Automatic chestnut stir-frying device for food processing

A technology of food processing and automatic turning, applied in food processing, application, food science and other directions, can solve the problems of endangering the personal safety of staff, low efficiency of stir frying, and physical exertion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

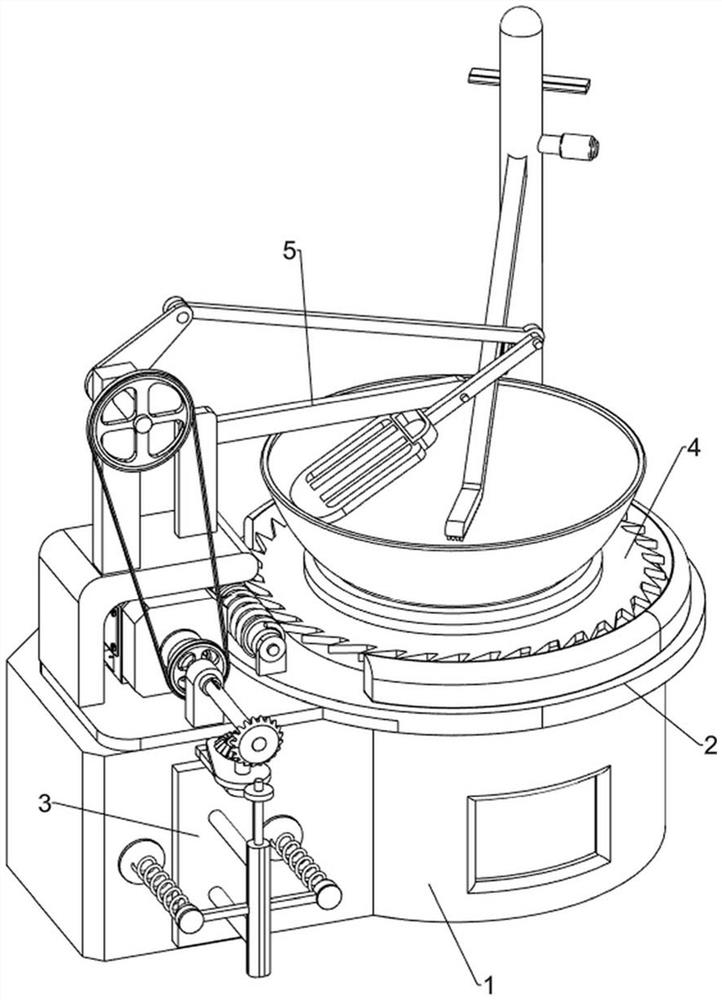

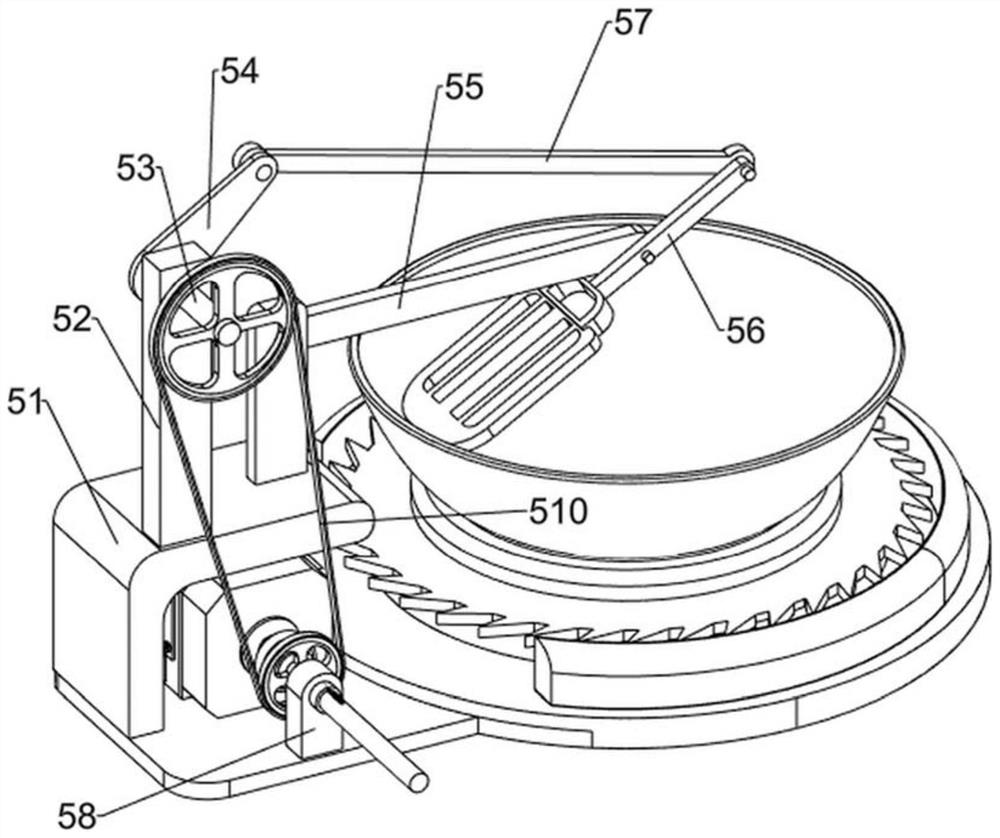

[0024] Such as Figure 1-4 As shown, a chestnut automatic stir-frying device for food processing includes a heating furnace 1, a mounting plate 2, a bellows 3, a rotating placement device 4 and a turning device 5, the top of the heating furnace 1 is provided with a mounting plate 2, and the inside of the heating furnace 1 A bellows 3 is provided on the left side, a rotating placement device 4 is provided on the top of the mounting plate 2 , and an overturning device 5 is provided on the left side of the top of the heating furnace 1 .

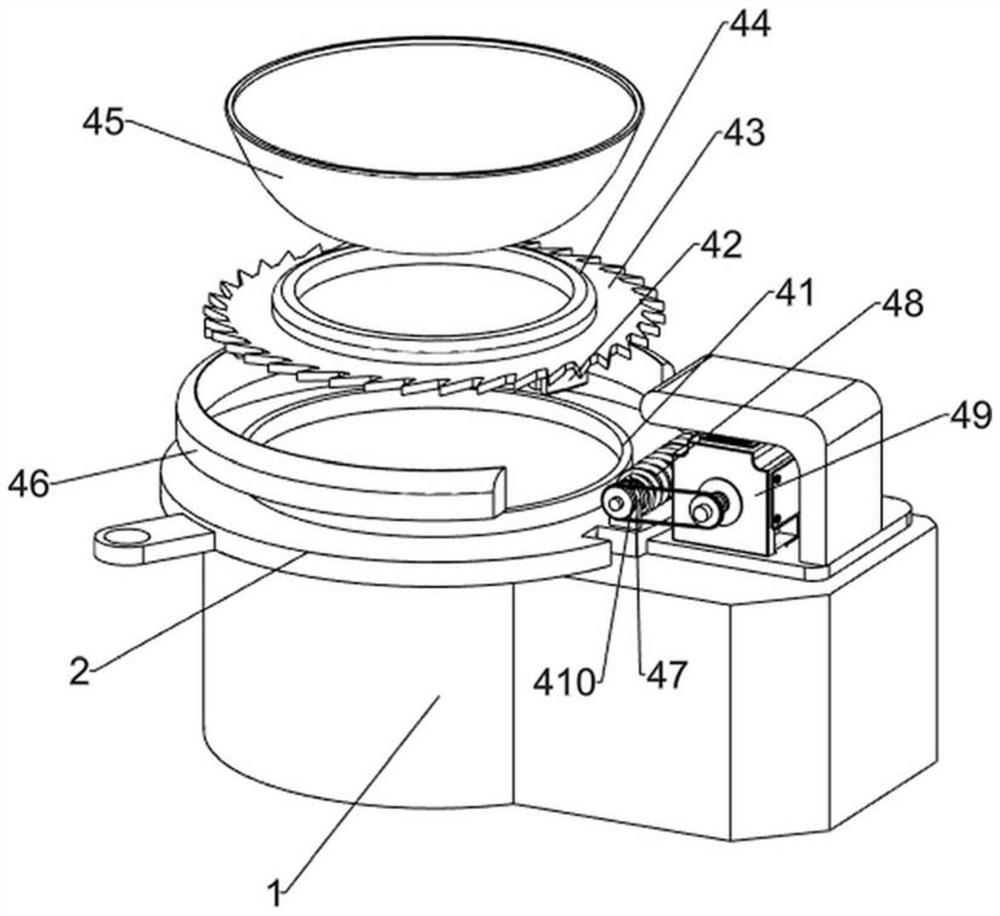

[0025] The rotary placement device 4 includes an annular slide rail 41, a slide block 42, a gear plate 43, a ring frame 44, a frying pan 45, an arc baffle plate 46, a first bearing seat 47, a screw rod 48, a biaxial motor 49 and a first belt The transmission mechanism 410, the top of the mounting plate 2 is provided with an annular slide rail 41, and a slider 42 is evenly slidably arranged on the annular slide rail 41, a gear plate 43 is arrange...

Embodiment 2

[0029] Such as Figure 5-6As shown, on the basis of Embodiment 1, it also includes a third bearing seat 6, a rotating shaft 7, a bevel gear 8, a cam 9, a push rod 10, a connecting rod 11 and an elastic member 12. The side of the heating furnace 1 close to the wind box 3 A third bearing seat 6 is arranged above the wall, a rotating shaft 7 is arranged on the third bearing seat 6, a bevel gear 8 is arranged on the front end of the moving rod 511 and the upper end of the rotating shaft 7, the two bevel gears 8 mesh, and a cam 9 is arranged in the middle of the rotating shaft 7 The top of the pull rod of the bellows 3 is provided with a push rod 10, the push rod 10 is squeezed and fitted with the cam 9, the middle part of the pull rod of the bellows 3 is symmetrically provided with a connecting rod 11, the two ends of the connecting rod 11 and the side wall of the heating furnace 1 close to the bellows 3 Elastic pieces 12 are arranged between them.

[0030] When the rotating slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com