LED packaging process method

A technology of LED packaging and process method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor heat dissipation effect and short service life, and achieve the effects of easy control, good durability, and improved light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

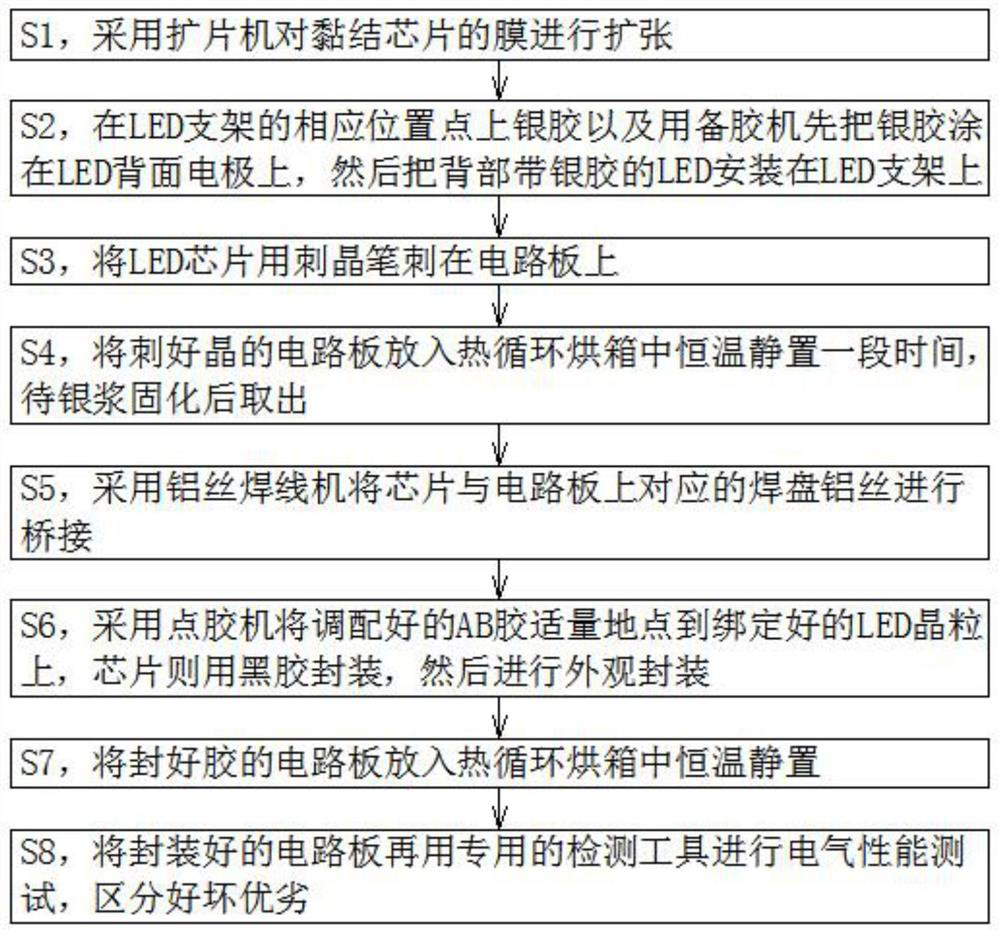

[0027] Embodiment 1: a kind of LED encapsulation process method, comprises the following steps:

[0028] S1, using the expansion machine to expand the film of the bonded chip;

[0029] S2, apply silver glue on the corresponding position of the LED bracket and apply the silver glue on the back electrode of the LED with a glue preparation machine, and then install the LED with the silver glue on the back of the LED bracket;

[0030] S3, stabbing the LED chip on the circuit board with a spine pen;

[0031] S4, put the thorned circuit board into a thermal cycle oven at a constant temperature and let it stand for a period of time, and take it out after the silver paste is solidified;

[0032] S5, using an aluminum wire bonding machine to bridge the chip with the corresponding pad aluminum wire on the circuit board;

[0033] S6, using a glue dispenser to place an appropriate amount of the prepared AB glue on the bound LED die, and the chip is packaged with black glue, and then the...

Embodiment 2

[0041] Embodiment 2, an LED encapsulation process method, includes the following steps:

[0042] S1, using the expansion machine to expand the film of the bonded chip;

[0043] S2, apply silver glue on the corresponding position of the LED bracket and apply the silver glue on the back electrode of the LED with a glue preparation machine, and then install the LED with the silver glue on the back of the LED bracket;

[0044] S3, stabbing the LED chip on the circuit board with a spine pen;

[0045] S4, put the thorned circuit board into a thermal cycle oven at a constant temperature and let it stand for a period of time, and take it out after the silver paste is solidified;

[0046] S5, using an aluminum wire bonding machine to bridge the chip with the corresponding pad aluminum wire on the circuit board;

[0047] S6, using a glue dispenser to place an appropriate amount of the prepared AB glue on the bound LED die, and the chip is packaged with black glue, and then the appeara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com