A kind of high-capacity artificial graphite negative electrode material for lithium-ion power battery and preparation method thereof

A technology of artificial graphite negative electrode and power battery, which is applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problem of low capacity of artificial graphite, achieve high commercial value, increase added value, and realize the effect of rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

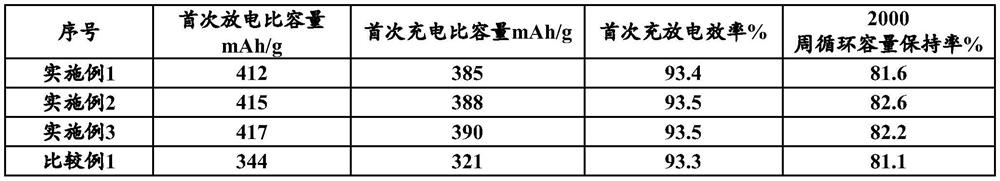

Examples

preparation example Construction

[0039] The preparation method of the present invention will be described in further detail below with reference to specific examples. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies implemented based on the above content of the present invention are covered within the intended protection scope of the present invention.

[0040] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents, materials, etc. used in the following examples can be obtained from commercial sources unless otherwise specified.

[0041] The siliconizing agent used in the following examples is composed of 3-4wt% sodium fluoride, 10-12wt% silicon powder and 84-86wt% alumina.

[0042] The artificial graphite block used in the following examples comes from the leftover material...

Embodiment 1

[0044]The siliconizing agent: water: polyvinyl alcohol is mixed evenly in a weight ratio of 15:80:3 to prepare a siliconizing slurry, and the siliconizing slurry is coated on the surface of the artificial graphite block by a dip coating method, and then dried; The dried graphite block was placed in a high-temperature furnace, heated to 1000°C for 1 hour under a vacuum of -0.02MPa, taken out under air cooling to room temperature, cleaned with ultrasonic waves for 0.5 hours, and then blown dry with cold air. Then it is crushed, classified and shaped in an impact pulverizer to obtain the average particle size D. 50 It is 16μm artificial graphite powder. Mix pitch and artificial graphite micropowder at a weight ratio of 1:20, treat under the protection of inert gas at a temperature of 1000°C for 2 hours, cool to room temperature, and then disperse, sieve, and demagnetize to obtain a product.

Embodiment 2

[0046] The siliconizing agent: water: starch is mixed evenly in a weight ratio of 18:85:3 to prepare a siliconizing slurry, and the siliconizing slurry is coated on the surface of the artificial graphite block by spraying, and then dried; The graphite block was placed in a high-temperature furnace, heated to 1100°C under a vacuum of -0.06MPa for 0.5 hours, air-cooled to room temperature, taken out, cleaned with ultrasonic waves for 1 hour, and dried with cold air. Then, it is crushed, classified and shaped in an airflow vortex mill to obtain an average particle size D. 50 It is 18μm artificial graphite powder. Mix pitch and artificial graphite micropowder at a weight ratio of 1:30, treat at 800°C for 2 hours under the protection of inert gas, cool to room temperature, disperse, sieve and demagnetize to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com