A kind of beneficiation method of accumulation type bauxite

A beneficiation method and bauxite technology are applied in the recovery of accumulation-type bauxite and in the field of beneficiation of accumulation-type bauxite, which can solve the problems of waste of resources, soil erosion, increase the cost of alumina smelting, etc., so as to reduce the sludge content. efficiency, energy-saving treatment, and the effect of realizing process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

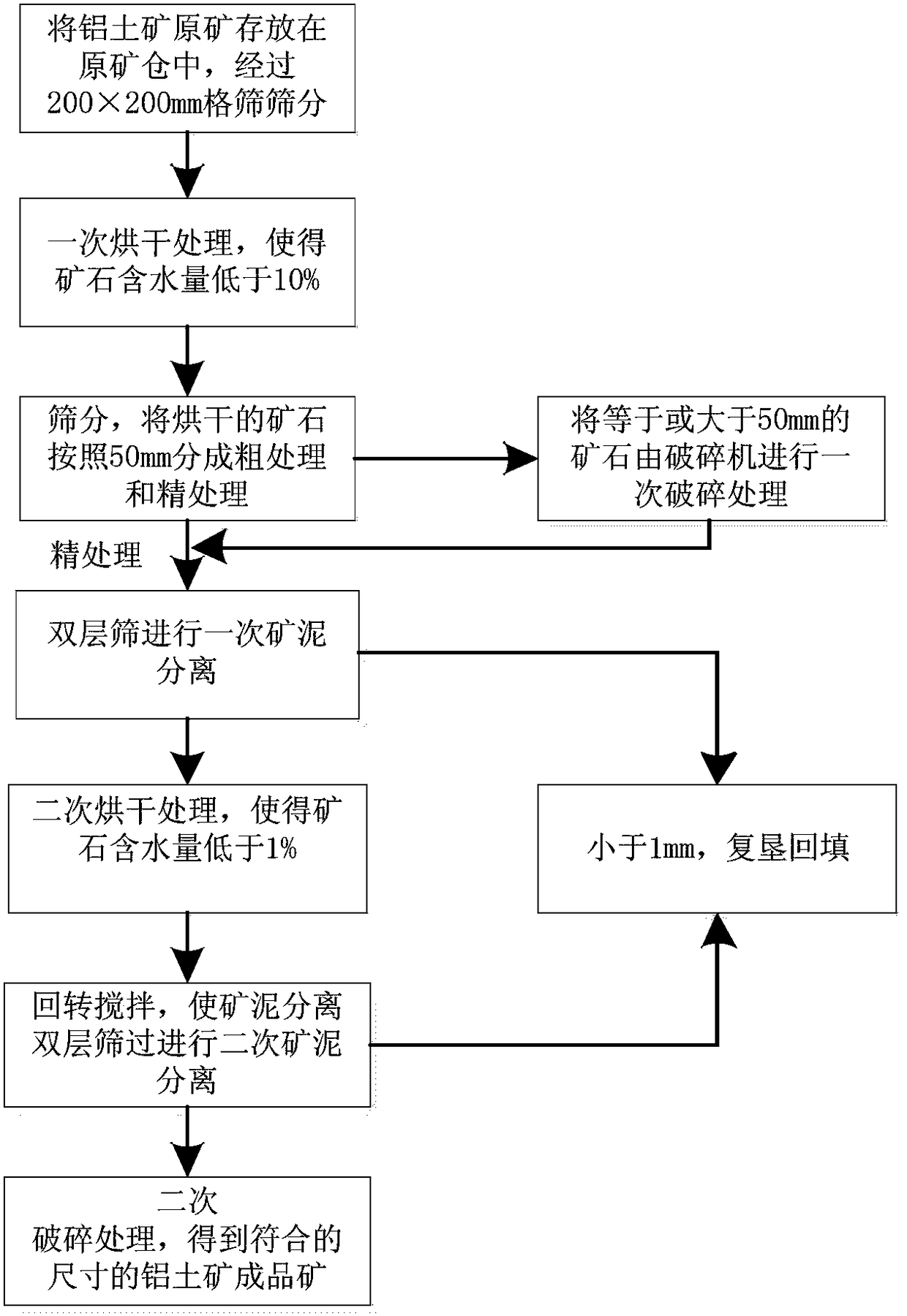

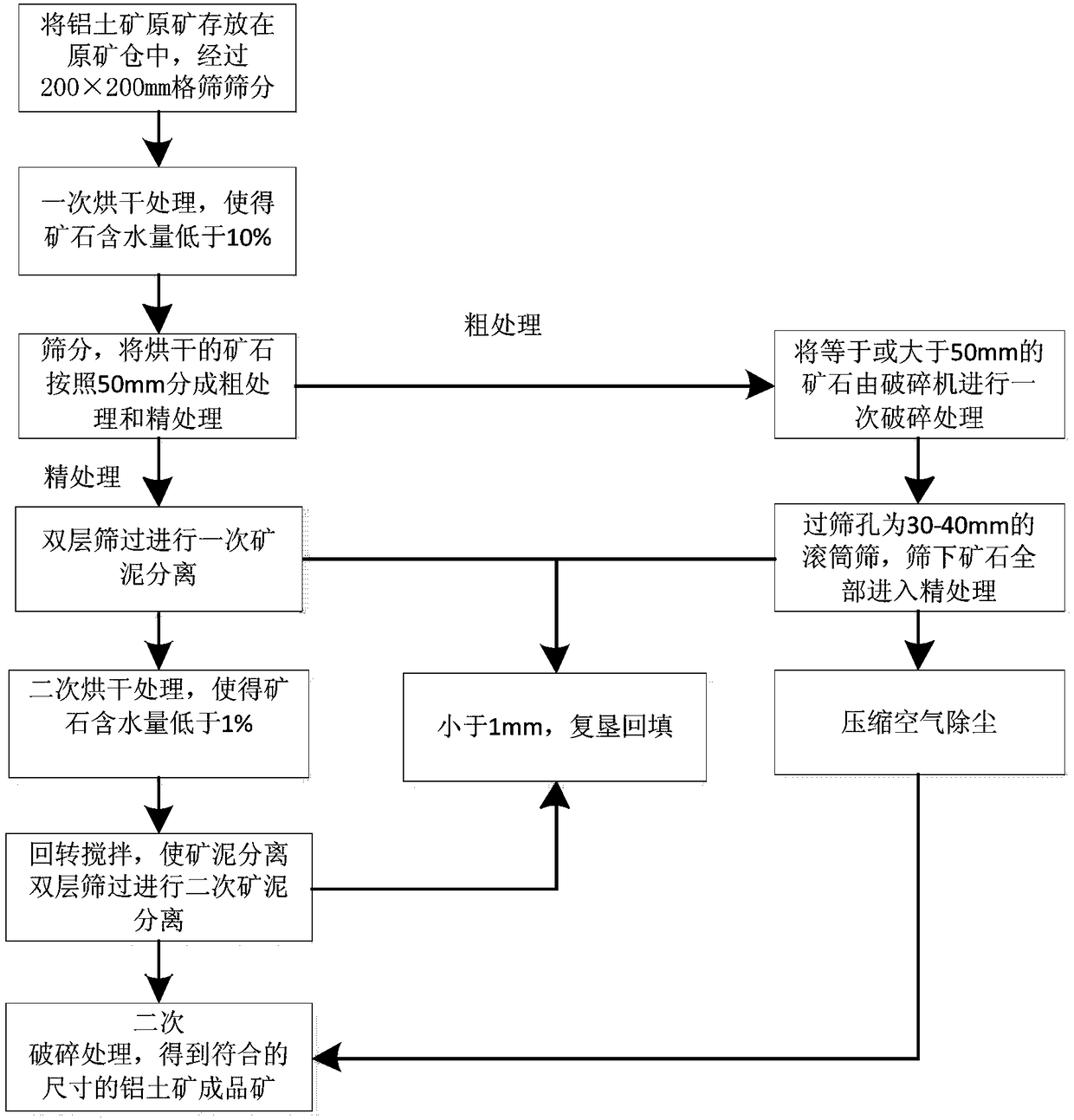

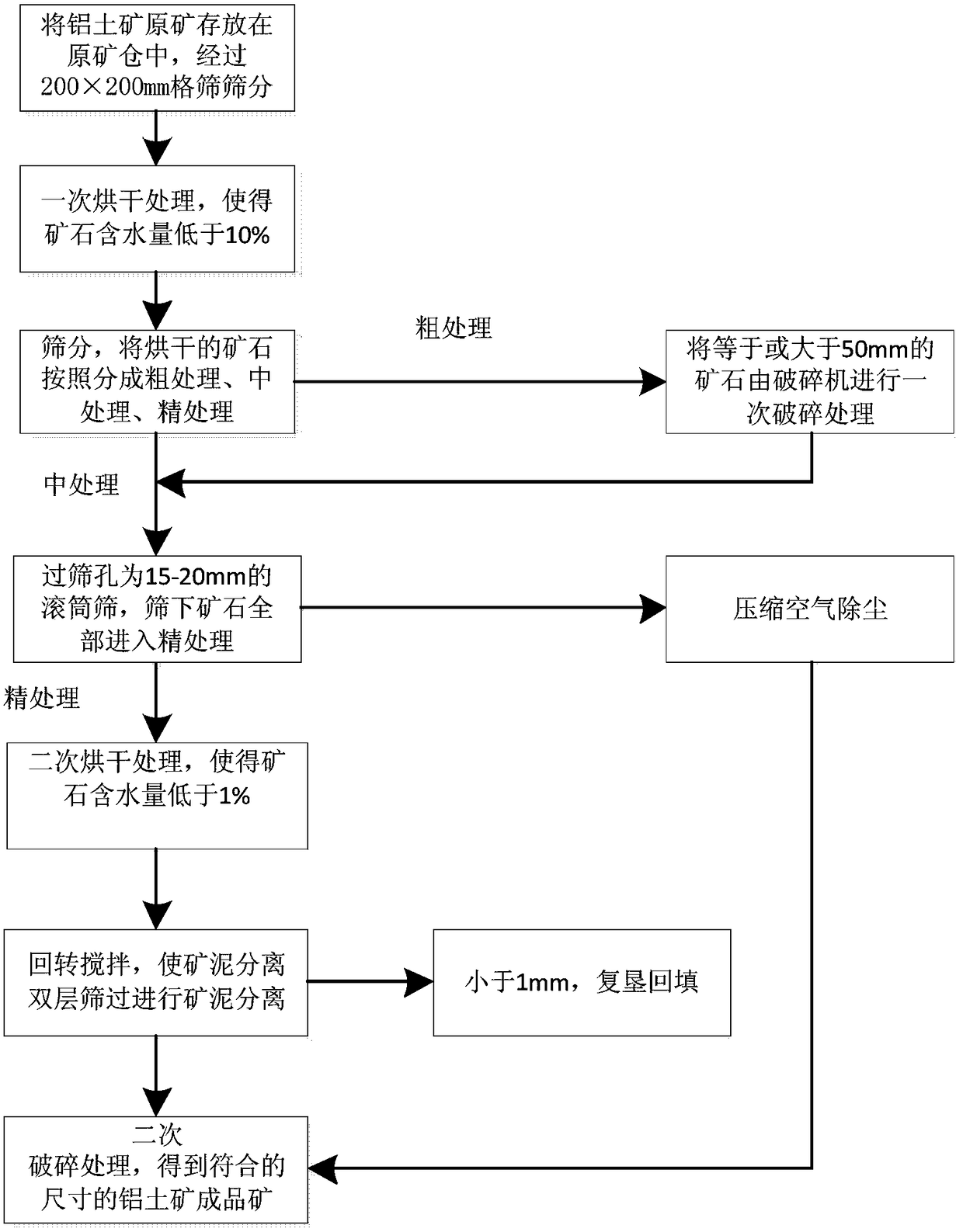

[0024] The invention discloses a beneficiation method of accumulation type bauxite. The bauxite raw ore is dried, screened and crushed to obtain the finished bauxite ore, and the bauxite raw ore is dried once to obtain the moisture content reduction method. to less than 10% ore; screen according to the size of the ore and carry out rough treatment and fine treatment; the rough treatment will crush the ore with a size greater than 50mm once to obtain ore less than 50mm, and send it to Refining treatment: In the refining treatment, the ore is separated from the ore through a double-layer separating screen, and then the ore is subjected to secondary drying treatment until the water content is lower than 1%, and the ore is rotated and stirred, and the secondary ore is carried out through the double-layer separating screen. After the mud is separated and dedusted by high-pressure air, it enters the secondary crushing process; the secondary crushing process crushes the ore to a speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com