A drying device for resin processing

A drying device and resin processing technology, applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of reducing drying efficiency, incomplete drying, inconvenient use, etc., to ensure drying quality, avoid The effect of blocking and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

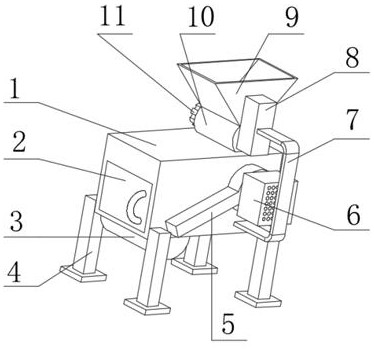

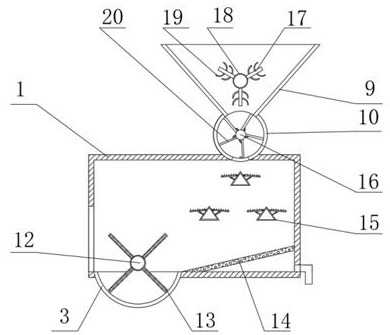

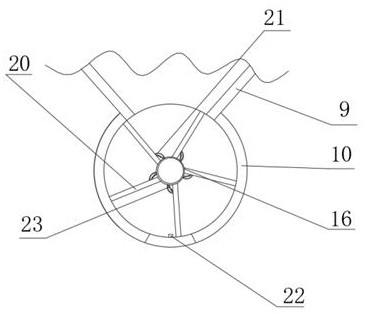

[0028] refer to Figure 1-4 , a drying device for resin processing, comprising a drying shell 1, the top outer wall of the drying shell 1 is plugged with a blanking shell 10, and the top outer wall of the blanking shell 10 is equipped with a hopper 9, the drying shell The inner walls of both ends of the body 1 are equipped with triangular housings 15 equidistantly distributed, and the outer walls of both sides of the triangular housing 15 are provided with air outlets 27 equidistantly distributed, and the outer wall of the bottom of the drying housing 1 is equipped with an arc-shaped housing. 3. The inner walls of both ends of the arc-shaped housing 3 are rotatably connected to the same hollow shaft 12, the outer wall of the hollow shaft 12 is equipped with hollow housings 13 equidistantly distributed, and the joint between the hollow shaft 12 and the hollow housing 13 is provided with an opening. Hollow housing 13 is provided with equidistant air diffuser holes on the outside...

Embodiment 2

[0032] refer to Figure 1-5 , a drying device for resin processing, which also includes a drying shell 28 and an air pump 30 respectively installed on the other side of the top outer wall of the drying shell 1, and a first connecting pipe is installed at the input end of the air pump 30, and the first connecting pipe The other end of the pipe extends to the inside of the drying shell 1, and a second connecting pipe is installed at the output end of the air pump 30, and the other end of the second connecting pipe extends to the inside of the drying shell 28, and the outer wall of one side of the drying shell 28 is plugged with a third connecting pipe. The other end of the third connecting pipe extends to the inside of the drying shell 1, and the other end of the third connecting pipe is equipped with an arc-shaped air outlet pipe 29, and the outer wall of the arc-shaped air outlet pipe 29 is equipped with equidistantly distributed air jets. The same desiccant storage box 31 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com