Magnet control system for magnetron sputtering device

A magnetron sputtering and control system technology, applied in sputtering coating, discharge tube, vacuum evaporation coating, etc., can solve the problem of excessive operating time, increased manufacturing costs, and the adjustment of magnetic field strength cannot be locally formed, etc. problem, achieve the effect of improving in-plane distribution and preventing local excessive erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

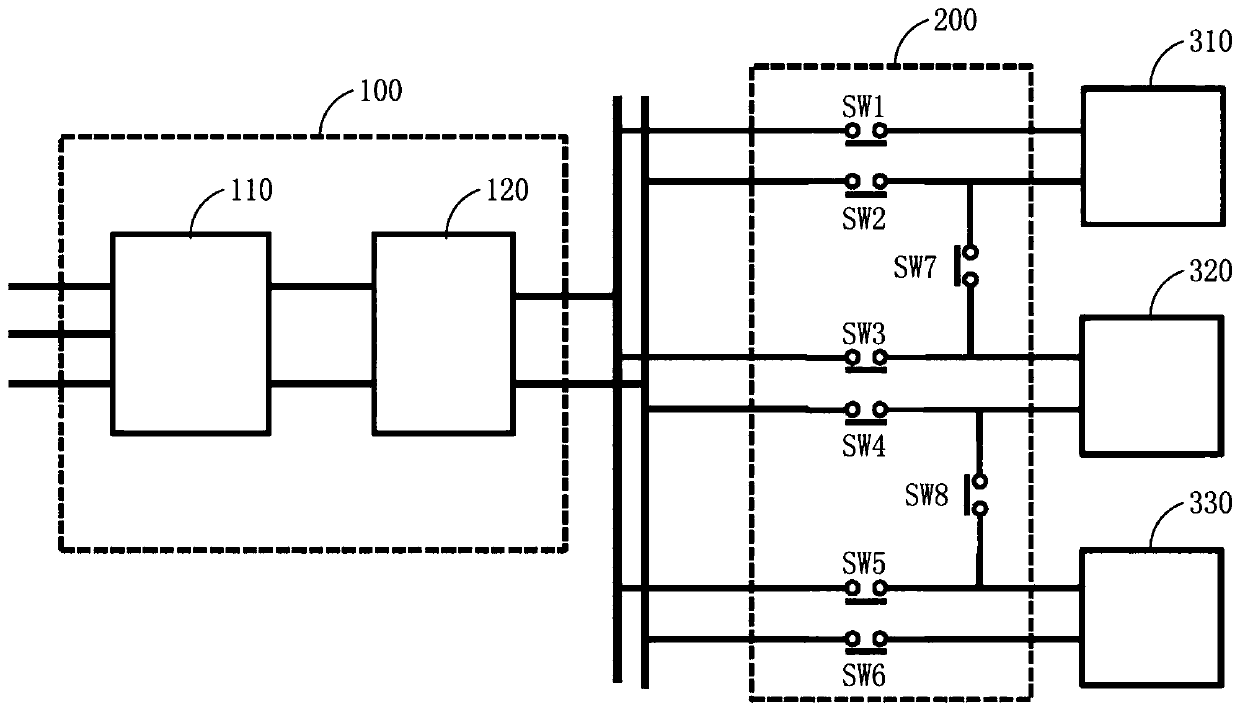

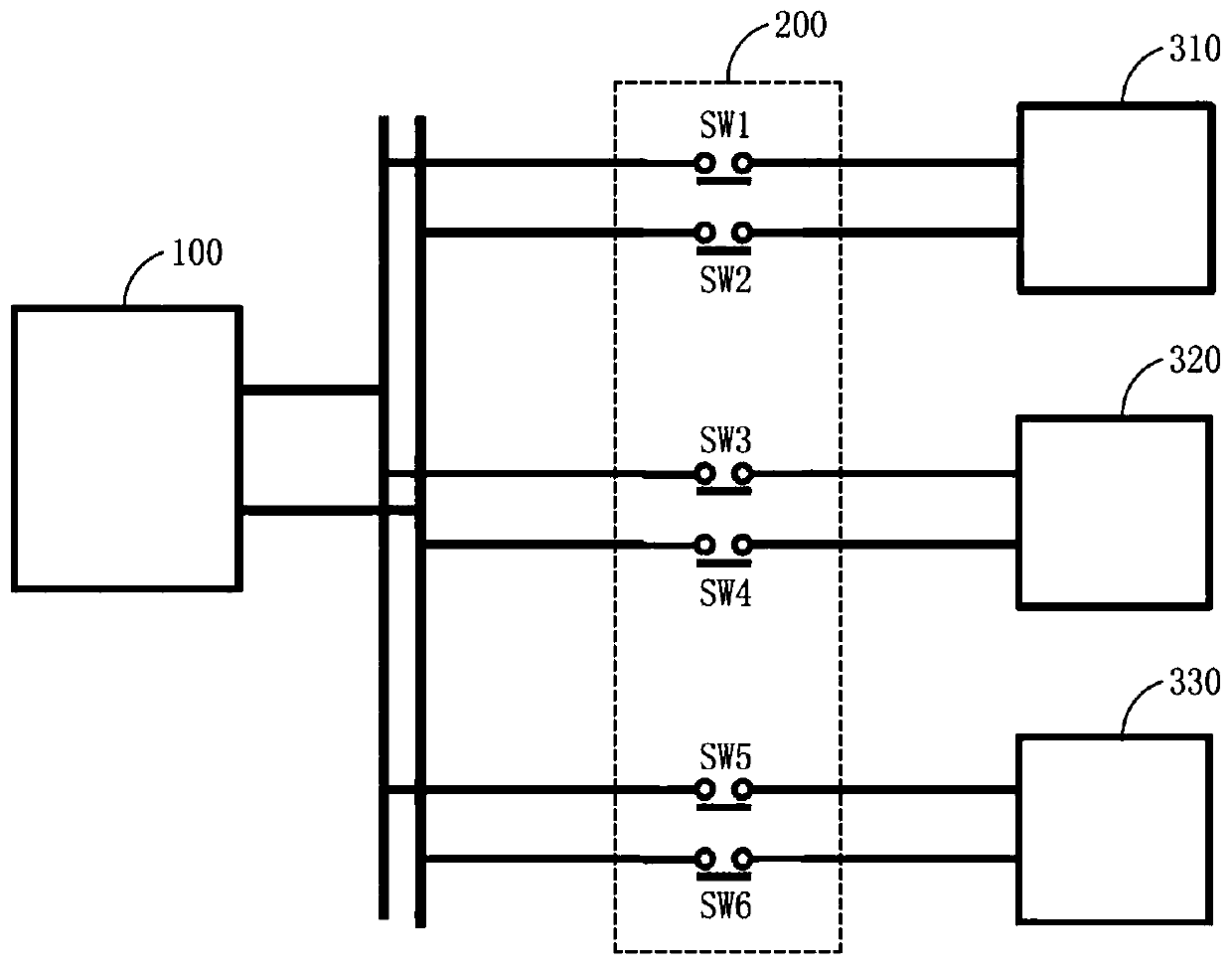

[0130] Figure 7a to Figure 7d It is shown that as an embodiment of the present invention, a magnet unit including a plurality of magnet structures such as Figure 5b A schematic diagram of the structure of the magnet structure connected after a part or the entire magnet assembly is connected to the drive power supply unit using a switch.

[0131] As an example of the present invention, a plurality of magnet structures including T-shaped permanent magnets and coiled permanent magnet wires were produced. connection arrangement of the magnet structures, forming as Figure 5b magnet unit. A switch is used to selectively apply current to a part or all of the magnet combination, and the magnetic field strength at the center of the first magnet group and the second magnet group is measured.

[0132] Figure 7a is a picture showing the configuration of the magnet unit for measuring the magnetic field strength constituted and for measuring the magnetic field strength, and Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com