Cable with Z-shaped shielding layer

A technology of shielding tape and conductive layer, applied in the direction of power cable, insulated cable, power cable with shielding layer/conductive layer, etc., can solve the problems of gap and discontinuity in the shielding layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

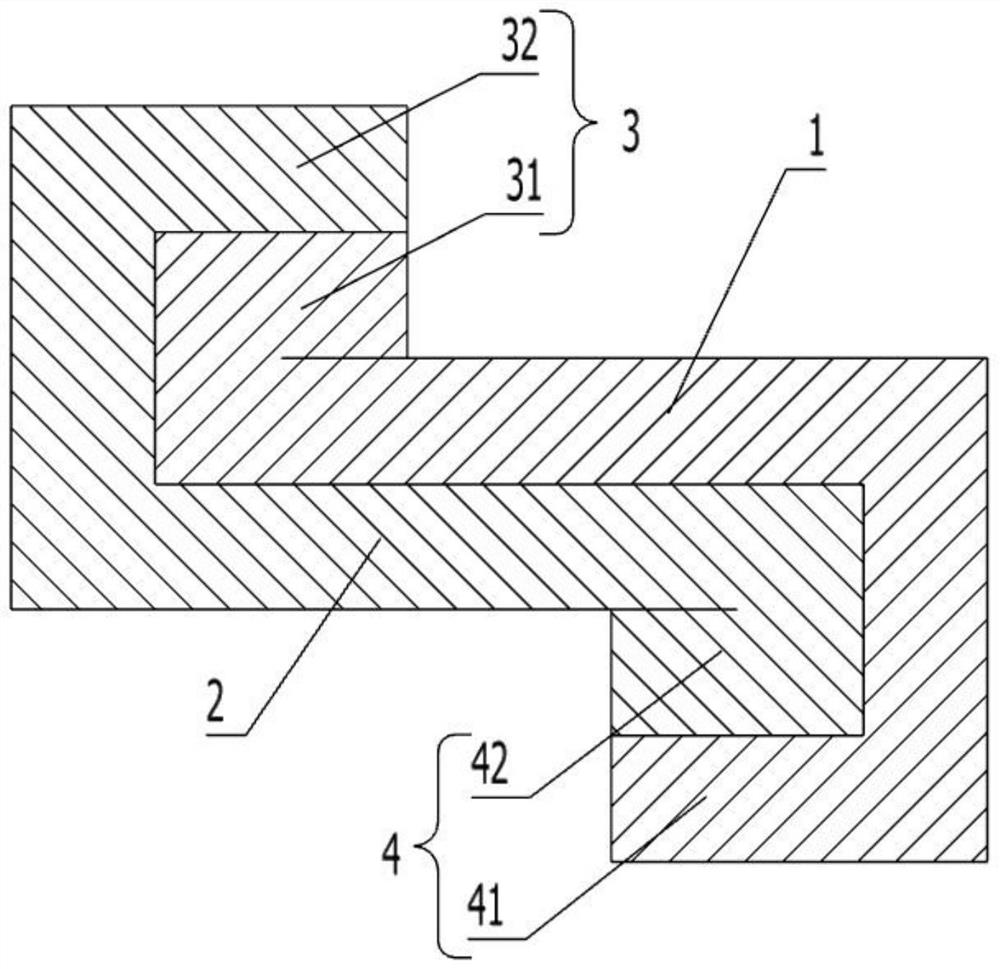

[0066] figure 1 It is a schematic cross-sectional view of a shielding tape in this application, image 3 It is a schematic diagram of a cable structure in this application, image 3 yes figure 1 Schematic diagram of the application scenario of the shielding tape in . refer to figure 1 and image 3 This embodiment provides a shielding tape, which is used as a shielding layer of a cable, and includes a first conductive layer 1 and an insulating layer 2, and the first conductive layer 1 and the insulating layer 2 can be fixed by glue. Among them, in this embodiment, the shielding tape is provided with a first fold 3 and a second fold 4 on both sides of the shielding tape, the first fold 3 is formed by folding the shielding tape toward the first conductive layer 1 side, and the second fold Edge 4 is formed by folding the shielding tape toward the insulating layer 2, making the shielding tape Z-shaped. When the shielding tape is wrapped around the outside of the core wire, the...

Embodiment 2

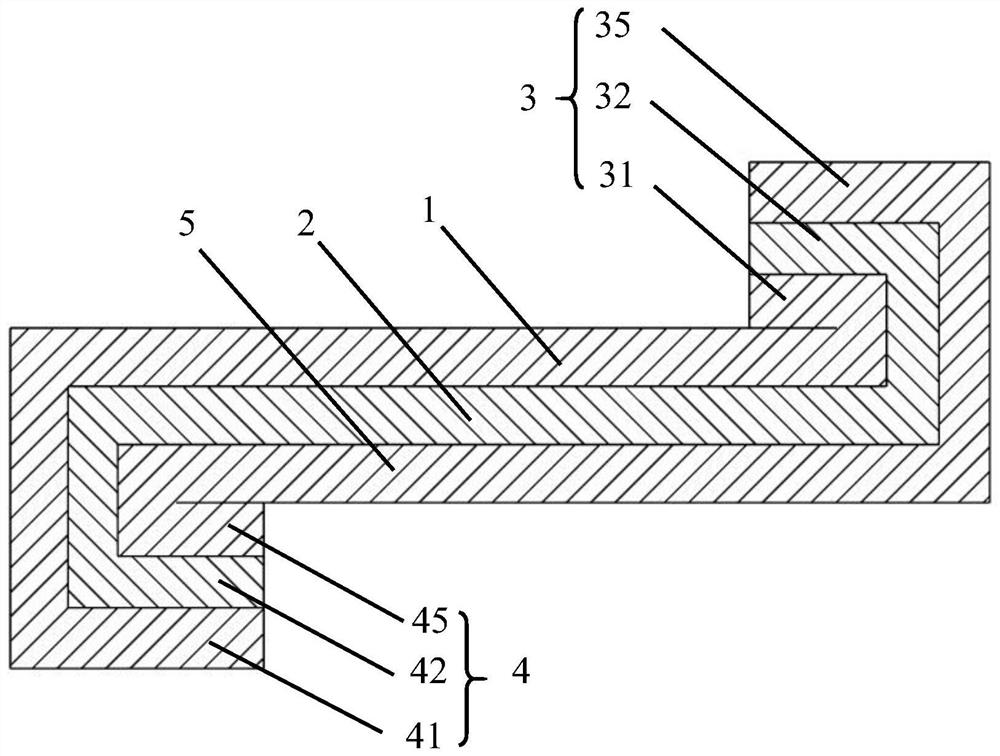

[0071] figure 2 is a schematic cross-sectional view of another shielding tape in this application, image 3 It is a schematic diagram of a cable structure in this application, image 3 yes figure 2 Schematic diagram of the application scenario of the shielding tape in . refer to figure 2 and image 3 , this embodiment provides a shielding tape, including a first conductive layer 1, an insulating layer 2 and a second conductive layer 5, the first conductive layer 1 and the second conductive layer 5 are arranged on both sides of the insulating layer 2, the first The conductive layer 1 and the insulating layer 2 , and the second conductive layer 5 and the insulating layer 2 can be fixed by glue. Among them, in this embodiment, the shielding tape is provided with a first folded edge 3 and a second folded edge 4 on both sides of the shielding tape. The first folded edge 3 is formed by folding the shielding tape toward the first conductive layer 1 side. The edge 4 is formed...

Embodiment 3

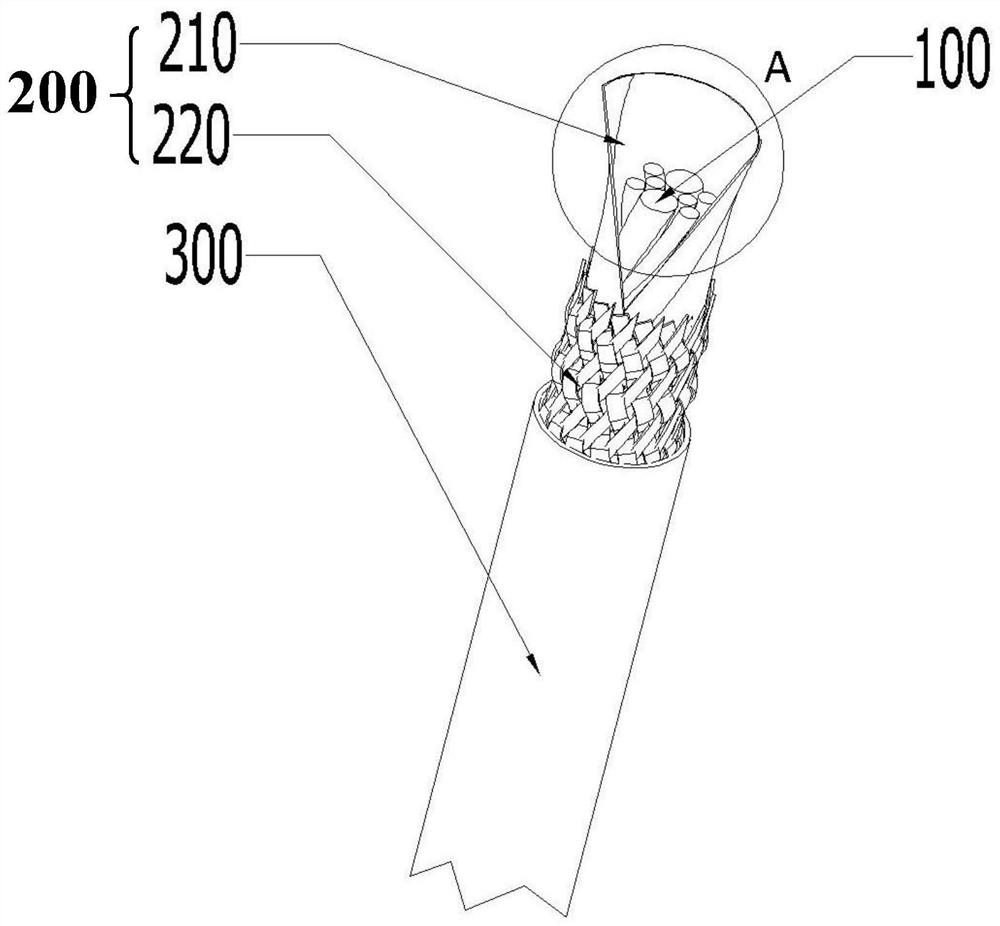

[0076] image 3 It is a schematic diagram of a cable structure in this application, Figure 4 yes image 3 Partial enlarged view of A, Figure 5 It is a schematic cross-sectional structure diagram of this embodiment.

[0077] refer to Figure 3-5 This embodiment provides a cable, including a core wire 100, a shielding body 200 and a sheath layer 300 arranged outside the core wire 100, and the shielding body 200 further includes a shielding layer 210 and a braided mesh 220. Wherein, the shielding layer 210 is made of a shielding tape, preferably an aluminum foil tape, which can be single-sided aluminum foil or double-sided aluminum foil. The shielding layer 210 is wrapped around the outside of the core wire 100 by winding or wrapping, and has an inner edge 211 and an outer edge 212 at its joint, the inner edge 211 is turned outward, and the outer edge 212 is turned outward.

[0078] In this embodiment, the inner edge 211 and the outer edge 212 are in contact with each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com