Magnetron tube for carrying out magnetron sputtering

A magnetron and magnetic bar technology, which is applied in sputtering coating, ion implantation coating, metal material coating process, etc., can solve the problems of affecting the sputtering effect, internal cracking, uneven magnetic field on the target surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

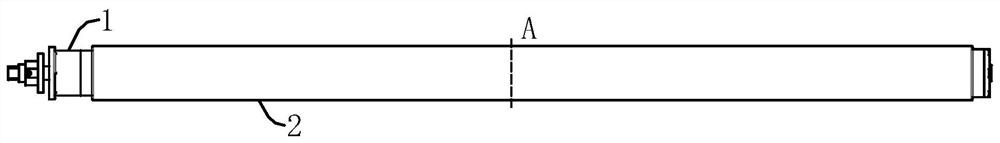

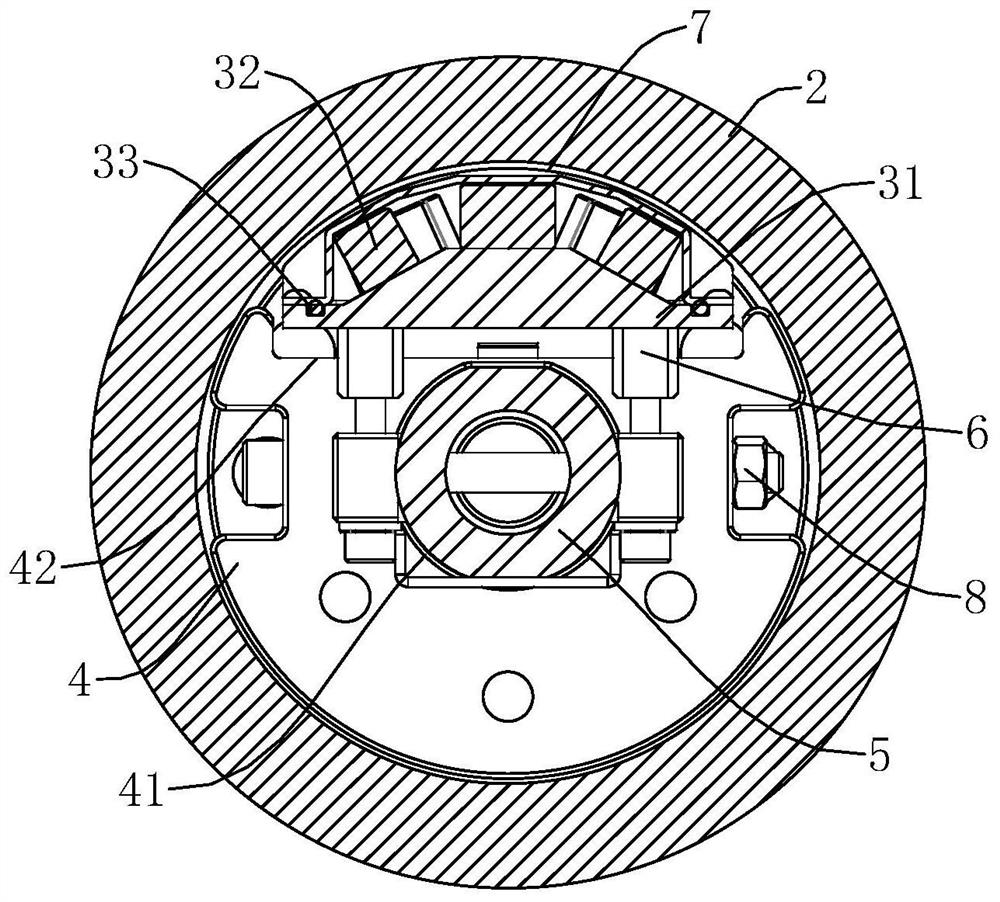

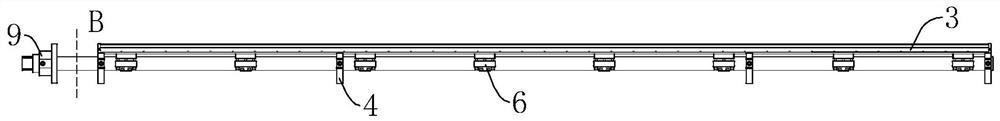

[0038] Such as Figure 1-4 As shown, the present application provides a magnetron 1 for implementing magnetron sputtering, which includes a cylindrical target material 2. The inside of the target material 2 serves as an installation chamber and is provided with a cathode magnet 3, and the installation chamber is along the target material. 2 A plurality of support frames 4 are arranged at intervals in the axial direction, and cooling water pipes 5 extending in the axial direction of the target 2 are fixed on the plurality of support frames 4;

[0039] The cathode magnet bar 3 includes a pole shoe 31 extending in the axial direction of the target 2 and a plurality of magnetic blocks 32 fixed on the top surface of the pole shoe 31. The top surface is also buckled with a sealing cover 7 for shielding the magnetic blocks 32.

[0040] In this embodiment, the magnetron sputtering coating needs to work at a very high power, so that the entire magnetron 1 will be in a higher temperature sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com