Modular floor heating system and construction method thereof

A modular floor heating technology, applied in heating methods, hot water central heating systems, lighting and heating equipment, etc., can solve the problems of incompatibility between flexibility and practicability, poor wet floor heating technology, and low threshold, so as to achieve flexibility The effect of taking into account practicality, occupying less floor height, and reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

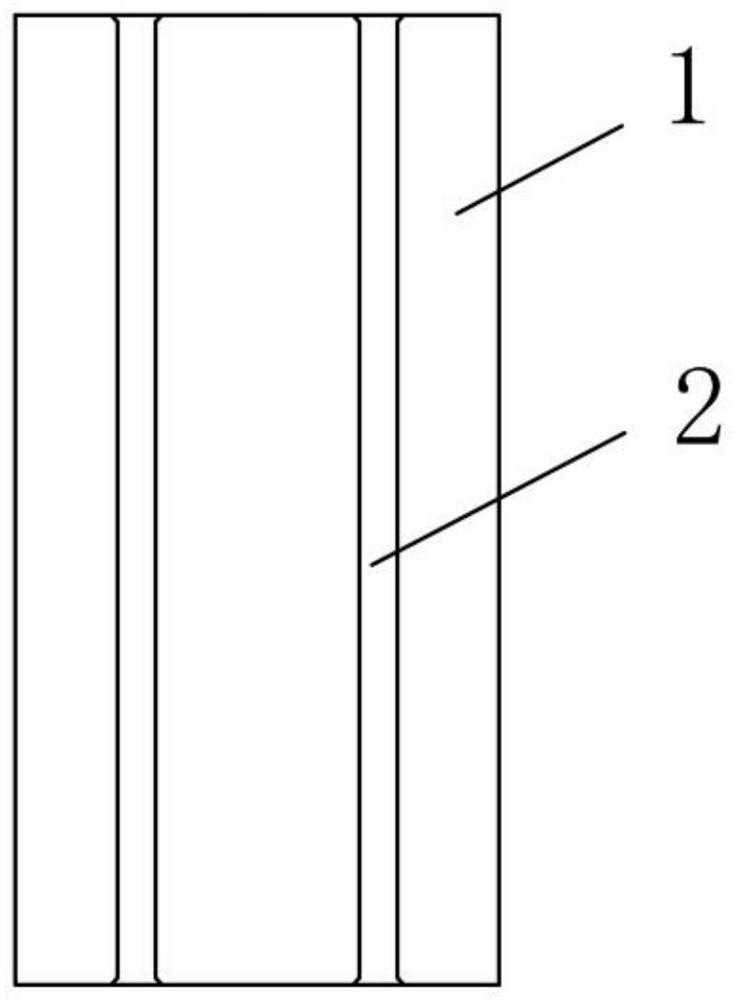

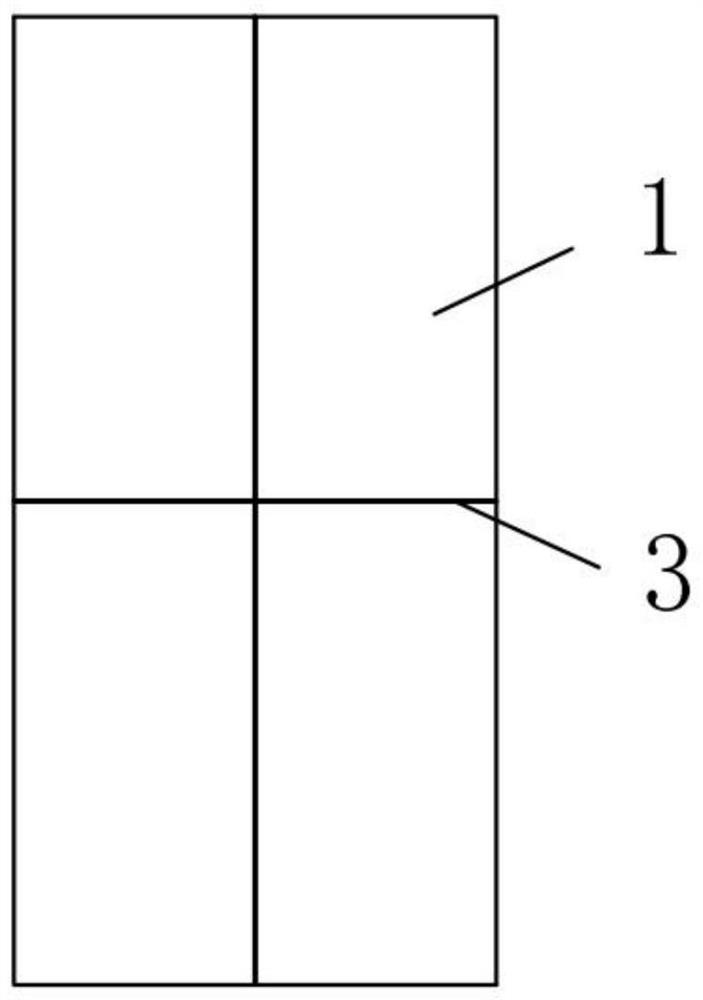

[0036] like Figure 1 to Figure 6 and Figure 13 to Figure 14 As shown, a modular floor heating includes a base plate 1. A prefabricated panel groove 2 is opened in the top of the base plate 1. The prefabricated panel groove 2 is a linear groove. The connection ports of the prefabricated panel groove 2 have been passivated. There is a prefabricated slot 3 at the bottom of the bottom, through which the bottom plate 1 can be divided into several small modules, thereby facilitating the splicing of multiple groups of bottom plates 1 .

[0037] A construction method for modular floor heating, the specific method is as follows:

[0038] In the first step, the polystyrene foam material or the polyurethane foam material is press-molded with an extrusion die according to the product design drawing, so as to obtain the bottom plate 1;

[0039] The second step is to determine the type and quantity of floor 1 required after designing according to the customer's room type, and prepare re...

Embodiment 2

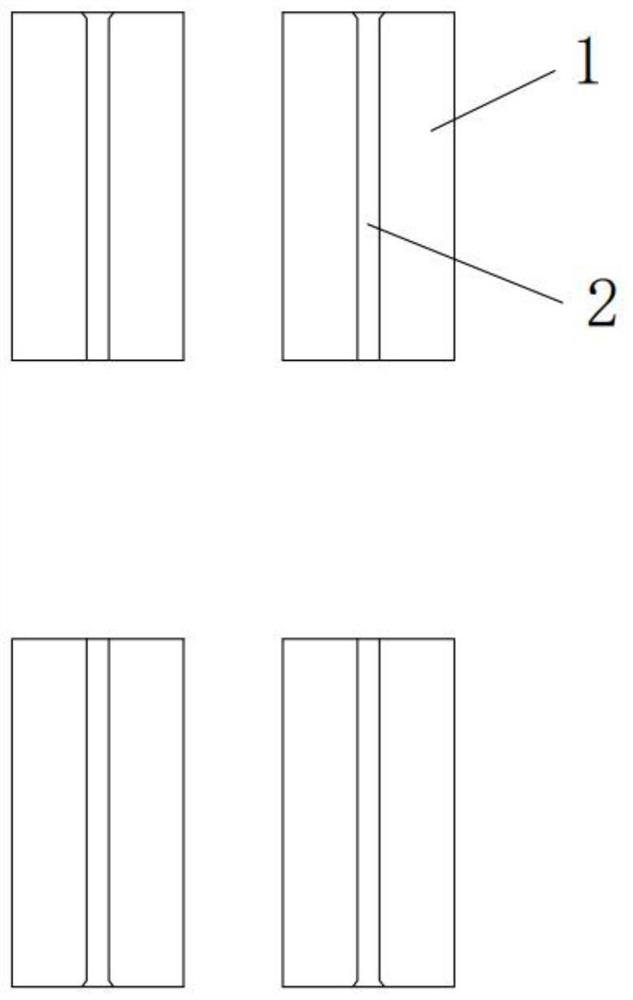

[0043] like Figure 7 to Figure 9 and Figure 13 to Figure 14 As shown, a modular floor heating includes a base plate 1, a prefabricated panel groove 2 is opened in the top of the base plate 1, the prefabricated panel groove 2 is a curved line groove, and the connection ports of the prefabricated panel groove 2 have been passivated. The bottom of the 1 is provided with a prefabricated cutting groove 3, and the bottom plate 1 can be divided into several small modules through the prefabricated cutting groove 3, thereby facilitating the splicing of multiple groups of bottom plates 1.

[0044] A construction method for modular floor heating, the specific method is as follows:

[0045] In the first step, the polystyrene foam material or the polyurethane foam material is press-molded with an extrusion die according to the product design drawing, so as to obtain the bottom plate 1;

[0046] The second step is to determine the type and quantity of floor 1 required after designing ac...

Embodiment 3

[0050] like Figure 10 to Figure 14 As shown, a modular floor heating includes a bottom plate 1, and a prefabricated plate groove 2 is opened in the top of the bottom plate 1. The prefabricated plate groove 2 is a straight line groove and a curved line groove. The wire slots are interconnected, and the connection ports of the prefabricated plate slots 2 have been passivated. The bottom of the bottom plate 1 is provided with a prefabricated slot 3, and the bottom plate 1 can be divided into several small modules through the prefabricated slot 3, so as to facilitate multiple groups of bottom plates. 1 splicing.

[0051] A construction method for modular floor heating, the specific method is as follows:

[0052] In the first step, the polystyrene foam material or the polyurethane foam material is press-molded with an extrusion die according to the product design drawing, so as to obtain the bottom plate 1;

[0053] The second step is to determine the type and quantity of floor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com