Magnet processing equipment and processing method

A technology of processing equipment and magnets, applied in metal processing equipment, other manufacturing equipment/tools, metal processing machinery parts, etc., can solve problems such as affecting slicing efficiency and inconvenient blank fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

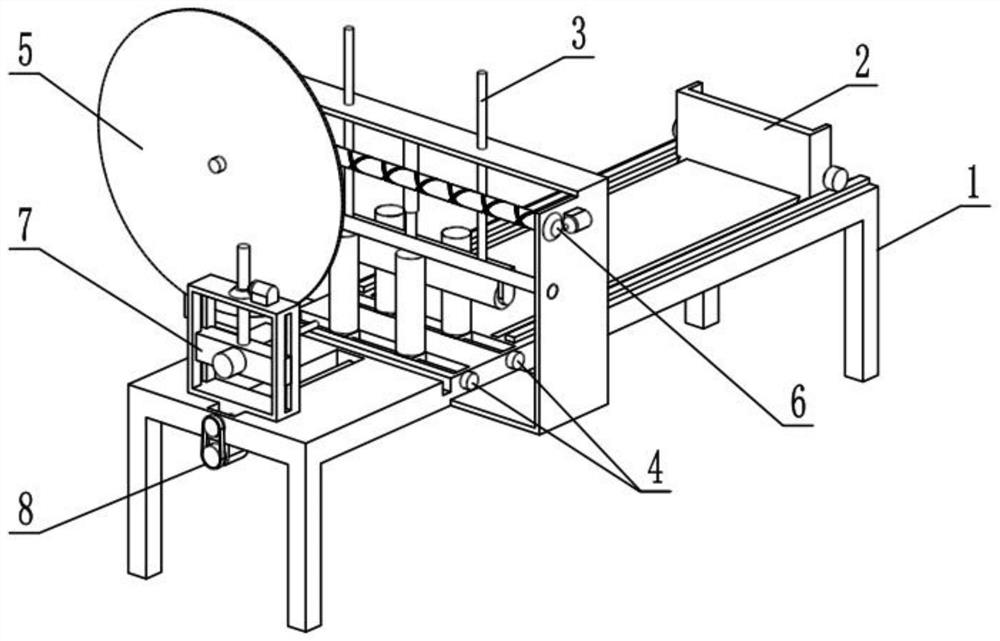

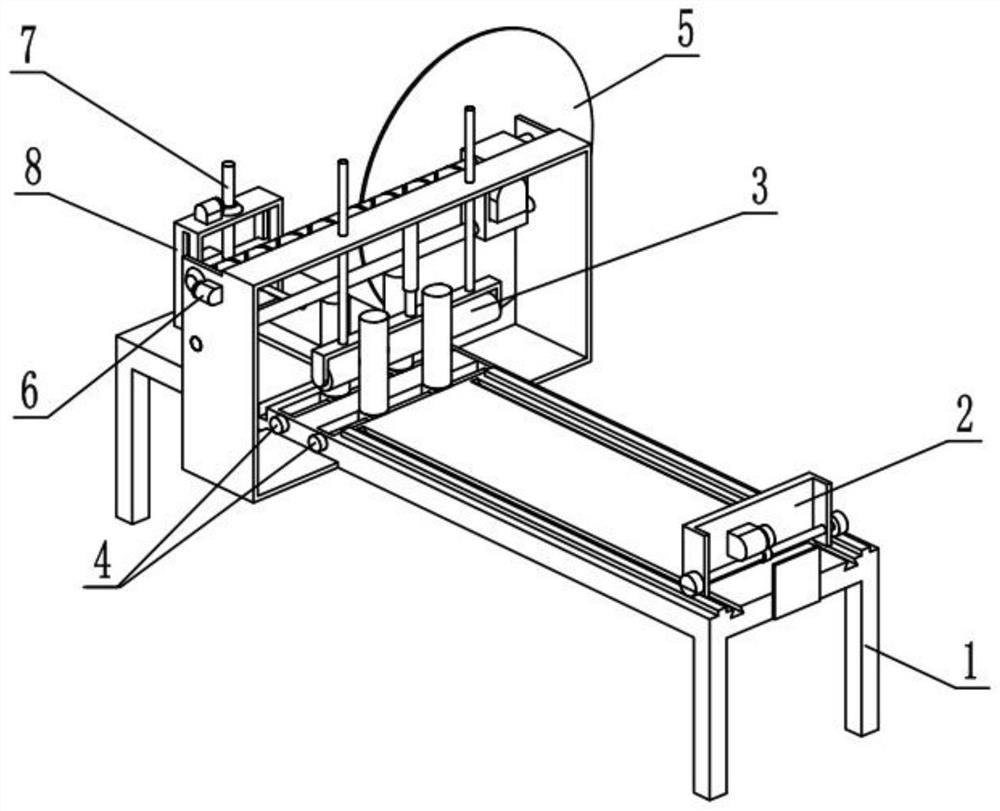

[0035] Such as Figure 1-10 As shown, a magnet processing equipment includes a support frame 1, a pushing mechanism 2, an upper clamping mechanism 3, a side end clamping mechanism 4, a cutting mechanism 5, a cutting moving mechanism 6, a drilling mechanism 7 and a drilling feeding mechanism 8. It is characterized in that: the push mechanism 2 is slidably connected to the rear end of the support frame 1, the upper clamping mechanism 3 is slidably connected to the upper end of the support frame 1, and the side clamping mechanism 4 is provided with Two, two side end clamping mechanisms 4 are all connected on the support frame 1, the two side end clamping mechanisms 4 are located at the front and rear ends of the top clamping mechanism 3, and the cutting moving mechanism 6 is connected to the support frame 1 The upper end of the upper end, the cutting mechanism 5 is fixedly connected to the cutting moving mechanism 6, the cutting mechanism 5 is located in front of the two side cla...

specific Embodiment approach 2

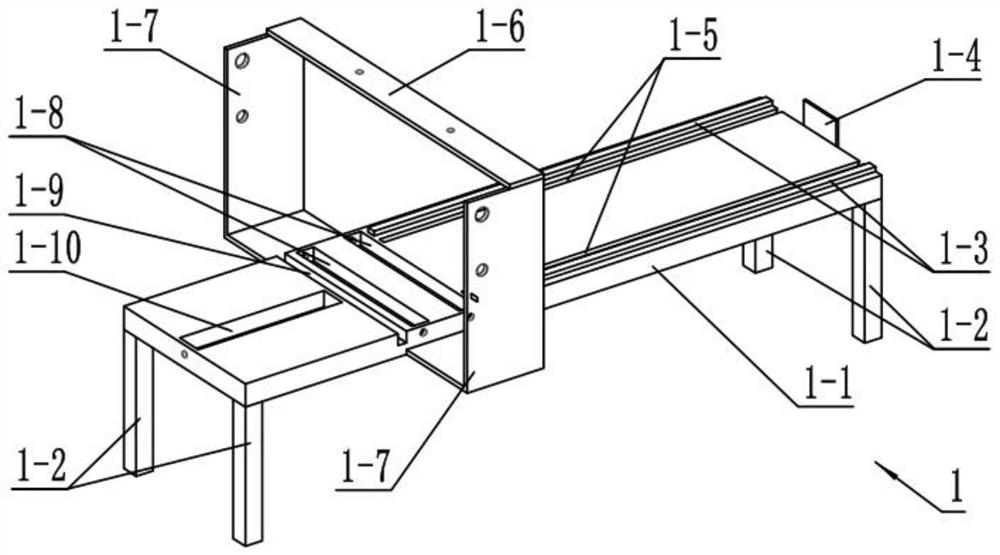

[0038] Such as Figure 1-10 As shown, the support frame 1 includes a support main board 1-1, a leg 1-2, a rack 1-3, a limit baffle 1-4, a push slideway 1-5, an upper horizontal plate 1-6, Side support plate 1-7, clamping slideway 1-8, cutter groove 1-9 and drilling slideway 1-10, supporting legs 1-2, rack 1-3 is provided with two, and the two racks 1-3 are fixedly connected to the support main board 1-1 in the front and rear direction, and the limit baffle 1-4 is fixedly connected to the rear end of the support main board 1-1, pushing the slideway 1-5 is provided with two, and the two pushing slideways 1-5 are arranged on the support main board 1-1 in the front and rear directions, and the clamping slideway 1-8 is provided with two, two clamping slideway 1-8 and The cutter grooves 1-9 are set on the support main board 1-1 in the left and right directions, the clamping slideway 1-8 at the rear end is located in front of the two pushing slideways 1-5, and the cutter groove 1-9 ...

specific Embodiment approach 3

[0040] Such as Figure 1-10 As shown, the push mechanism 2 includes a push plate 2-1, a push motor 2-2, a push side plate 2-3, a push shaft 2-4, a push gear 2-5 and a push slider 2-6, and the push plate The left and right ends of 2-1 are provided with push side plates 2-3, and the push shaft 2-4 is rotatably connected to the two push side plates 2-3, and both ends of the push shaft 2-4 are provided with push gears 2- 5. The push motor 2-2 is fixedly connected to the rear end face of the push plate 2-1, the push motor 2-2 is connected to the push shaft 2-4, and there are two push sliders 2-6, two push sliders 2- 6 are fixedly connected to the lower end of the push plate 2-1, and the two push sliders 2-6 are slidably connected in the two push slideways 1-5 respectively, and the two push gears 2-5 are connected to the two racks 1-5 respectively. 3 meshing transmission connection;

[0041] Start the push motor 2-2 to drive the push shaft 2-4 to rotate, and the push plate 2-1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com