Axle box generator and bogie

A generator and axle box technology, applied in bogies, electromechanical devices, electrical components, etc., can solve problems such as safety accidents, difficulty in adjusting and setting the gap between rotor and stator, damage to axle box generator components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It can be known from the background art that the axle box generator in the prior art cannot well maintain the safety gap between the stator and the rotor.

[0027] A specific description will be given below in conjunction with an axle box generator and a wheel set bearing.

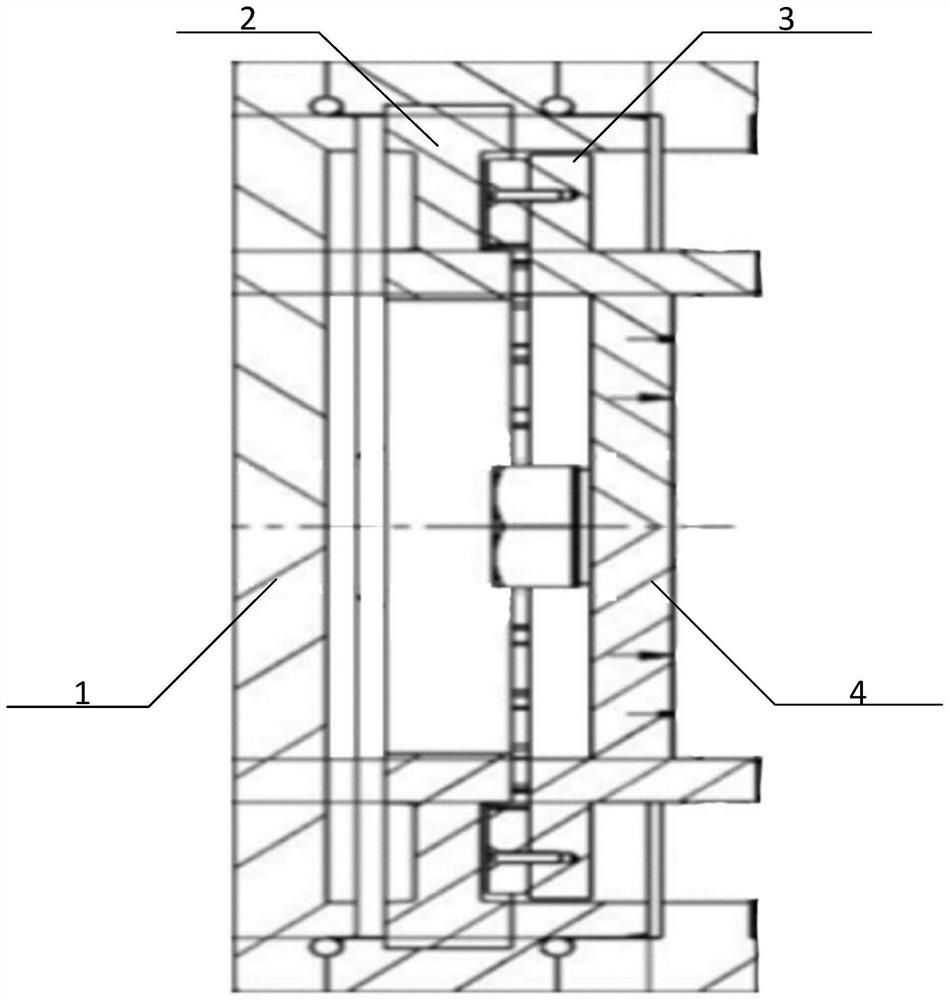

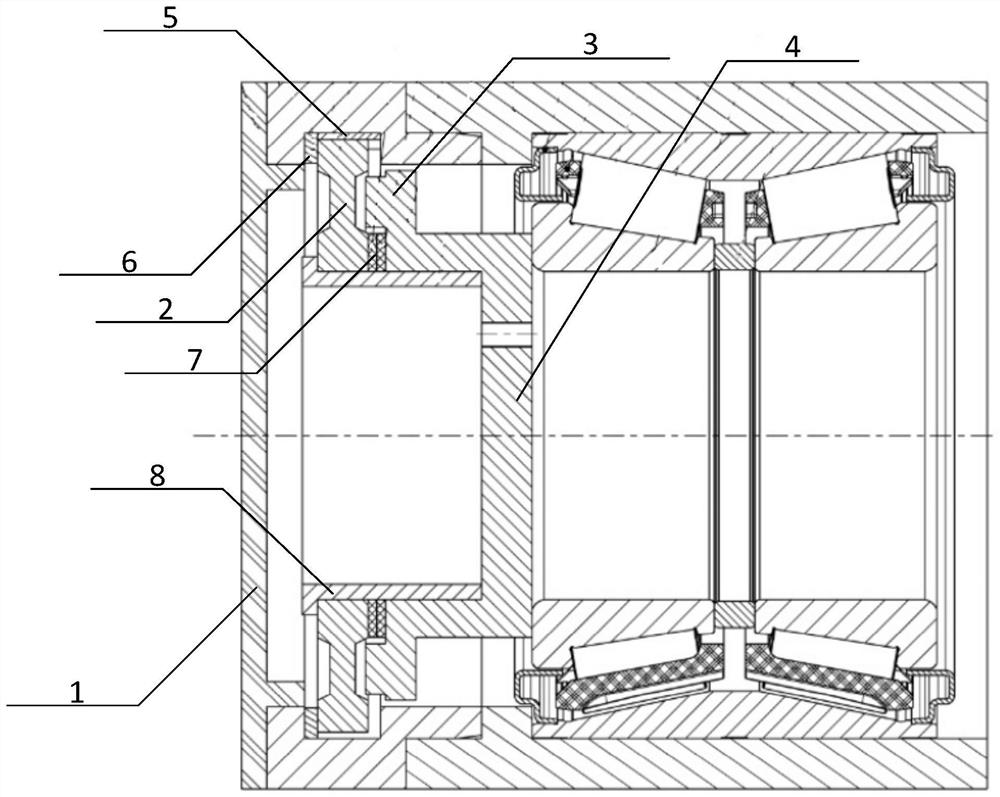

[0028] Please refer to figure 1 , figure 1 It is a longitudinal section schematic diagram of an axle box generator and a wheel set bearing.

[0029] Such as figure 1 As shown, the axle box generator includes:

[0030] first end cap 1;

[0031] A stator 2, the stator 2 is fixedly connected to the first end cover 1;

[0032] A rotor 3, the end face of the rotor 3 is opposite to the end face of the stator 2 with a gap between them;

[0033] The second end cover 4 , the rotor 3 is fixedly connected with the second end cover 4 .

[0034] One of the stator 2 and the rotor 3 is provided with a coil, and the other is provided with a magnet. The axle box generator is installed on at least any one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com