A construction method of circuitous guide pit for prevention and control of tunnel water inrush

A construction method and technology of inrush water, applied in tunnels, tunnel lining, drainage and other directions, can solve the problems of increasing investment cost, surrounding rock disturbance, prolonging construction period, etc., and achieve the effect of improving construction quality, improving structural strength, and avoiding construction interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

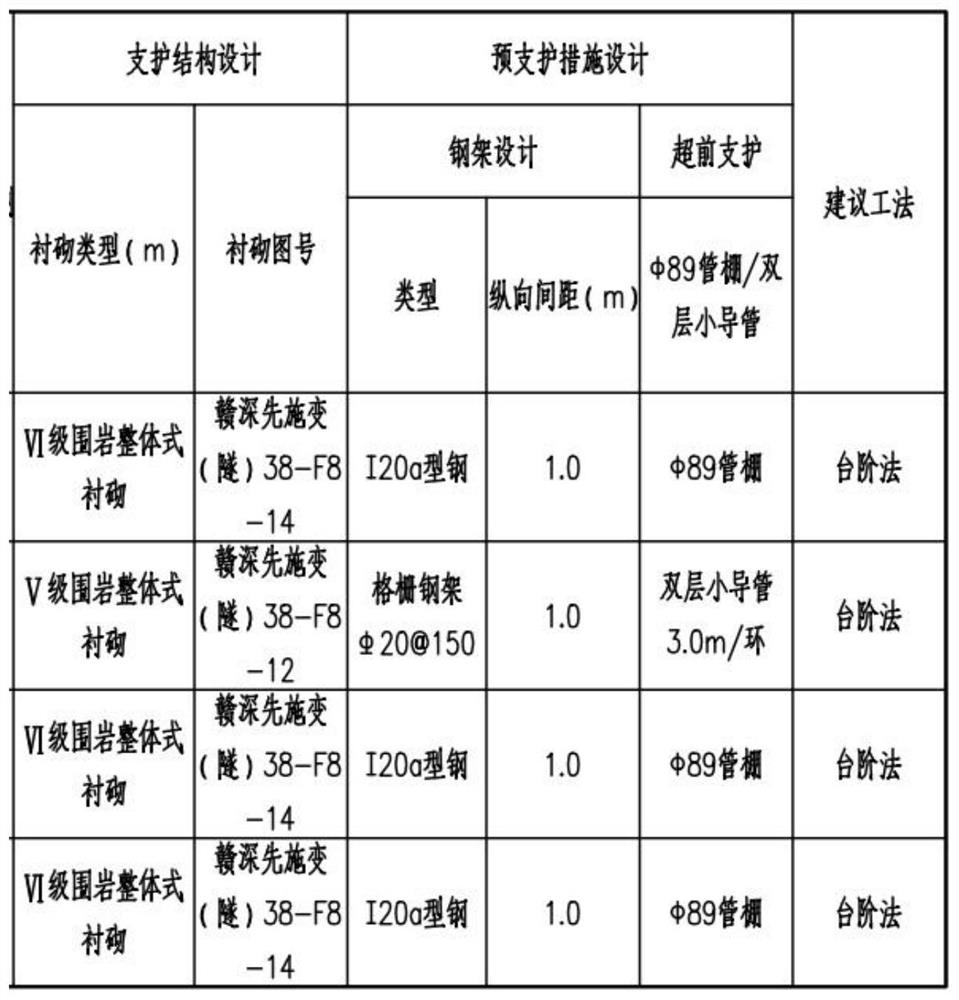

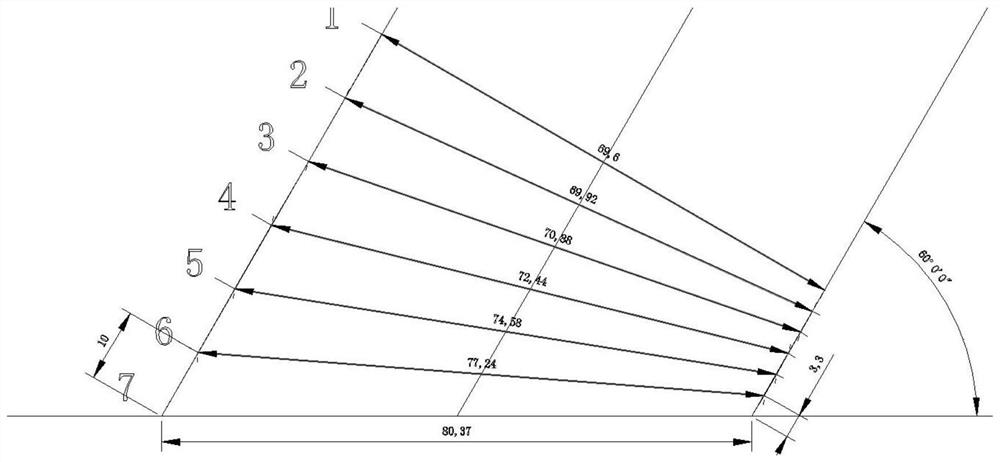

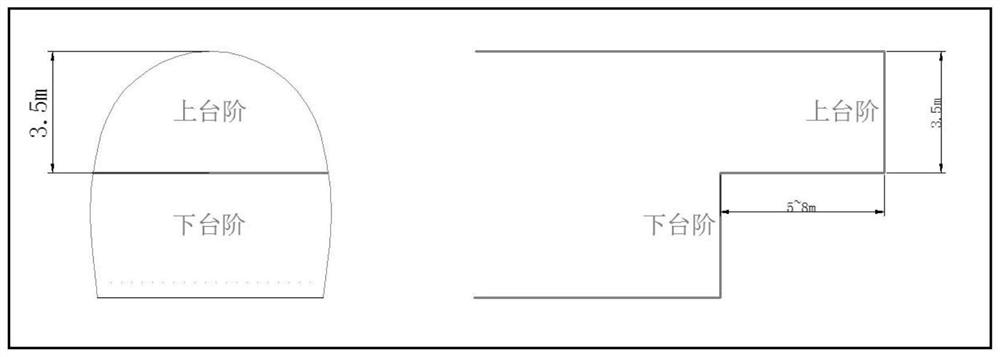

[0041] see Figure 1-4 , this embodiment provides a construction method for preventing tunnel water inrush and roundabout guide pit. The roundabout guide pit adopts a trackless transport single lane V-level composite section, the reserved amount of deformation is 15cm, and I-shaped steel is used to strengthen the support. It is characterized in that: Also includes the following steps:

[0042] S1: Pre-construction treatment;

[0043] S2: excavation by step method;

[0044] S3: support construction;

[0045] S4: advance support;

[0046] S5: shotcrete;

[0047] S6: Construction of weep holes on the side wall of the roundabout pilot pit.

[0048] In the construction method of the circuitous diversion pit for preventing tunnel water inrush provided by this embodiment, in the step S1, the pre-construction treatment includes:

[0049] Strengthen the support of the main hole arch frame at the junction of the main hole and the roundabout pilot pit top, and add locking feet. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com