Distance light guide module and vehicle lamp module thereof

A high-beam light guide and car lamp technology, which is applied in the field of car lights, can solve the problems of difficulty in avoiding stray light, difficulty in controlling the brightness change of low-beam light, and large volume of car lamp modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

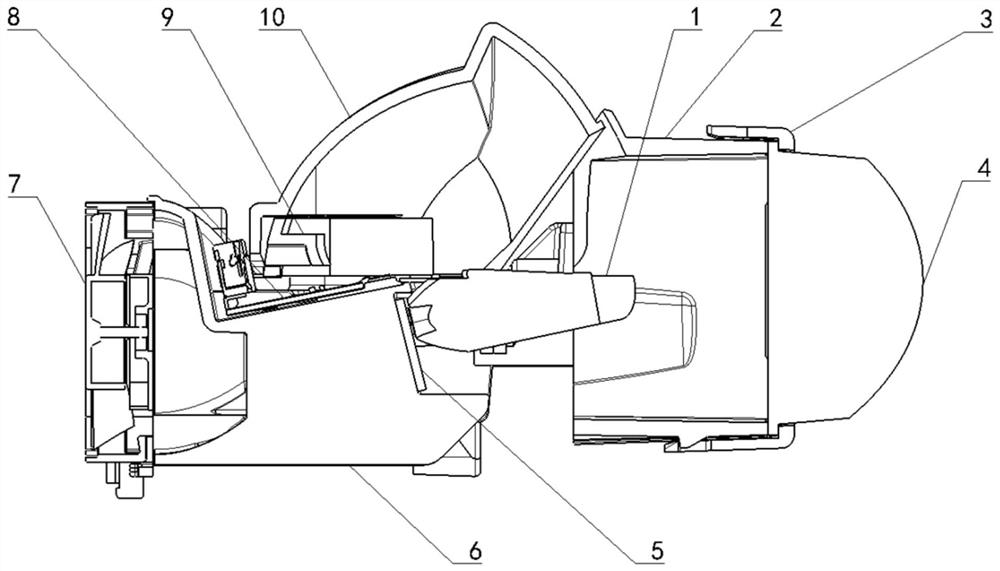

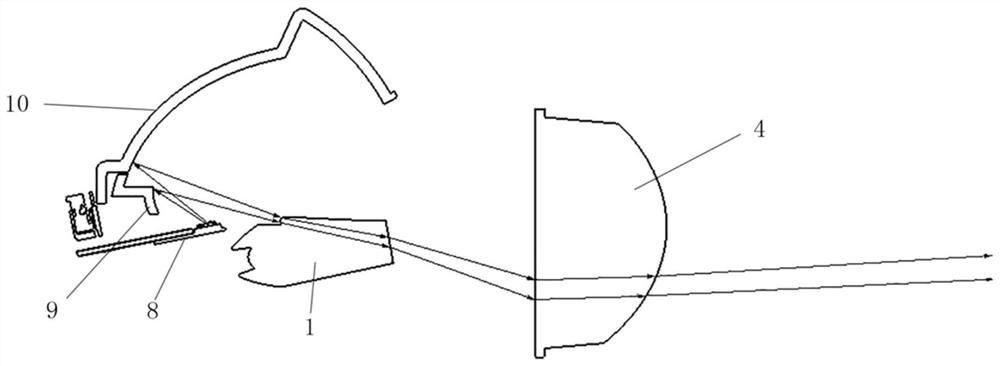

[0177] like figure 1 Shown is a far and near light integrated car light module, which is used for car lighting and placed in the car headlight. The far and near beam integrated car light module includes a high beam light guide module 1, a sunshade 2, a lens collar 3, a lens 4, a high beam LED circuit board 5, a radiator 6, a fan 7, a low beam LED circuit board 8, and a secondary mirror 9 and primary mirror 10. The primary reflector (10) and the secondary reflector (9) are used to form the low-beam light shape, wherein the primary reflector (10) can independently form the broadening of the low-beam light shape, and the existence of the secondary reflector (9) On the one hand, the number of light rays forming the low-beam light shape is increased to improve light efficiency; on the other hand, part of the light reflected by the secondary reflector (9) is used to form the low-beam light shape in zone III.

[0178] The overall size of the far and near beam integrated car light m...

Embodiment 2

[0190] Except following, other is as embodiment 1:

[0191] The position of the striae part of the light shape brightness adjustment structure in the III area corresponds to the B50L test point and / or the 50L test point and / or the P7 and P8 test points of the light shape in the III area. Reduce the brightness of the corresponding B50L test point and / or 50L test point in the low beam light pattern of the zone to greater than 0.1lx and less than 0.4lx respectively, and reduce the brightness of the P7 and P8 test points of the light pattern in zone III to greater than 0.1lx and less than 0.7 lx, at the same time, keep the brightness of the entire III area light shape at less than 0.7lx.

[0192] More specifically, the light pattern brightness adjustment structure in the III area reduces the brightness of the corresponding B50L test point in the low beam light pattern in the III area on the light screen to greater than 0.2lx and less than 0.3lx, and the corresponding P7, The brig...

Embodiment 3

[0195] Except following, other is as embodiment 1:

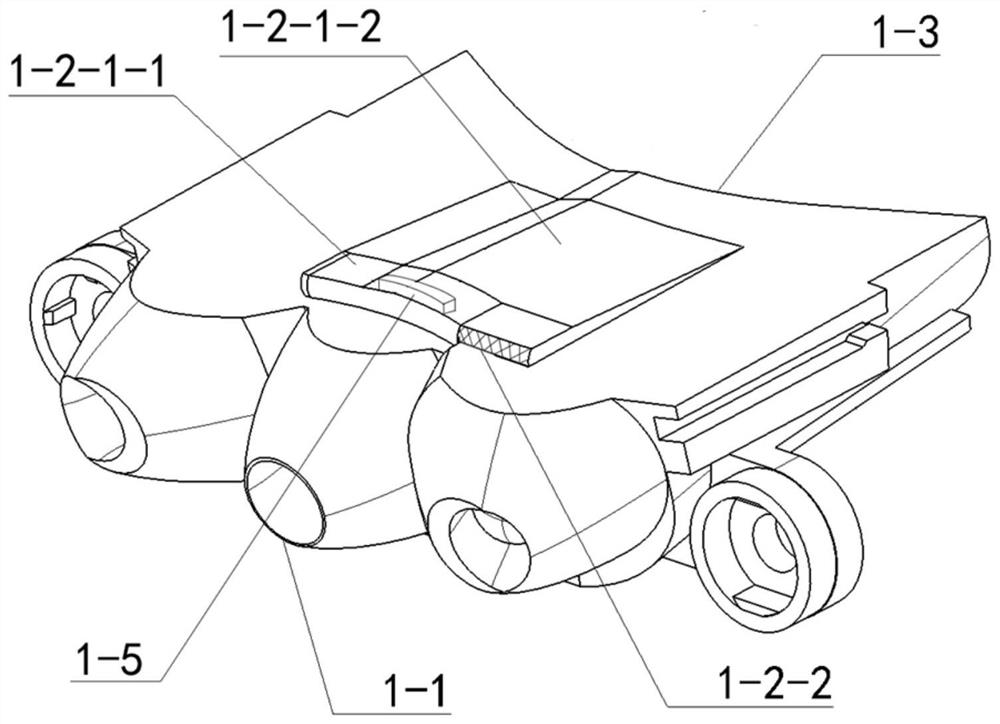

[0196] like figure 2 , as shown in 8 and 9, the light shape broadening formation structure (1-2-1) includes the end portion of the light shape broadening formation structure 1-2-1-1 in the III zone, and the light shape transition zone structure 1-2-1 in the III zone -2. The light shape transition zone structure 1-2-1-2 in zone III is triangular in cross-section along the light axis, so that the height of the structure formed by widening the light shape in zone III gradually decreases to a continuous transition with no drop from the upper surface of the high beam light guide module. This facilitates light shape diffusion, improves light efficiency, and provides a clear light shape in Zone III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com