Centrifuge tube with double-layer structure

A double-layer structure, centrifuge tube technology, applied in the field of centrifuge tubes, to achieve the effect of eliminating biological safety hazards, preventing pollution, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

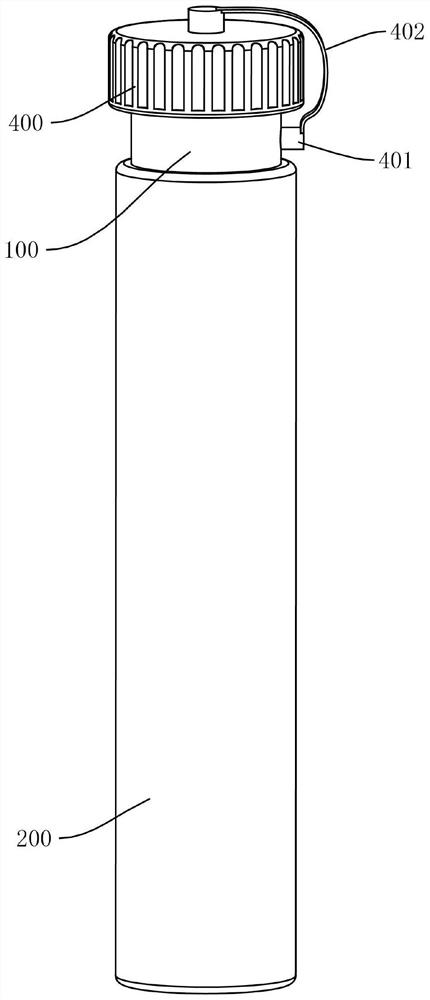

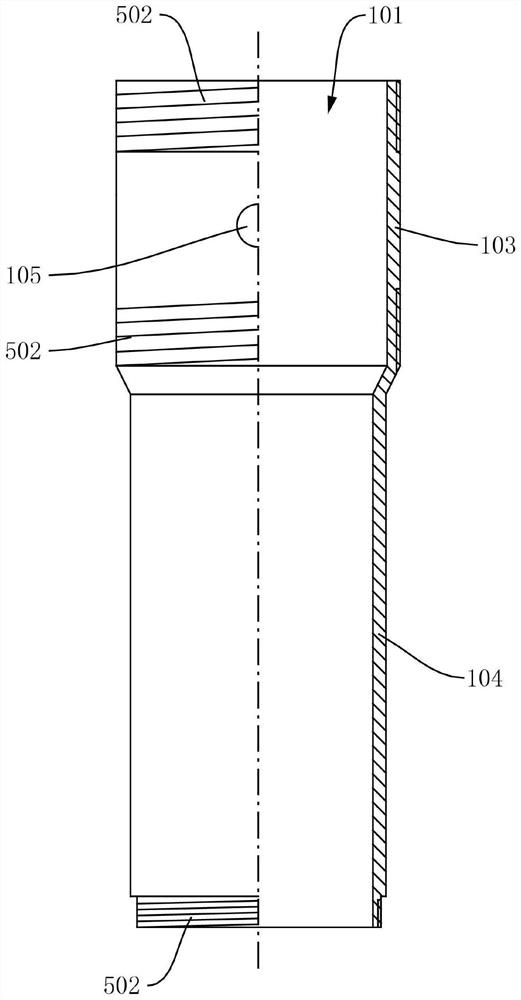

[0057] see Figure 1-Figure 14 , a double-layer centrifuge tube is provided in this embodiment, including an inner tube 100 and an outer tube 200, wherein the inner tube 100 is provided with a first internal cavity 101 and a first opening, and the first opening communicated with the first internal cavity 101,

[0058] The outer tube 200 is provided with a second internal cavity 201 and a second opening, the second opening communicates with the second internal cavity 201,

[0059] Such as figure 1 , Figure 8 , Figure 11 As shown, the outer tube 200 is sleeved on the outside of the inner tube 100, and an annular sealing ring 300 is arranged between the outer tube 200 and the inner tube 100, and the annular sealing ring 300 is fixed on the outer tube 200 for realizing sliding sealing. And form a closed cavity between the outer tube 200 and the inner tube 100, the inner tube 100 is provided with a communication hole 102 for communicating with the first inner cavity 101 and t...

Embodiment 2

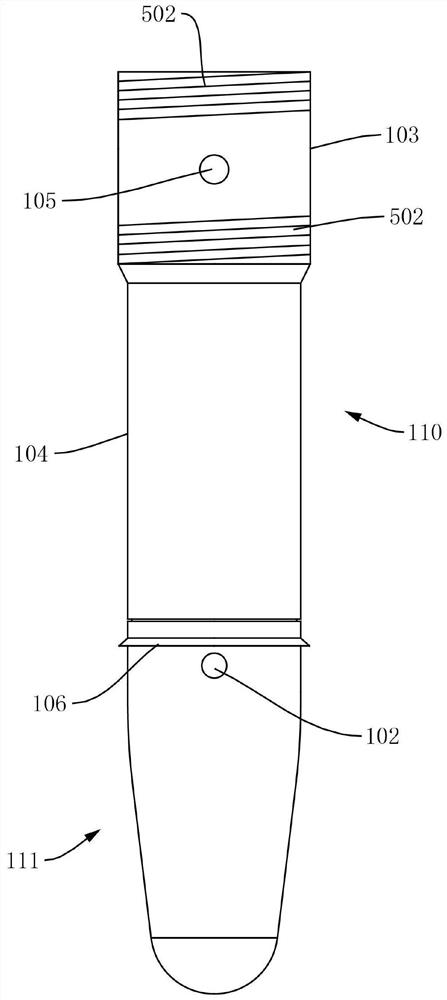

[0087] In order to facilitate the removal of the sediment at the lower part of the inner tube 100 after centrifugation, the main difference between this embodiment 2 and the above-mentioned embodiment 1 is that in the centrifuge tube provided by this embodiment, the inner tube 100 includes an upper tube section 110 (the upper pipe section 110 can be made of the first pipe section 103 and the second pipe section 104 described in embodiment 1) and the lower pipe section 111, the lower end of the upper pipe section 110 is integrally connected with the upper end of the lower pipe section 111 by screw thread , and the outer diameters of the upper pipe section 110 and the lower pipe section 111 are the same, such as Figure 2-Figure 4 shown;

[0088] The lower end of the lower pipe section 111 is closed, and the communicating hole 102 and the first restricting member 106 are respectively configured in the lower pipe section 111, such as Figure 4 as shown,

[0089] The first openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com