Full-servo high-speed production line for elastic ear band planar masks

A production line and mask technology, applied in the direction of clothing, clothing, sewing tools, etc., can solve the problems of tight ears, small contact area, uneven quality residuals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

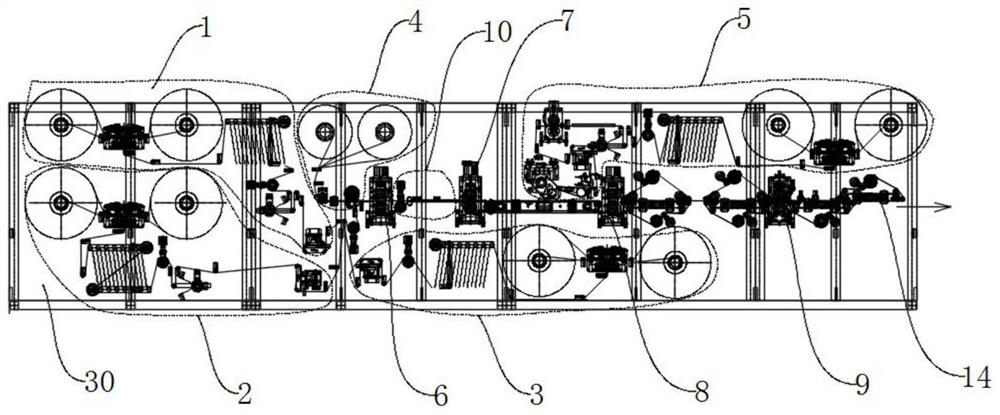

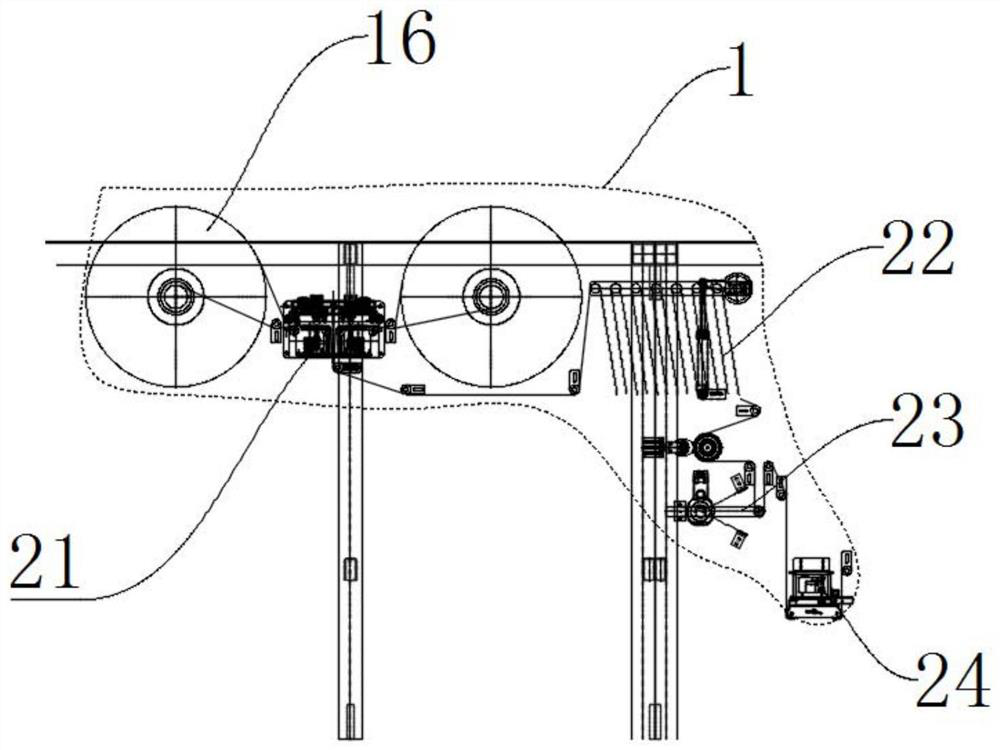

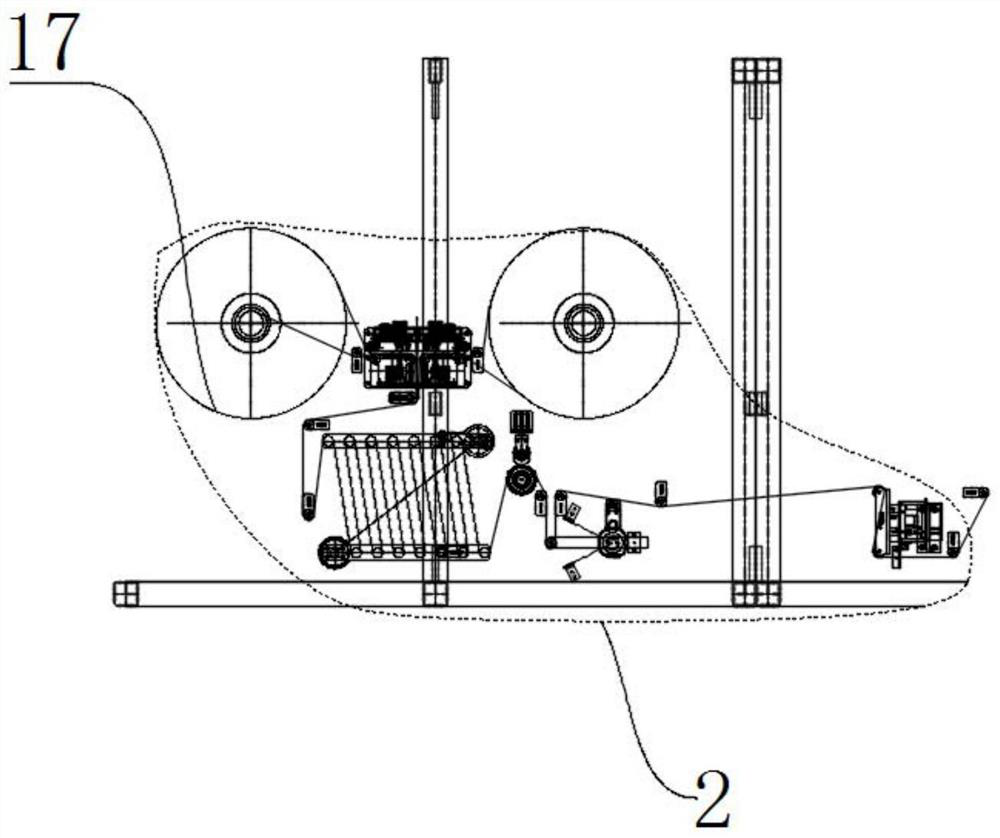

[0039] refer to Figure 1 to Figure 11 The mask produced by the full servo high-speed production line of the elastic earband flat mask is composed of five parts, including the earband 31, the outer layer 32, the skin-friendly layer 33, and the melt-blown cloth layer 34. During production, the outer layer, the melt-blown cloth Layer, skin-friendly layer, and ear straps are stacked in sequence and fixed by hot-pressing connections, and the formed mask ear straps are in a folded state.

[0040] A full-servo high-speed production line for elastic earband flat masks, including a skin-friendly layer feeding mechanism 1, a melt-blown cloth feeding mechanism 2, an outer layer feeding mechanism 3, a nose bridge strip feeding mechanism 4, and an inner lining material feeding mechanism 5 , embossing mechanism 6 on both sides of the mask, embossing mechanism 7 at both ends of the mask, pressure point mechanism 8 for ear straps, mask forming and cutting mechanism 9, bellows transmission co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap