Combustor with low-vortex combustion feature

A technology of combustion characteristics and burners, which is applied to gas fuel burners, burners, combustion methods, etc., and can solve problems such as difficulty in adapting to the atmospheric environment, incomplete combustion of the burner, and inability to automatically adapt to thin air at high altitudes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

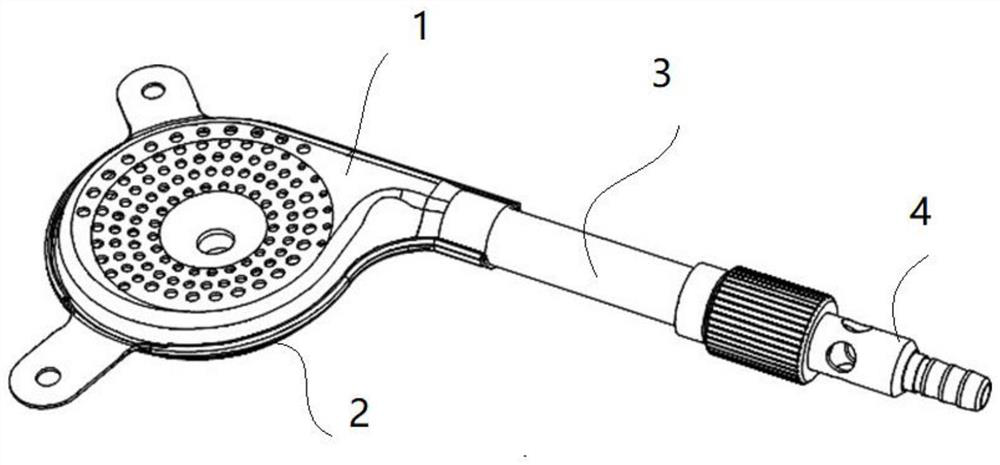

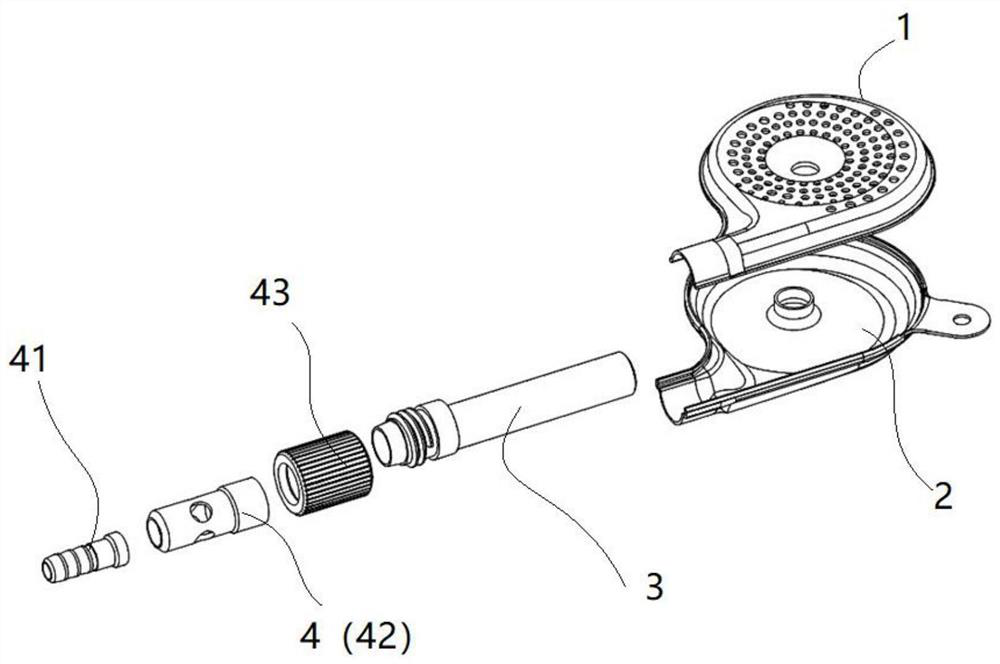

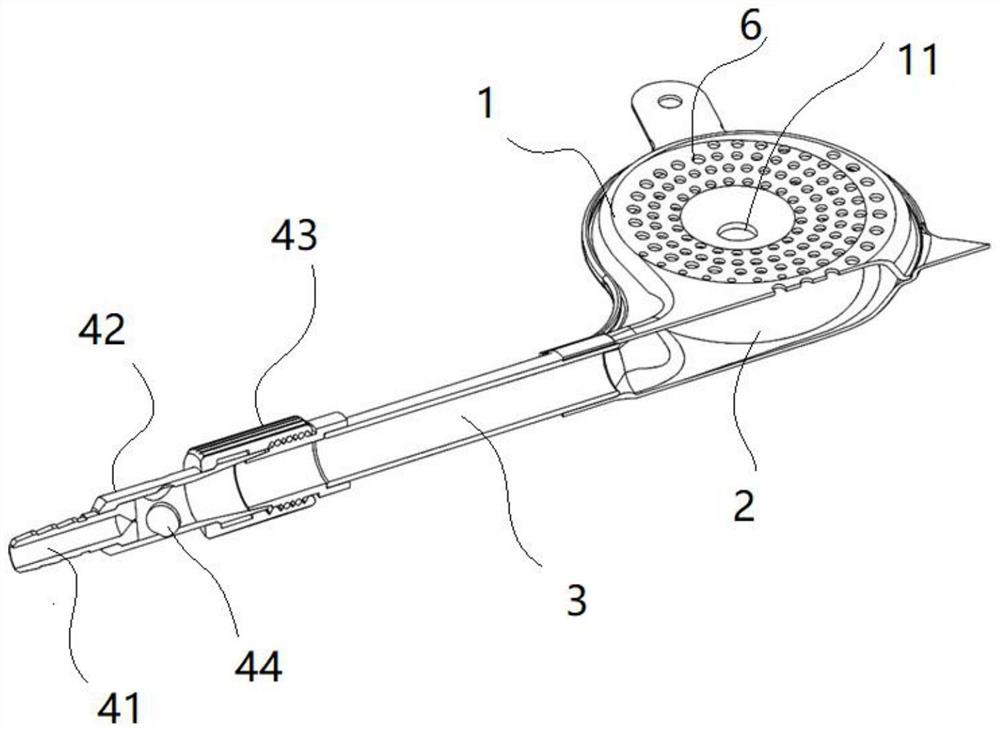

[0044] Such as Figure 1-7 Shown is a specific embodiment of the burner with low swirl combustion characteristics implemented according to the present invention. Other routine changes and designs according to those skilled in the art are all within the scope of the concept of the present invention.

[0045] The burner with low swirl combustion characteristics implemented according to the present invention at least includes: an upper cover 1, a lower cover 2, a Venturi mixing tube 3, and a nozzle throat assembly 4;

[0046] The upper cover 1 and the lower cover 2 are both round and half-volute spiral discs, and the air intake channel is smoothly combined with the volute from the horizontal tangent direction of the circular volute to form an integrated cover;

[0047] The upper cover 1 and the lower cover 2 are interlocked to form a whole with a volute-shaped combustion space, and the air intake passage communicates with the Venturi mixing tube 3; the outer end of the Venturi m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com