Modified wood, method of manufacturing same, and musical instrument

A manufacturing method and wood technology, which can be used in wood processing utensils, musical instruments, stringed instruments, etc., and can solve problems such as wood formaldehyde odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

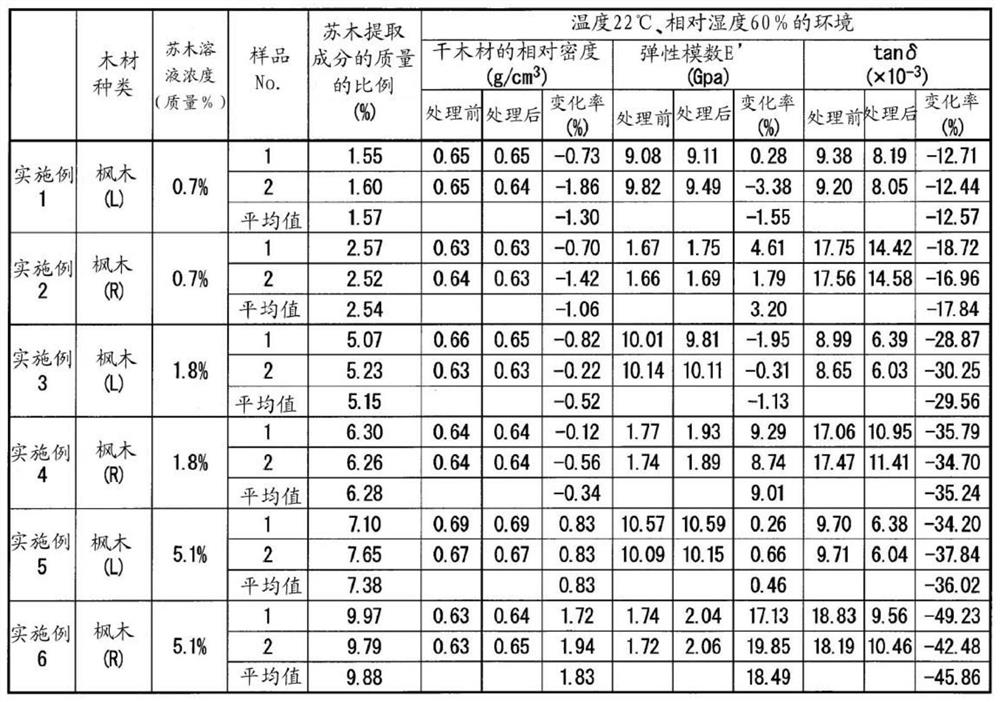

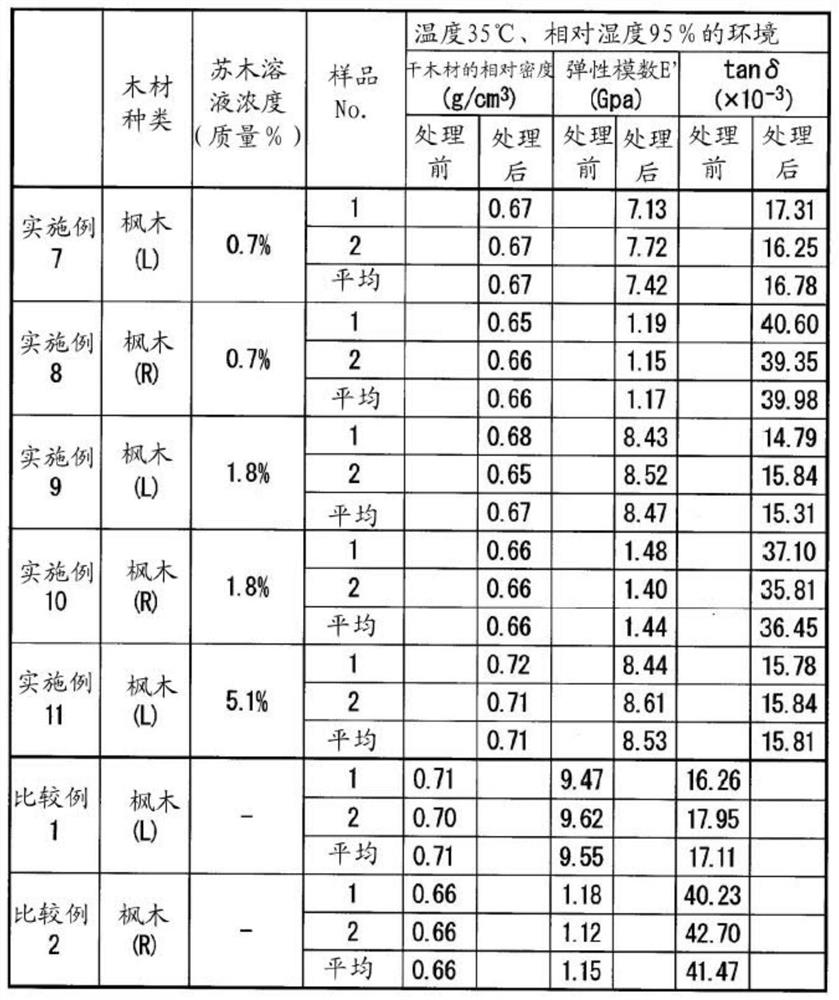

[0111] "Example 1"

[0112] The sumac extract component is extracted from powdered sumac using hot water (extraction process). The mass of the solid component extracted from the sumac by performing the extraction process was 10% of the mass of the sumac.

[0113] Next, water was added to the hematoxylin solution obtained by performing the extraction step to obtain a hematoxylin solution containing 0.7% by mass of the hematoxylin extract component.

[0114] (wood)

[0115] As wood, prepared two (sample No.1, 2) L direction (fiber direction) length 180mm, R direction (radius direction) length 20mm, the maple wood (hereinafter referred to as maple ( L)).

[0116] Next, each maple (L) was heated in an oven at a temperature of 105° C. until the quality became stable and completely dry, and the mass was measured (before the treatment in Table 1). Each maple wood (L) in an absolutely dry state is subjected to humidity-conditioning treatment at a temperature of 22°C and a relative...

Embodiment 2

[0130] "Example 2"

[0131] As wood, except for using two sheets (sample Nos. 1, 2) of maple (hereinafter referred to as maple ( Except R)), the modified wood of Example 2 was obtained in the same manner as in Example 1.

Embodiment 3

[0132] "Example 3"

[0133] The hematoxylin solution obtained by carrying out the extraction step in the same manner as in Example 1 was heated to evaporate the water contained in the hematoxylin solution to obtain a hematoxylin solution containing 1.8% by mass of the hematoxylin extract component. Modified wood of Example 3 was obtained in the same manner as in Example 1, except that a hematoxylin solution containing 1.8% by mass of the obtained hematoxylin extract component was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com