Combustion performance test system and test method of a mixed air gas

A test system and gas combustion technology, which is applied in the direction of chemical analysis by combustion, measuring devices, and gas mixture analysis, can solve the problems of unclear influence on the gas production process and the inability to accurately control the hydrocarbon content of mixed air gas, and achieve accurate data The effect of supporting and guaranteeing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] For ease of understanding, the specific structure and workflow of the present invention is further described herein:

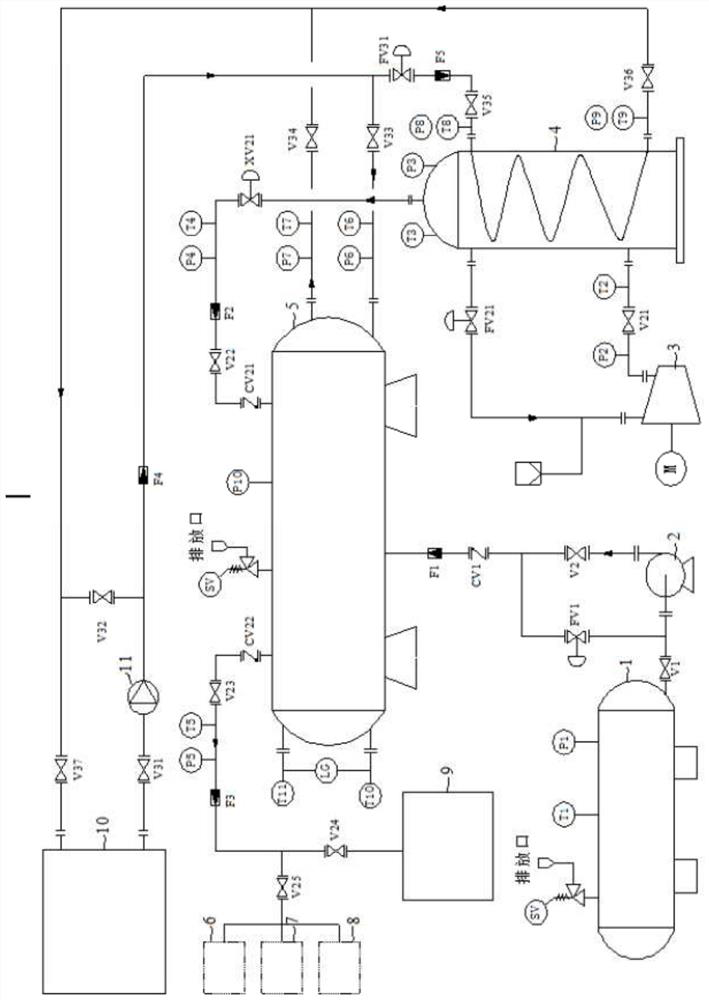

[0036] Specific embodiments of the present invention may refer to Figure 1 As shown, the entire system consists of a mixed hydrocarbon circuit, an air circuit, a thermal circulation circuit, and a test line, where:

[0037] The mixed hydrocarbon circuit comprises a hydrocarbon material tank 1 connected sequentially through the pipeline, manual valve V1, hydrocarbon circulation pump 2, manual valve V2, check valve CV1, flowmeter F1, the outlet of the flowmeter F1 is connected to the mixed empty gas storage tank 5; at the same time, the regulating valve FV1 is bridged between the manual valve V2 outlet and the manual valve V1 outlet to form a circuit. The hydrocarbon tank 1 is arranged with thermometer T1 and the manometer P1 for measuring internal temperature and pressure.

[0038]The air circuit comprises a fan 3, a manometer P2, a manual valve V21, a therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com