Closed circulating cooling method for cogeneration unit

A cogeneration unit and closed cycle technology, which is applied to irreversible cycle compressors, refrigerators, compressors, etc., can solve the problems such as the inability to meet the steam extraction and heating conditions of cogeneration units, and reduce power, High environmental protection effect, the effect of compensating for the fluctuation of cold source temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

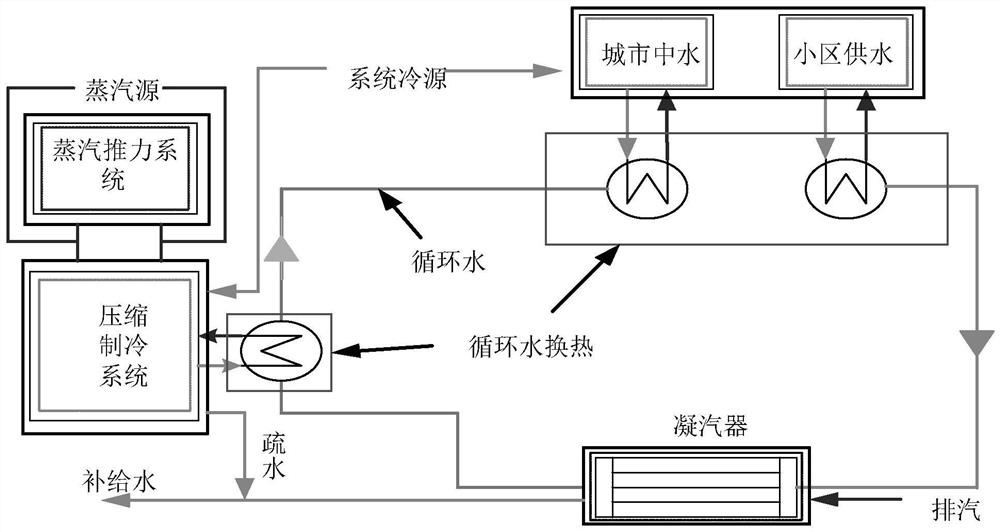

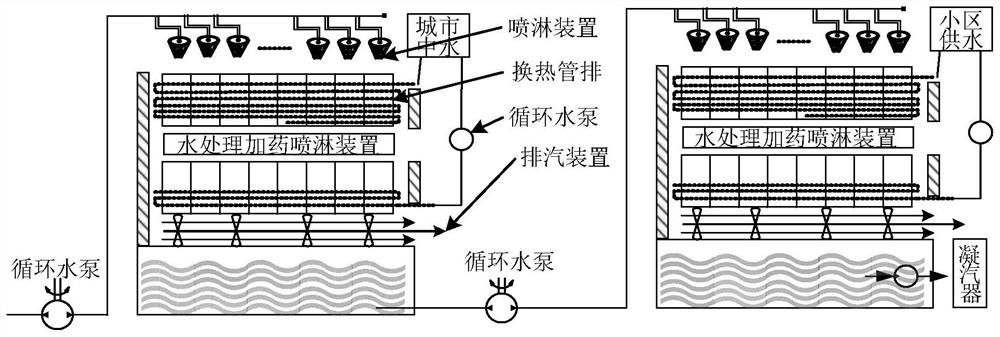

[0017] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment, a closed cycle cooling method for a cogeneration unit described in this embodiment, the closed cycle cooling method includes:

[0018] The steam thrust system is used to drive the compression refrigeration system, the cooling tower is removed, and urban reclaimed water and domestic water are introduced as cooling sources.

[0019] In the present invention, in order to realize the complete removal of the cooling water tower, the reclaimed water in the city and the domestic water in the community are used as cooling sources to cool the circulating water. As the driving force of the compression refrigeration system, the compression refrigeration system can compensate for the fluctuation of the temperature of the urban reclaimed water and the domestic water in the community due to the change of the ambient temperature. At the same time, a steam-propelled refrigerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com