Pipe simulation in-situ bioremediation device and method thereof

A technology of bioremediation and in-situ remediation, applied in the research field of bioremediation of groundwater in uranium mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

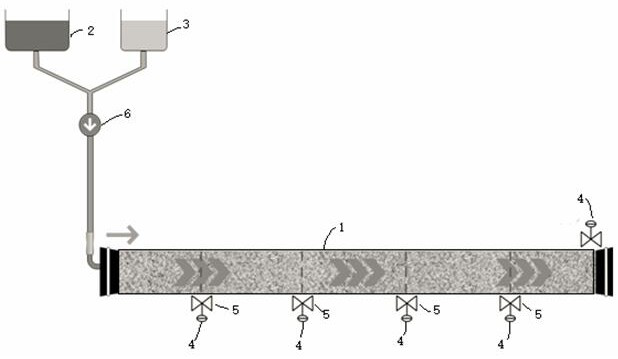

[0049] Such as figure 1 As shown, a pipe-simulating in-situ bioremediation device includes an in-situ bioremediation test tube 1, an ex-situ treatment effluent adjustment tank 2 connected to the in-situ bioremediation test tube 1, and a high-level carbon source supply tank 3. The interior of the restoration test tube 1 is uniformly filled with simulated ore-bearing aquifer ores, and both ends of the in-situ bioremediation test tube 1 are sealed and provided with a plurality of sampling monitoring ports 4 .

[0050] The ore in the simulated ore-bearing aquifer is an in-situ core sample, the number of sampling monitoring ports 4 is five, and each sampling monitoring port 4 is equipped with a valve 5. With flow meter6.

[0051] An in-situ bioremediation method of a tube simulating an in-situ bioremediation device, including S1. In-situ remediation simulation test and S2. Simulation research on seepage field and water chemical field during in-situ remediation.

[0052] Further, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com