Multi-camera networking positioning calibration method for aircraft digital assembly

A calibration method and unit technology, applied in the field of digital measurement, can solve the problems of poor practical application effect, high price of high-precision instruments and equipment, and high cost of measurement system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The multi-camera network positioning calibration method for aircraft digital assembly of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

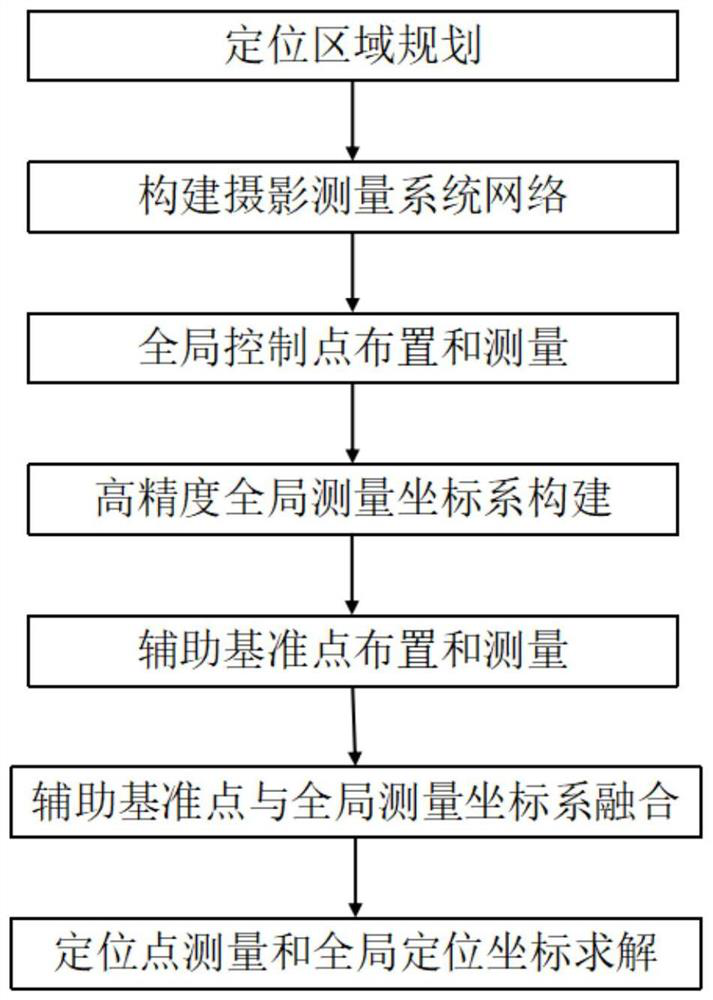

[0047] Such as figure 1 As shown, a multi-camera network positioning and calibration method for aircraft digital assembly includes the following steps:

[0048] Step 1. Determine the positioning object and plan the positioning area.

[0049] The positioning object refers to the reference point selected on the outer surface of the device to be positioned (such as a structured light scanner, tracker) as a point to be measured.

[0050] The positioning area planning process is as follows: determine the positioning range of the positioning object, and select the convex polyhedron area of the spatial position that the positioning equipment can reach when measuring the shape of the aircraft as the measurement area.

[0051] Step 2: Build a multi-came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com