Arrangement structure of electric heating plate

A technology of electric heating plate and layout structure, which is applied in the direction of electric heating device, ohmic resistance heating, ohmic resistance heating parts, etc., which can solve the problems of large power consumption, long processing period, and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

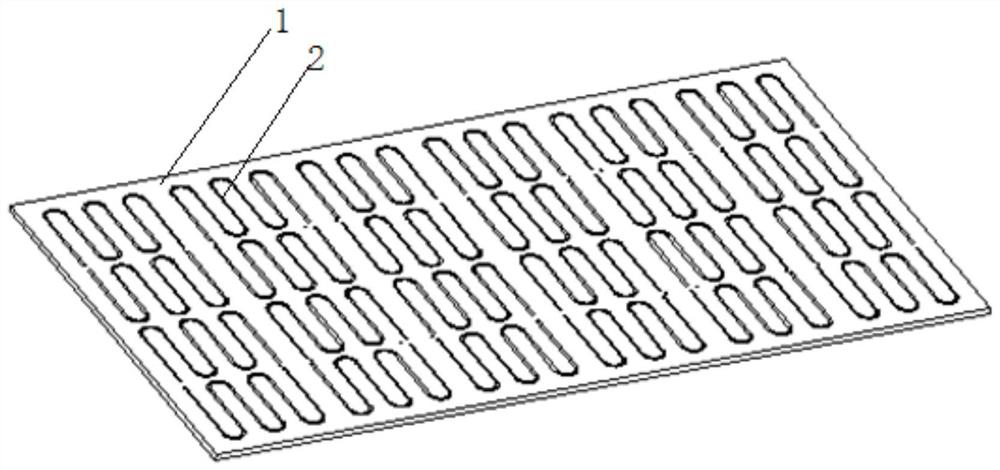

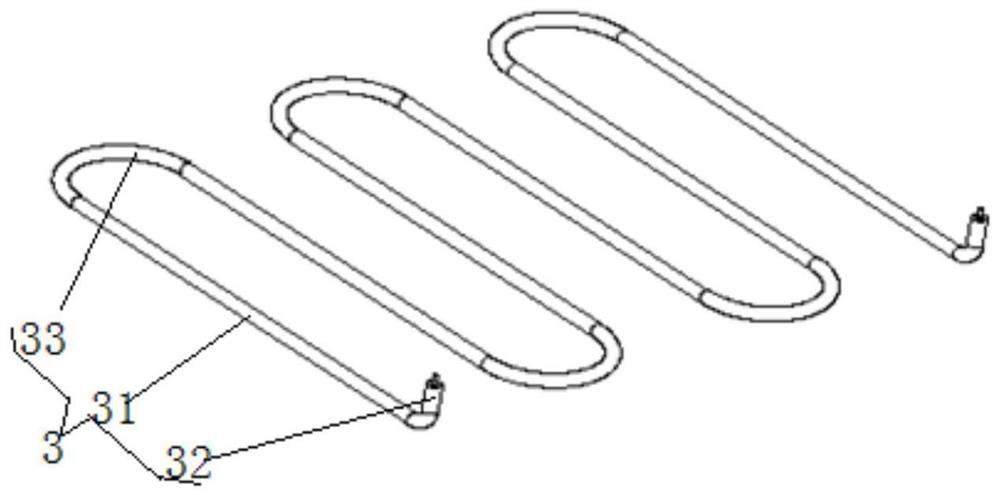

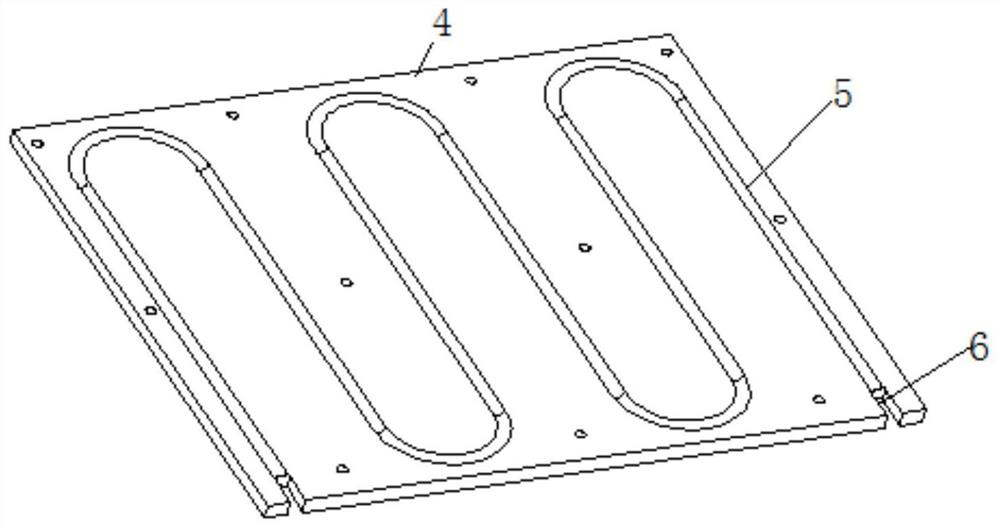

[0025] like Figure 1 to Figure 7 The arrangement structure of the electric heating plate shown includes a heating plate 1, and the back of the heating plate 1 is provided with multiple rows of first serpentine grooves 2 in an array; each of the first serpentine grooves 2 is equipped with a serpentine Rectangular column heating tube 3; the top surface of each of the first serpentine grooves 2 is fixed with a cast aluminum gland 4 by screws; the cast aluminum gland 4 is provided with a second serpentine groove facing the first serpentine groove 5; the serpentine rectangular column heating tube 3 is clamped in the cavity formed by the first serpentine groove and the second serpentine groove; two open grooves 6 are opened on one side of the cast aluminum gland 4; the snake The two ends of the right-angled line column heating tube 3 are drawn from the open groove 6; the heating plate 1 is provided with a temperature sensor 7 at the first serpentine groove in the adjacent row; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com