High-frequency hydraulic vibration exciter

A hydraulic vibration exciter and high-frequency technology, which is applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of high energy consumption of hydraulic vibration excitation equipment, high energy consumption systems, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

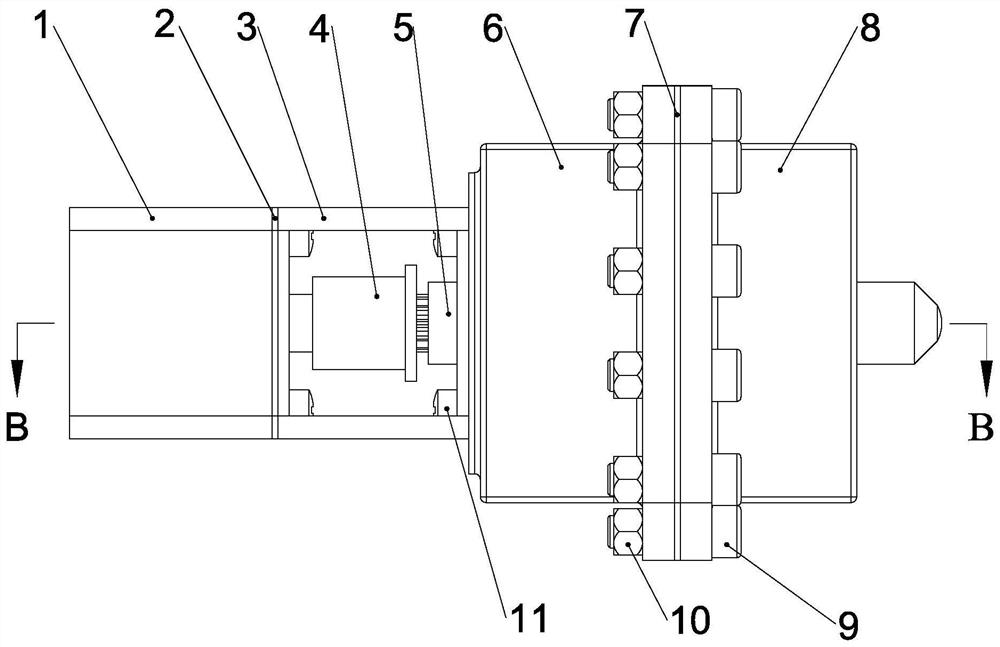

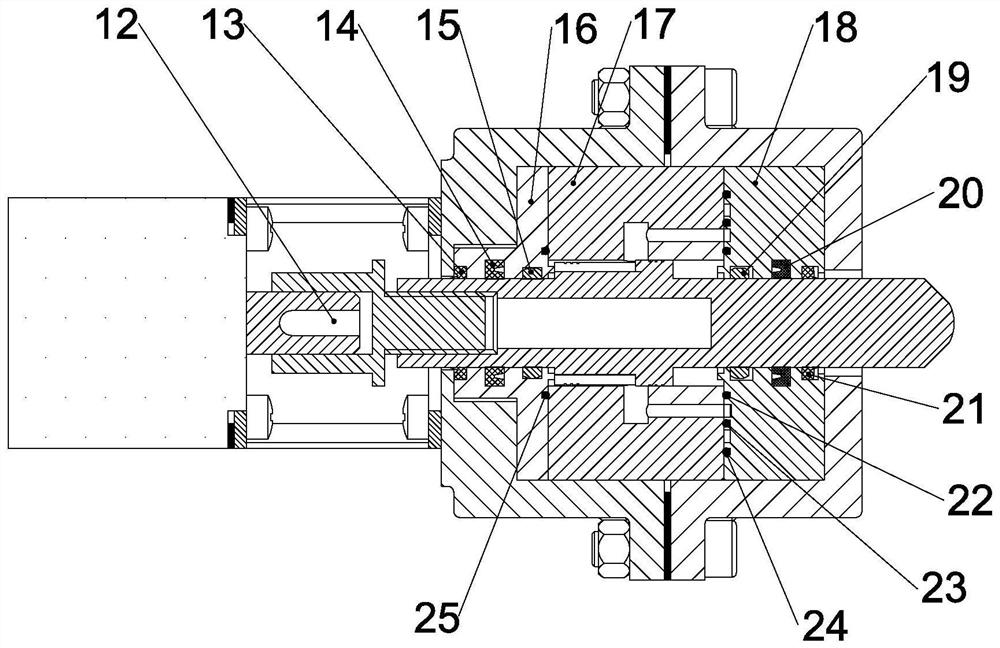

[0046] The high-frequency hydraulic vibration exciter of the present invention is suitable for hydraulic vibration systems, such as Figure 17 As shown, it includes DC motor controller C, motor C1, coupling C2, hydraulic pump C3, hydraulic oil tank C4, pilot relief valve C5, pressure gauge C6, pressure sensor C7, data acquisition system C8 and computer C9. The hydraulic pump C3 is a one-way quantitative hydraulic pump, and the main shaft of the electric motor C1 is coaxially connected with the main shaft of the hydraulic pump C3 through a coupling C2. The oil suction port of the hydraulic pump C3 is directly connected to the hydraulic oil tank C4, the outlet of the hydraulic pump C3 is bypassed in parallel with the pilot relief valve C5, the outlet of the pilot relief valve C5 is directly connected to the hydraulic oil tank C4, and the main oil circuit of the hydraulic pump C3 is directly connected to the high-frequency hydraulic excitation The high-pressure oil port Y13 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com