A high frequency hydraulic exciter

A hydraulic vibration exciter and high-frequency technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of high energy consumption systems, high energy consumption and low efficiency of hydraulic vibration excitation equipment , to achieve the effect of high axial movement frequency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

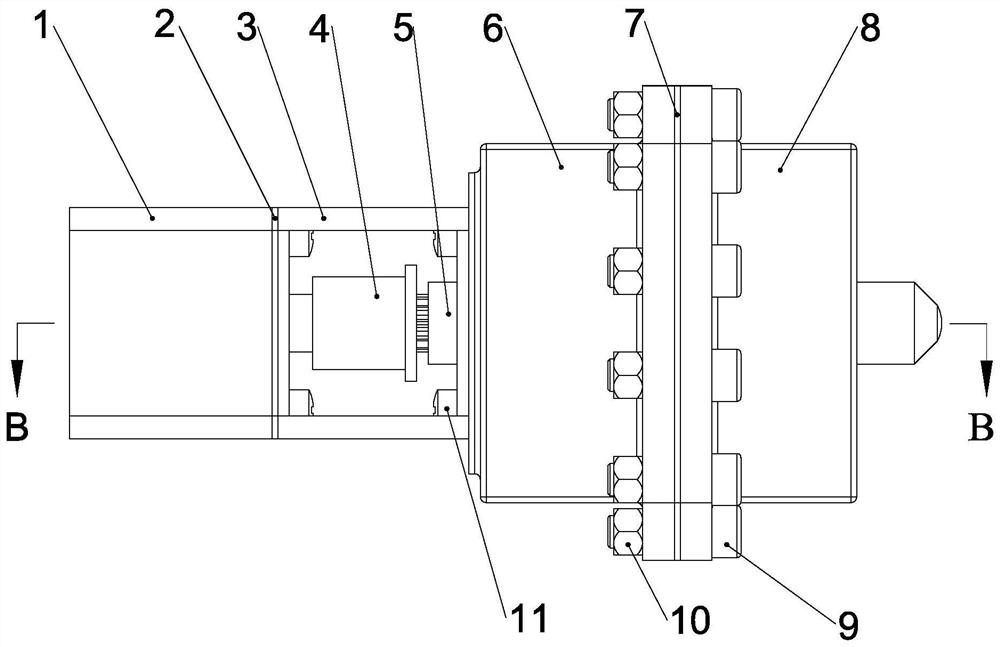

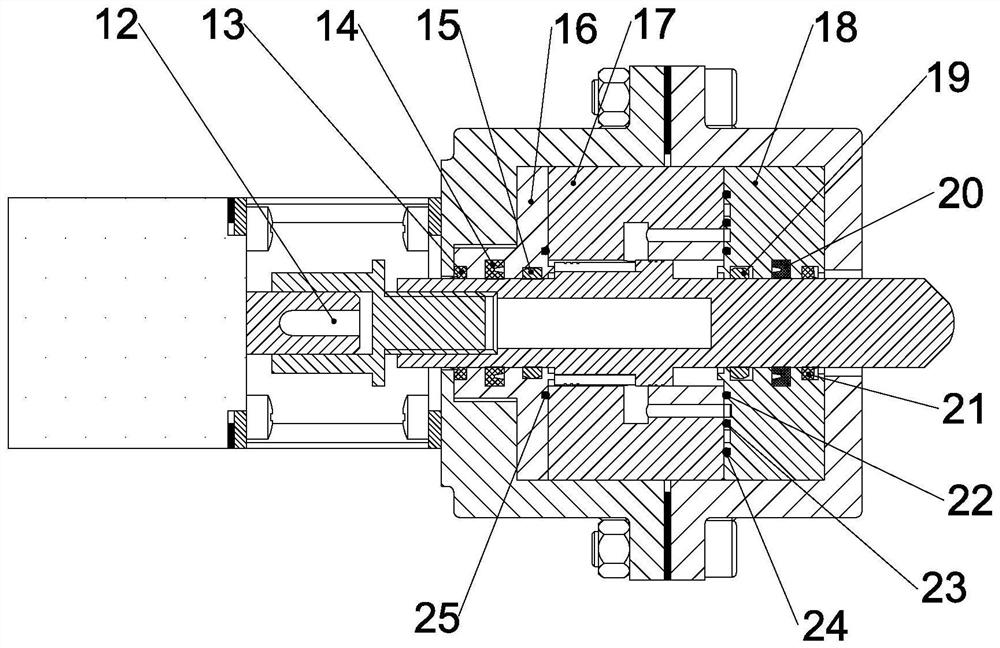

[0046] The high -frequency hydraulic treker of the present invention is suitable for the hydraulic vibration system, such as Figure 17 It shows that it includes DC motor controller C, electric motor C1, couplet C2, hydraulic pump C3, hydraulic fuel tank C4, pilot -type overflow valve C5, pressure gauge C6, pressure sensor C7, data collection system C8 and computer C9.所述液压泵C3为单向定量液压泵,所述电动机C1主轴通过联轴器C2与液压泵C3主轴同轴连接。 The oil -absorbing port of the hydraulic pump C3 is directly connected to the hydraulic fuel tank C4, the hydraulic pump C3 exit bypass parallel pioneer overflow valve C5, the pilot -type overflow valve C5 exit direct the hydraulic oil tank C4, and the hydraulic pump C3 main oil road direct high -frequency hydraulic excitement The high -pressure oil port Y13 of the vibrator, the low -voltage oil port Y14 of the high -frequency hydraulic excitator C4. The DC motor control C is used to output the control signal of the motor converter 1 on the high -frequency excitator. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com