Automatic equidistant cutting equipment for glass block

An isometric cutting, glass block technology, applied in stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of inconsistent cutting length, scratches on artificial hands, and inability to guarantee straightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

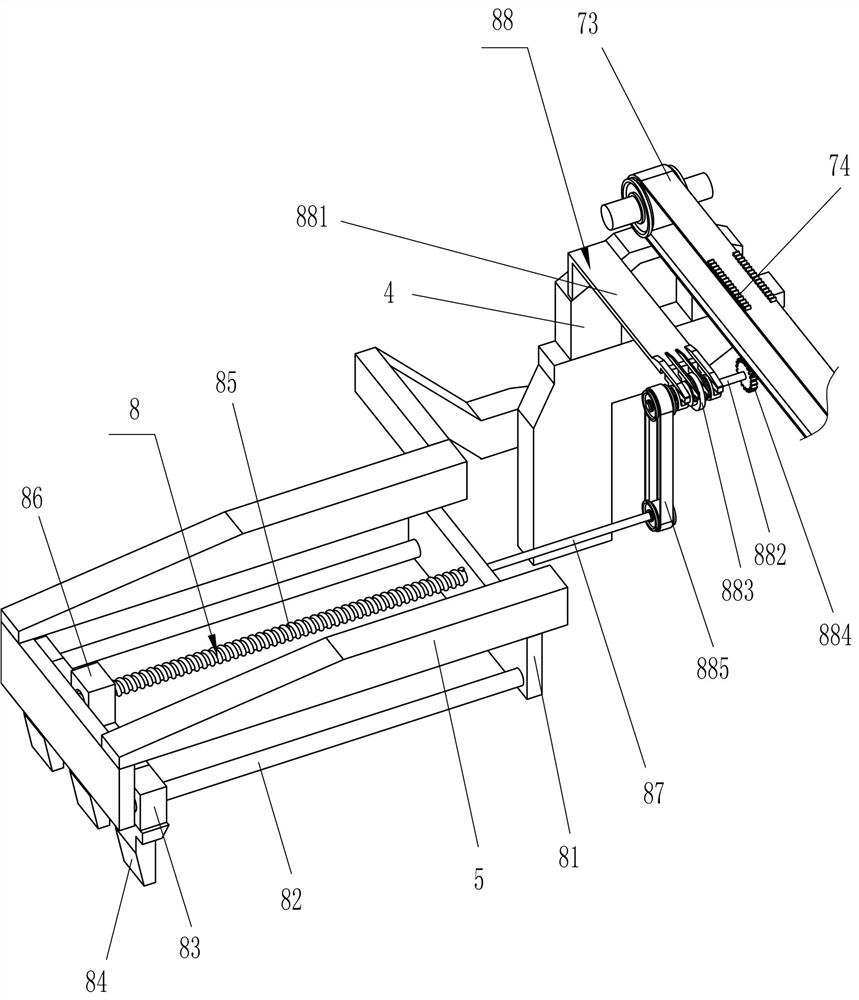

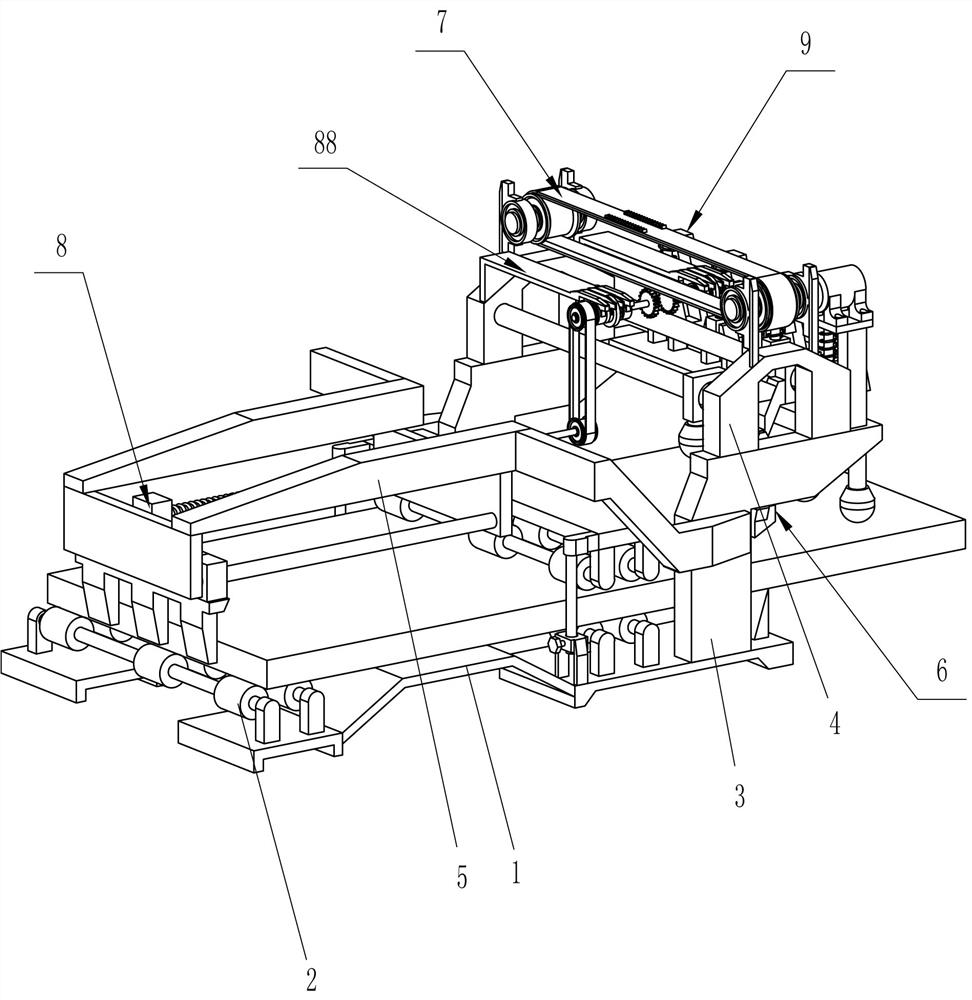

[0028] An automatic equidistant cutting equipment for glass blocks, such as Figure 1-4 As shown, it includes a placement plate 1, a placement wheel 2, a bracket 3, a mounting frame 4, a support frame 5, a cutting device 6, a transmission device 7 and a propulsion device 8, specifically:

[0029] The left and right sides of the upper side of the placement board 1 are connected with placement wheels 2, the upper right side of the placement board 1, the front and rear sides are connected with brackets 3, the upper side of the brackets 3 is connected with the installation frame 4, and the left side of the bracket 3 is connected with a support A cutting device 6 is arranged between the frame 5 and the lower side of the mounting frame 4, a transmission device 7 is provided between the upper side of the mounting frame 4, and a propulsion device 8 is provided between the supporting frames 5.

[0030] When the glass needs to be cut, the glass can be placed on the placement plate 1, th...

Embodiment 2

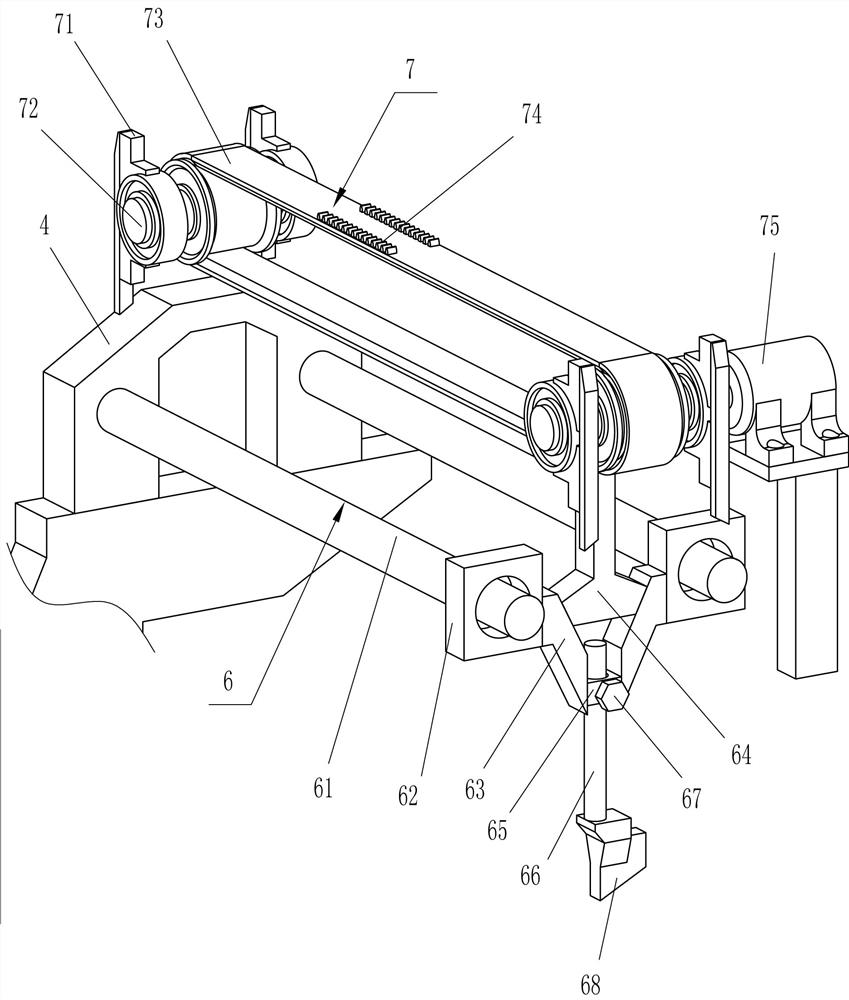

[0032] An automatic equidistant cutting equipment for glass blocks, such as Figure 5-7 As shown, the cutting device 6 includes a first guide rail 61, a first guide sleeve 62, a moving frame 63, a connecting block 64, a second guide sleeve 65, a second guide rail 66, a first fastening bolt 67 and a diamond knife 68, specifically for:

[0033] A first guide rail 61 is connected between the installation frames 4, a first guide sleeve 62 is slidably connected to the first guide rail 61, a mobile frame 63 is connected to the first guide sleeve 62, and a connecting block 64 is connected to the upper side of the mobile frame 63. The connecting block 64 is connected with the transmission device 7, the middle part of the moving frame 63 is connected with a second guide sleeve 65, the second guide sleeve 65 is slidingly connected with a second guide rail 66, and the second guide sleeve 65 is connected with a first fastening bolt 67 , the lower side of the second guide rail 66 is conne...

Embodiment 3

[0045] On the basis of Example 2, such as Figure 8-9 Shown, beating device 9 is also included, and beating device 9 includes fixed seat 91, the 4th guide sleeve 92, the 4th guide rail 93, elastic piece 94, fixed frame 95, beating ball 96, connecting plate 97, rack 98. Fixed plate 99, fourth rotating shaft 910, second ratchet backstop 911, second circular gear 912, third circular gear 913 and second toothed belt 914, specifically:

[0046] The upper right side of the bracket 3 is provided with a beating device 9, which is connected with the first belt drive assembly 73, and the beating device 9 is used to beat and peel off the cut glass. The upper right side of the bracket 3 is connected with a Four sets of fixed seats 91, the fixed seats 91 are connected with the fourth guide sleeve 92, the fourth guide sleeve 92 is slidably connected with the fourth guide rail 93, the fourth guide rail 93 and the fourth guide sleeve 92 are connected with elastic 94, the right side of the fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap