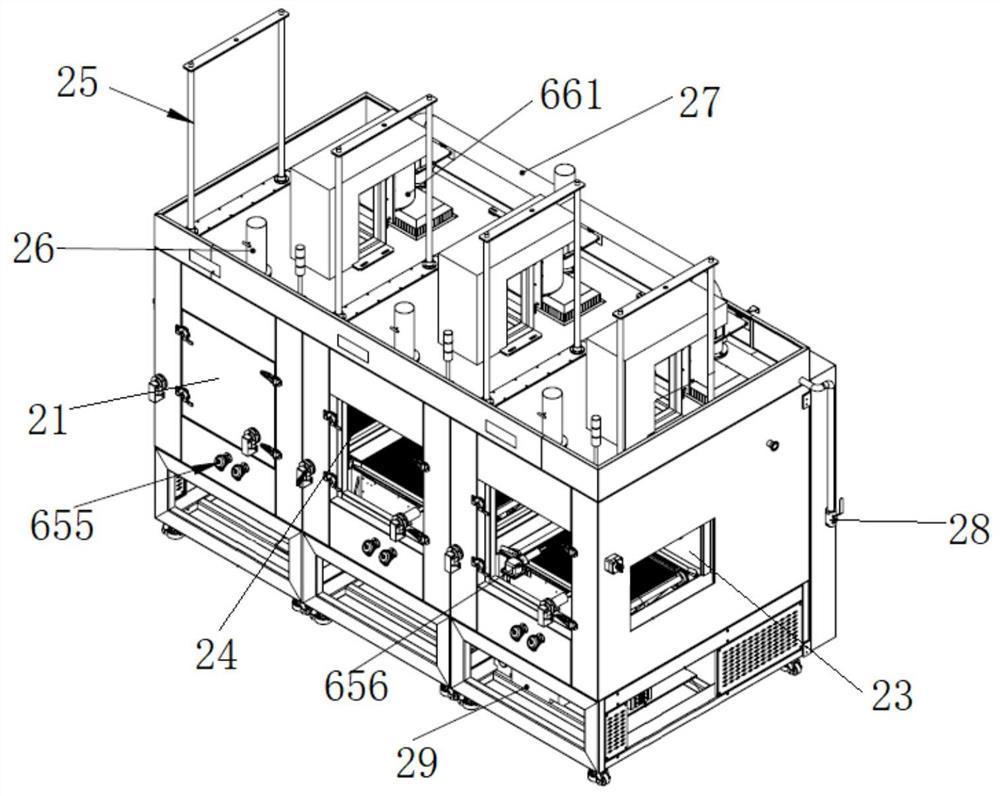

[0034] A continuous coating furnace disclosed by the present invention mainly realizes the thermal decomposition operation of the tantalum capacitor impregnated with the manganese nitrate solution, and includes automatic loading before the thermal decomposition operation and automatic unloading after the thermal decomposition. The specific structure is as follows figure 1 As shown, it includes feeding structure 1, thermal decomposition mechanism 2, cooling and unloading mechanism 3, water vapor heating mechanism 4 and electric control box 5. The feeding mechanism sends impregnated tantalum capacitors into the therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com