Chemical strengthening method of glass, strengthened glass, application and display device

A technology for strengthening glass and display devices, which is applied in the fields of chemical strengthening of glass, strengthened glass, applications and display devices, and can solve problems such as difficult to protect electronic products, difficult to prepare comprehensive performance chemically tempered glass, damage to screens or cover plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

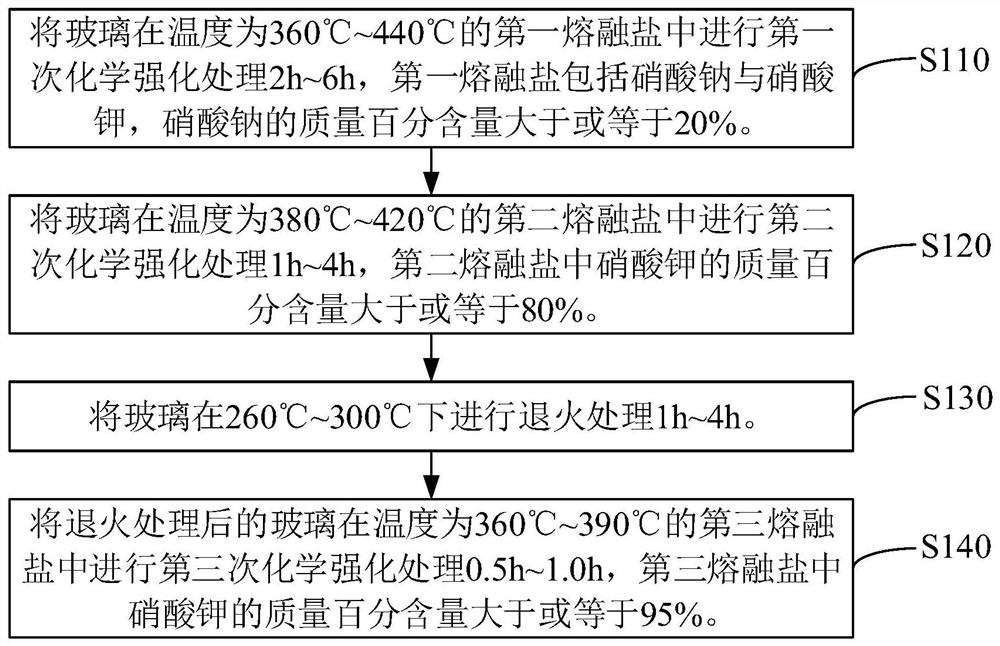

Method used

Image

Examples

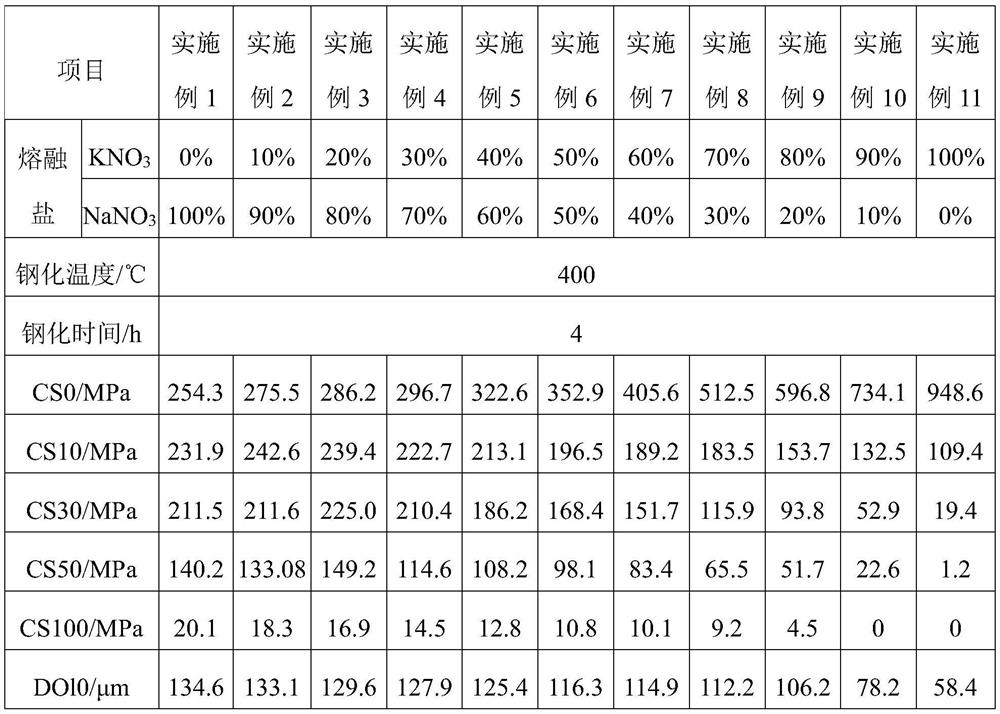

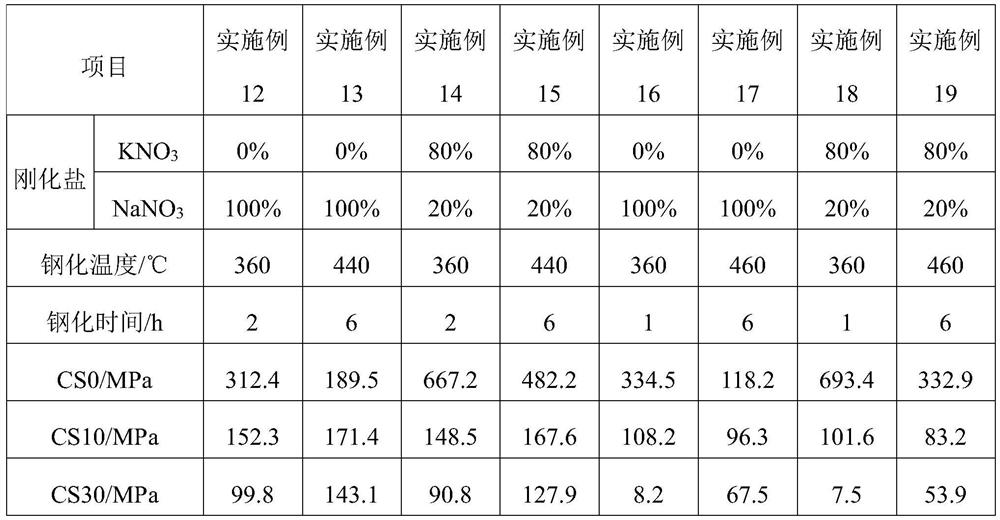

Embodiment 1~ Embodiment 11

[0076] The concrete process of the first chemical strengthening treatment of the glass of embodiment 1~embodiment 11 is as follows:

[0077] The first molten salt was prepared by mixing sodium nitrate and potassium nitrate according to the ratio (mass percentage) of sodium nitrate and potassium nitrate in Examples 1 to 11 shown in Table 1. Soak the above-mentioned polished glass sheets in the first molten salt of Examples 1 to 11 at 400° C. for 4 hours, so that the alkali metal ions in the glass and the alkali metal ions in the molten salt can undergo sufficient chemical ion exchange, By exchanging ions with large radii for ions with small radii, a jamming effect is generated to generate compressive stress and increase the strength of the glass. Wherein, embodiment 10 and embodiment 11 are comparative examples. After the first chemical treatment, the stress tester FSM6000UV and SLP1000 of Orihara Japan measured the surface compressive stress value CS0, the compressive stress ...

Embodiment 46~ Embodiment 50

[0108] The glass compositions of Examples 46 to 50 are specifically shown in Table 6. Wherein, embodiment 48 to embodiment 50 are comparative examples.

[0109] The preparation process of the glass of Example 46-Example 50 is the same as that of the glass of Example 1, and will not be repeated here.

[0110] The chemical strengthening process of the glass of embodiment 46~embodiment 50 is all the same, specifically as follows:

[0111] (1) The first chemical strengthening treatment: the same as the first chemical strengthening treatment process in Example 1, specifically: the glass is subjected to the first chemical strengthening treatment in the first molten salt at a temperature of 400 ° C for 4 hours, and the second A molten salt is sodium nitrate with a mass percent content of 100%.

[0112] (2) The second chemical strengthening treatment: the process is the same as that of the second chemical strengthening treatment in Example 22, specifically: the glass after the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com